Section E - Hydraulics

Drive Motors

Track Drive Motor

E-27 E-27

9803-9570-4

13 Remove ‘O’ ring 11 and bearing race 12.

14 Drive out oil seal 13, using a plastic hammer, and

remove dust seal 14.

15 Remove needle bearing 15 and bearing race 16.

16 Remove output shaft 17 and retrieve balls 18.

Cleaning and checking

Wash all parts in a weak carbon based solvent.

Check all parts for wear and replace as necessary. Renew

all ‘O’ rings and seals.

Assembly

1 Place the motor housing on a clean soft surface with

the flange pointing upwards.

2 Grease the journals of output shaft 17. Position balls

18 into the holes in the shaft and assemble the shaft

into the housing.

3 Assemble new oil seal 13 and dust seal 14 into spigot

flange 10 using a suitable drift.

4 Place bearing races 12 and 16 and needle bearing 15

into the spigot flange.

5 Slip the spigot flange with assembled seals over the

shaft taking care not to damage the seals.

6 Fit the washers and screws 9 and tighten to 0.6 Nm

(0.44 lbf ft).

7 Turn the motor over so that the shaft points

downwards and place it in the assembly fixture.

8 Place a new ‘O’ ring 8 into the housing seal groove

and fit the channel plate 7.

9 Place carden shaft 6 into the drive shaft hole.

10 Fit new ‘O’ rings 8 into the seal grooves on both sides

of the gear wheel set.

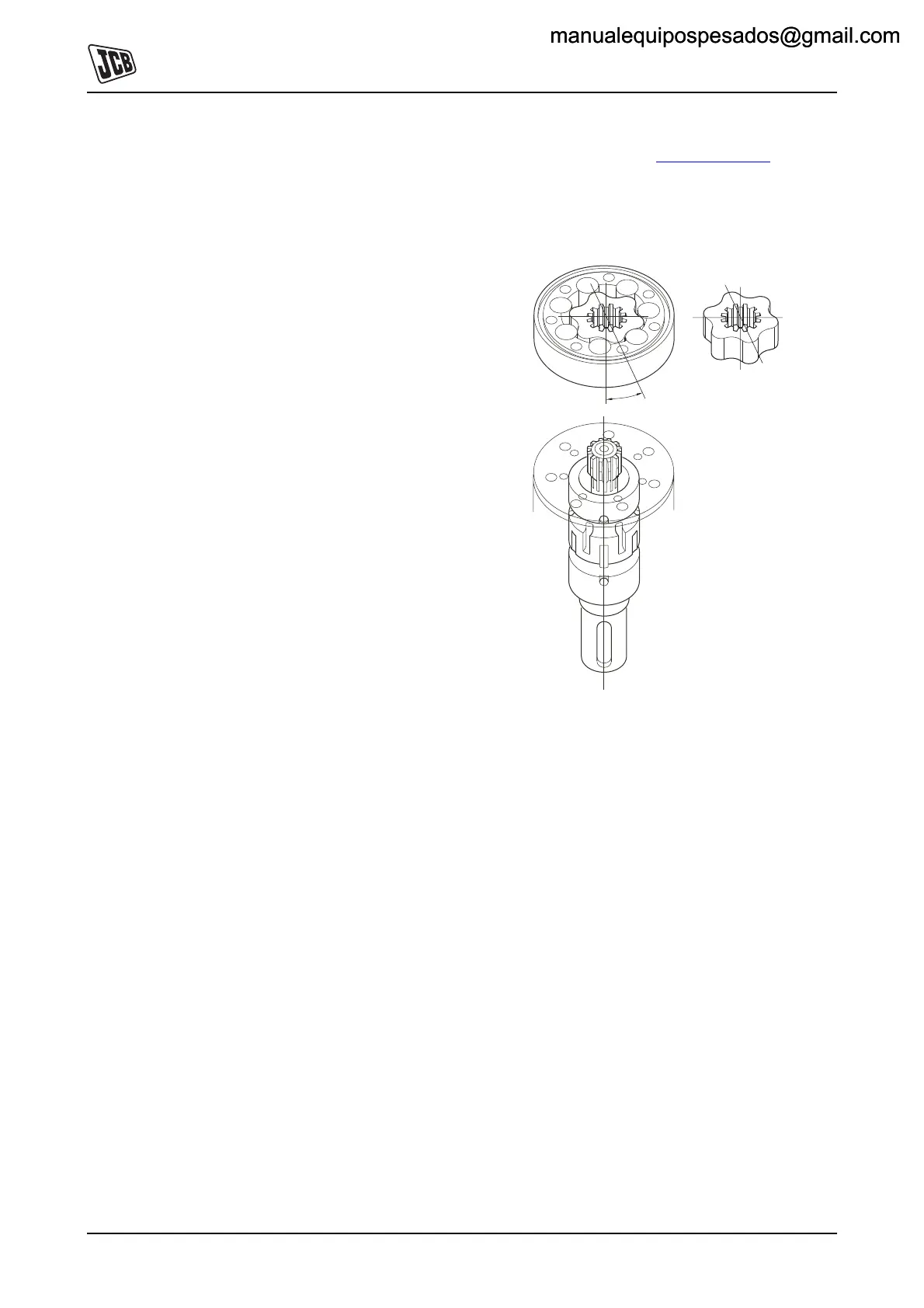

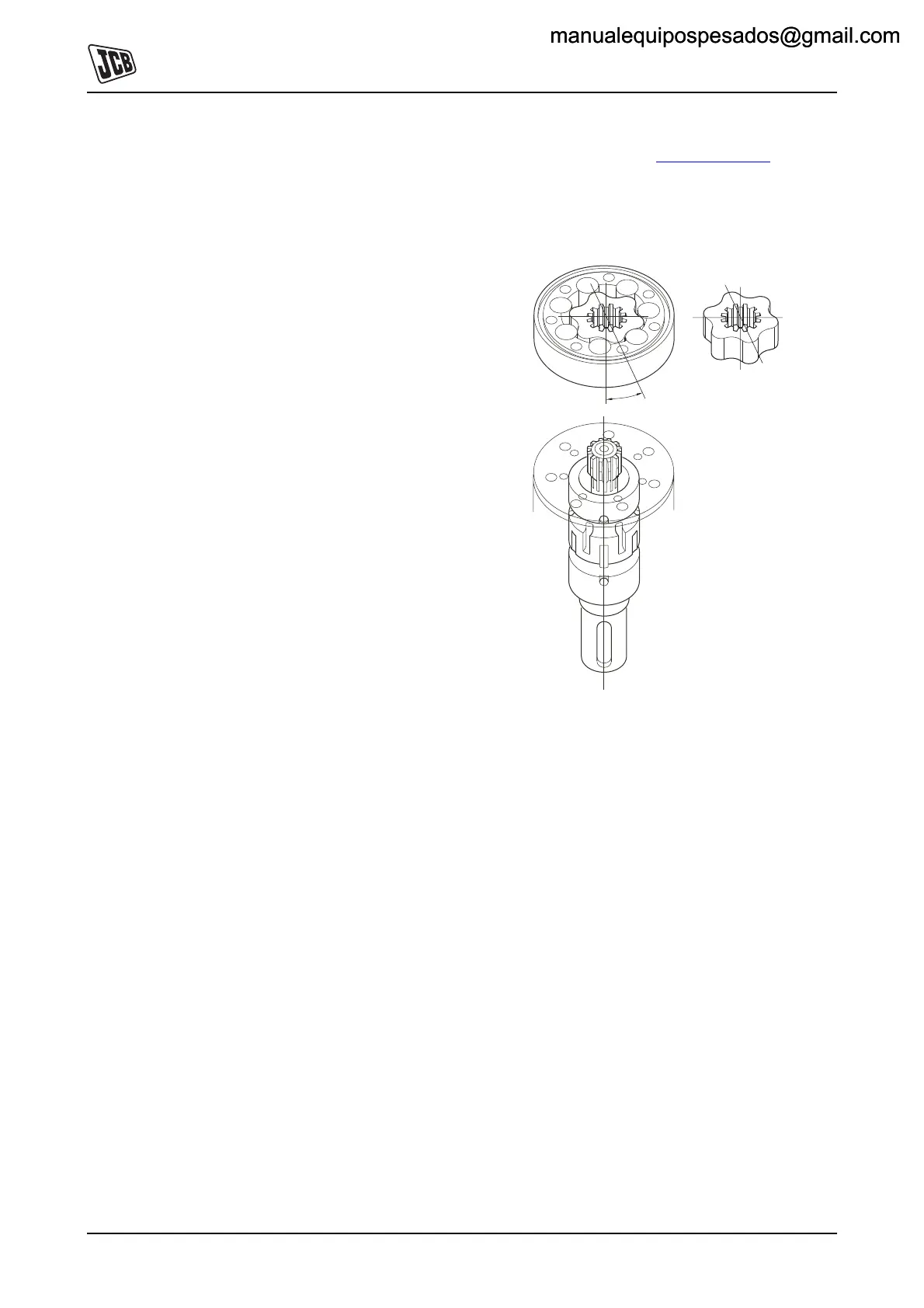

11 To ensure correct direction of rotation, place the gear

wheel set so that the axis passing through two

opposite rotor tooth profiles is at an angle of 15deg to

the axis of the key slot, K

Fig 3. ( T E-27).

The smallest diameter of the stepped bolt holes in the

gear wheel set should be positioned towards the

channel plate.

Fig 3.

12 Place end cover 4 over the gear wheel set and align

the fixing holes.

13 Fit the washers and screws 3 and tighten to 3 Nm (2.2

lbf ft).

14 Refit the drain plug and washer 2.

15 Fit the drive shaft key 1.

15º

manualequipospesados@gmail.commanualequipospesados@gmail.com

Loading...

Loading...