Section J - Tracks

Track Maintenance

Idler Wheel and Recoil Unit

J-12 J-12

9803-9570-4

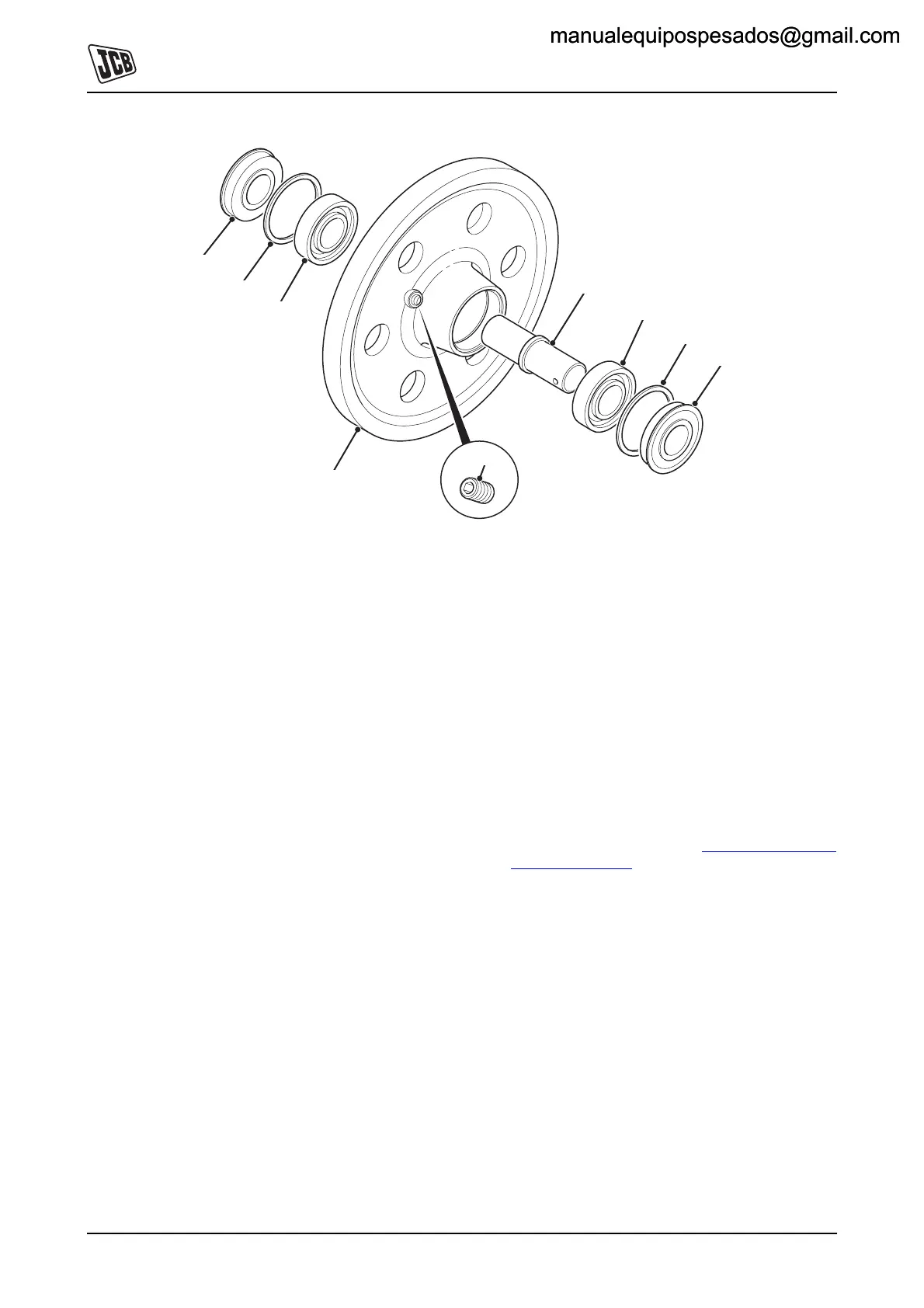

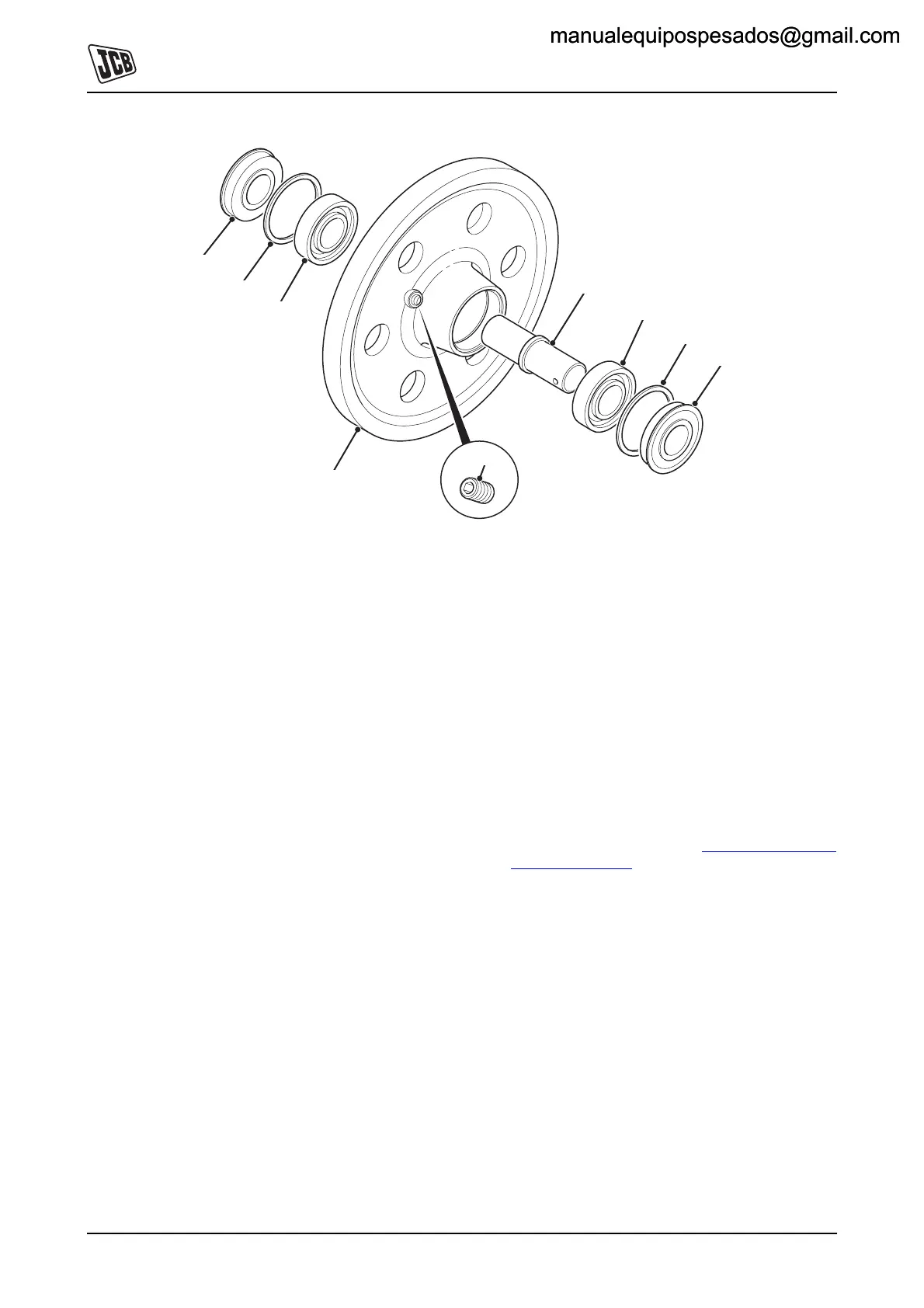

Fig 8.

Idler Wheel - Dismantling and Assembly

Dismantling

1 Prise out seals A and F from the idler wheel.

2 Turn the idler wheel on its side and allow any oil to

drain out.

3 Remove circlips B and G.

4 Drift out shaft C together with bearing E from the idler

wheel.

5 Using a puller remove bearing E from shaft C and

bearing H from idler wheel D.

Note: Bearing H may remove with the shaft.

6 Clean all components and inspect for wear. Renew

bearings if worn or damaged. Renew oil seals

regardless of condition.

Assembly

1 Assemble new bearings E and H onto shaft C.

2 Fit circlip G into groove in idler wheel bore.

3 Push the shaft and bearing assembly into the

opposite end of the idler wheel bore. Ensure that the

bearings are fully against circlip G.

4 Fit circlip B.

5 Press new oil seals A and F into each side of the idler

wheel.

6 Remove plug J and fill the bearing cavity with the

correct grade of oil K

Lubricants and

Capacities ( T 3-8)

7 Refit the plug.

8 Check that the idler wheel rotates freely on its shaft.

A

B

E

C

D

H

G

F

J

manualequipospesados@gmail.commanualequipospesados@gmail.com

Loading...

Loading...