Section J - Tracks

Track Damage

Types of Rubber Track Damage

J-18 J-18

9803-9570-4

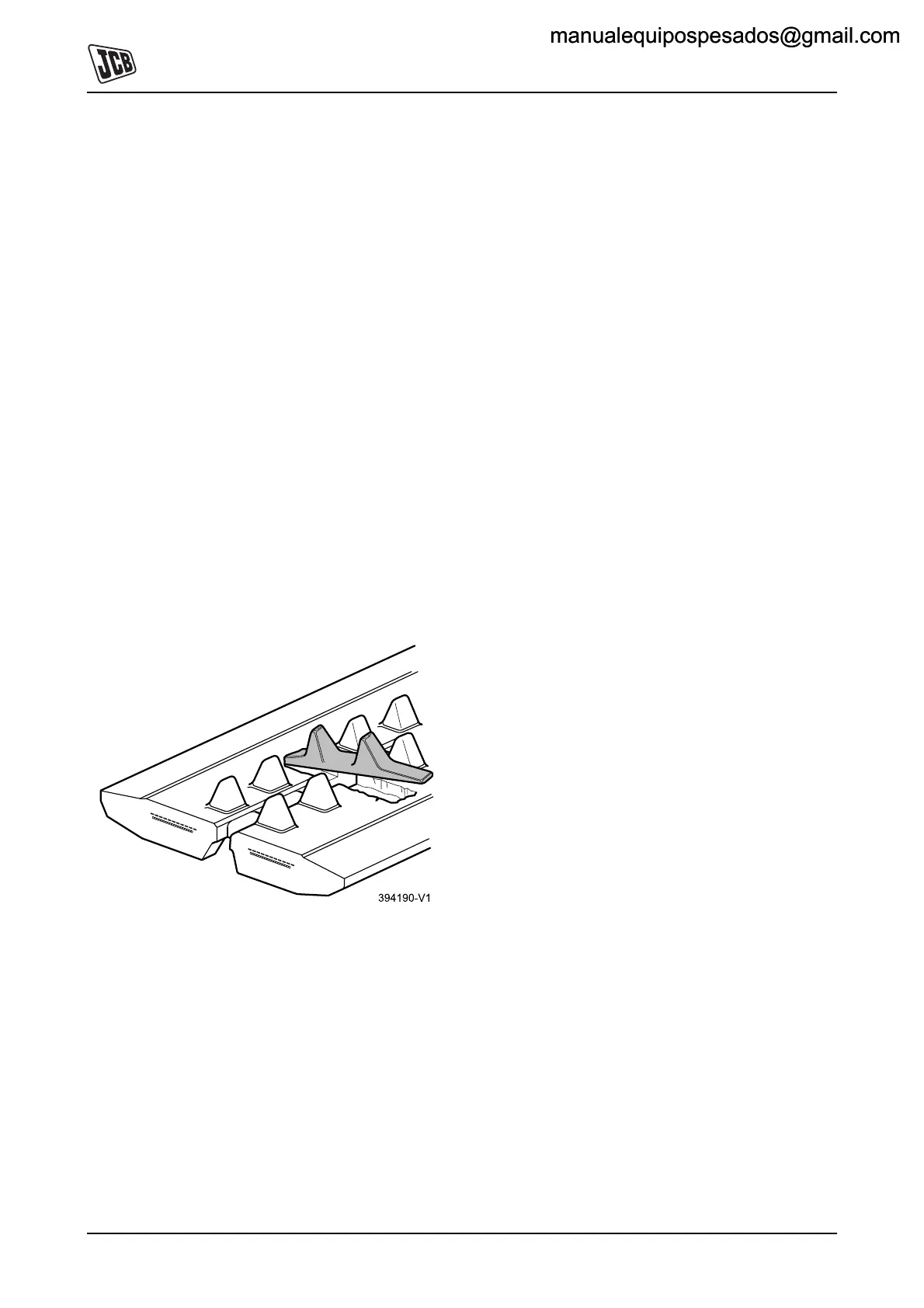

Core Bars - Separation

Cause:

1 Low track tension - the core bars are likely to hit the

running gear components and lead to separation from

the track

2 Hard material (stone, metal) stuck between the top of

two core bars.

3 Sprocket teeth badly worn (hook-shaped).

4 Oxidation (rusting) of the core bars.

Prevention:

1 Check the track tension regularly (as recommended

in service schedules).

2 Clean the tracks regularly as recommended,

particularly after operation in clay soil.

3 When fitting a track on a machine, always make sure

that the sprocket is in good condition. If the sprocket

is damaged it must be changed.

4 Regularly clean and grease the components.

Fig 1.

Additional Notes:

If one or more core bars are separated from the track, the

track must be replaced.

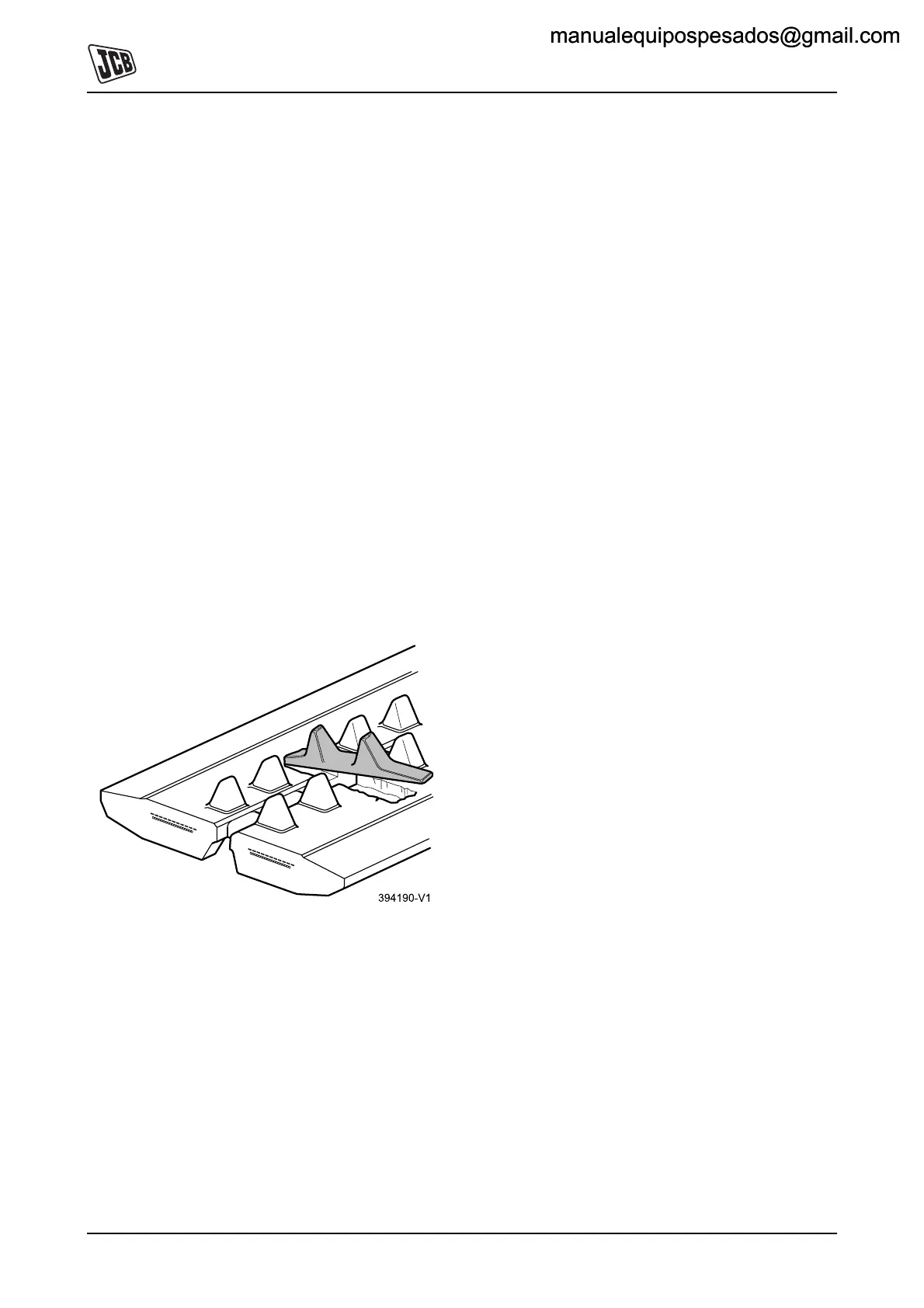

Core Bars - Breaking

Breaking in the middle

Cause:

1 Excessive track tension together with a shock load,

for example, climbing pavement edges.

2 Hard material (stone, metal) stuck between the

sprocket and the core bar with excessive track

tension.

3 Abrasion of the teeth.

4 Idler spring ineffective.

Prevention:

1 Check the track tension regularly (as recommended

in service schedules).

2 Clean the tracks regularly as recommended,

particularly after operation in clay soil.

3 The track is not appropriate for the sprocket. Make

sure that the sprocket is not excessively worn and is

in good condition.

4 Clean the spring if it is clogged (with clay, for

instance) and make sure that it is in working order.

Breaking on the wings

Cause:

1 Only one side of the track is in contact with the

ground, for instance, sitting astride a trench, or

passing over pavement edges at an angle.

Prevention:

1 Always operate the machine on both tracks. Use a

ramp to mount and dismount from pavement edges.

manualequipospesados@gmail.commanualequipospesados@gmail.com

Loading...

Loading...