Chapter - Routine Maintenance

Page Issue 01

OG

6:8

V Range 501 ● 651 ● 801 - Operator’s Guide

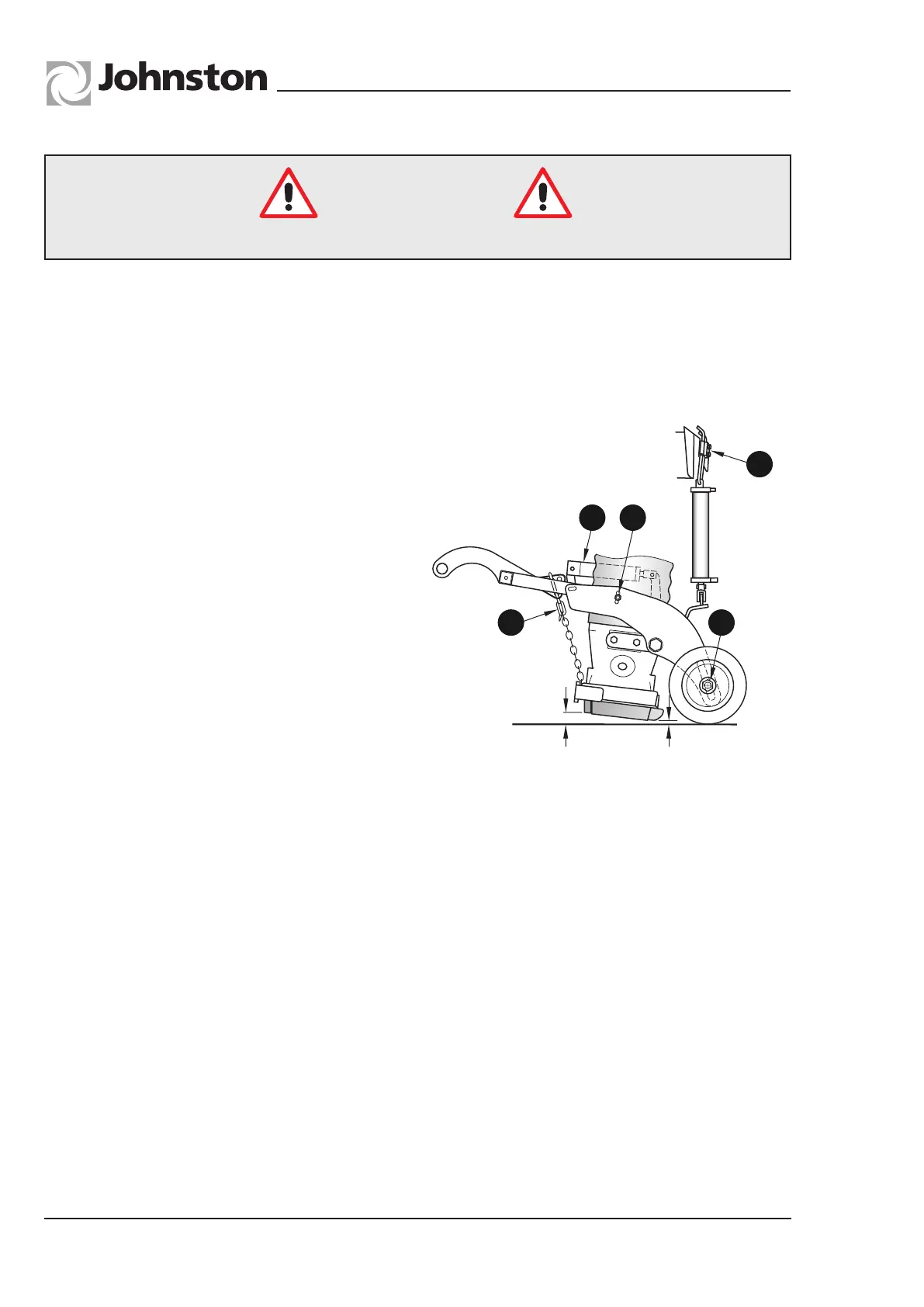

NozzleAdjustment

In order to maximise the performance of the machine It is important that a working clearance

is maintained between the nozzle rubbers and the road surface. The following settings are

recommended as a guide although some conditions may require a tighter front nozzle setting.

Adjustment is carried out with the Maxigap/Varagap in the closed position.

Rear Nozzle Rubber.

Recommended ground clearance

8-10mm.

Adjustment.

Raise or lower the carriage wheels (B)

as required.

Front Nozzle Rubber.

Recommended ground clearance

35-40mm.

Adjustment.

Raise or lower the chain link (A) as

required.

The rear nozzle rubber should always

be approximately 8-10mm from the

ground to allow for the road camber. An

average gap setting between the front

nozzle rubber and the ground has been

found to be 35-40mm for most sweeping

conditions. These adjustments may become necessary as nozzle rubbers and tyres wear.

There must always be sufficient extension (75-100mm) capability in the nozzle trunking and

the nozzle lift cylinder to ensure that the nozzle does not become suspended when passing

over road surface depressions. The attachment of the nozzle lift cylinder to the trunking

bracket may be adjusted downwards by the clamped ‘U’ bolt (C).

Additional adjustment is provided to alter the draw bar height/position. Normally the centre

hole is utilised. Repositioning setscrew (D) into a lower hole raises the front of the nozzle,

or into a higher hole lowers the front of the nozzle.

The Maxigap feature (E) opens the nozzle aperture to allow for the ingestion of bulky

objects.

M02OG-053

35-40mm8-10mm

A B

C

D

E

●TheuseofNeedlestickglovesisrecommendedwhenworkingwiththisequipment

Safety Notice

All Copyright and rights are the property of Johnston Sweepers Ltd

Loading...

Loading...