35

Trouble shooting guide

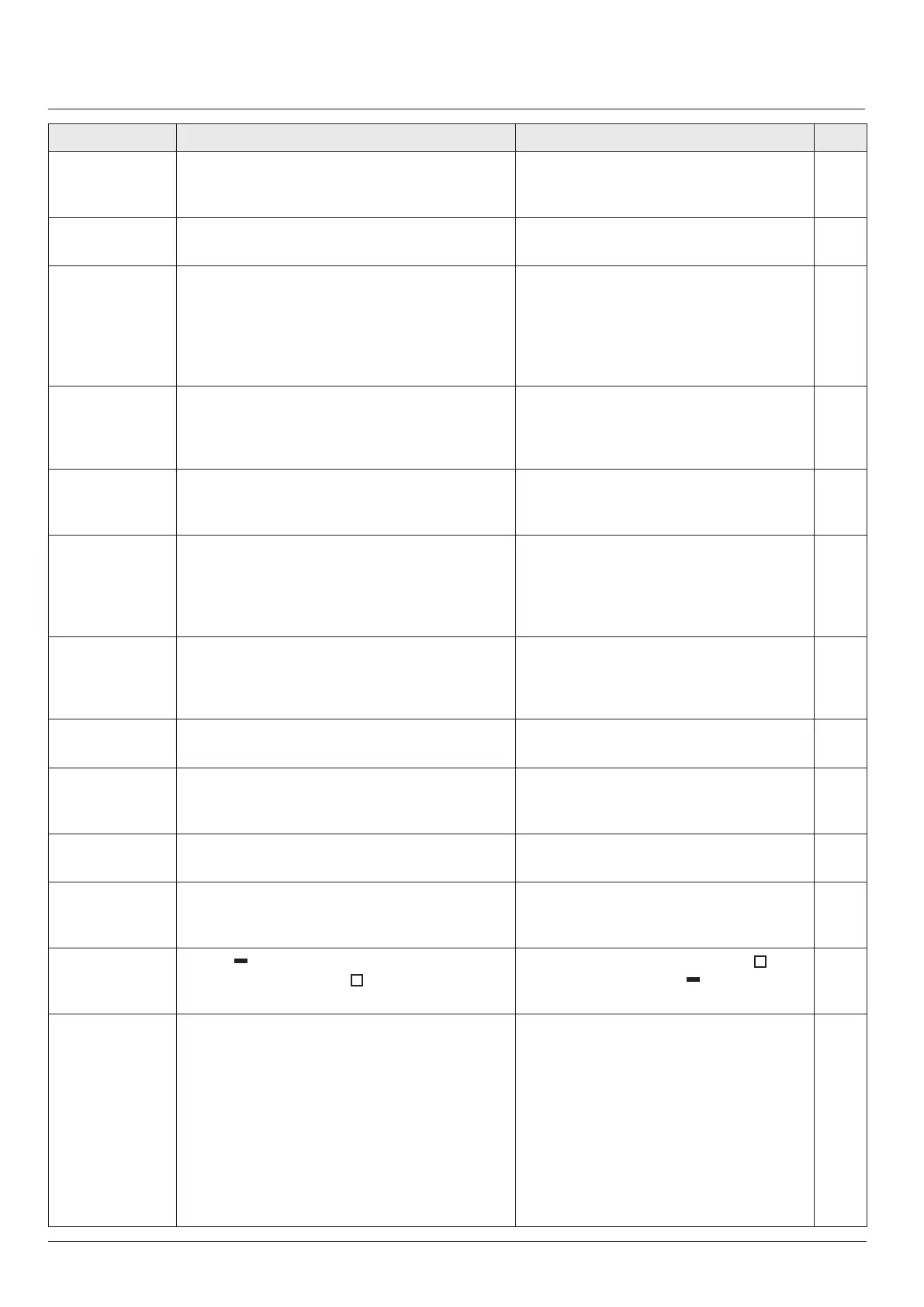

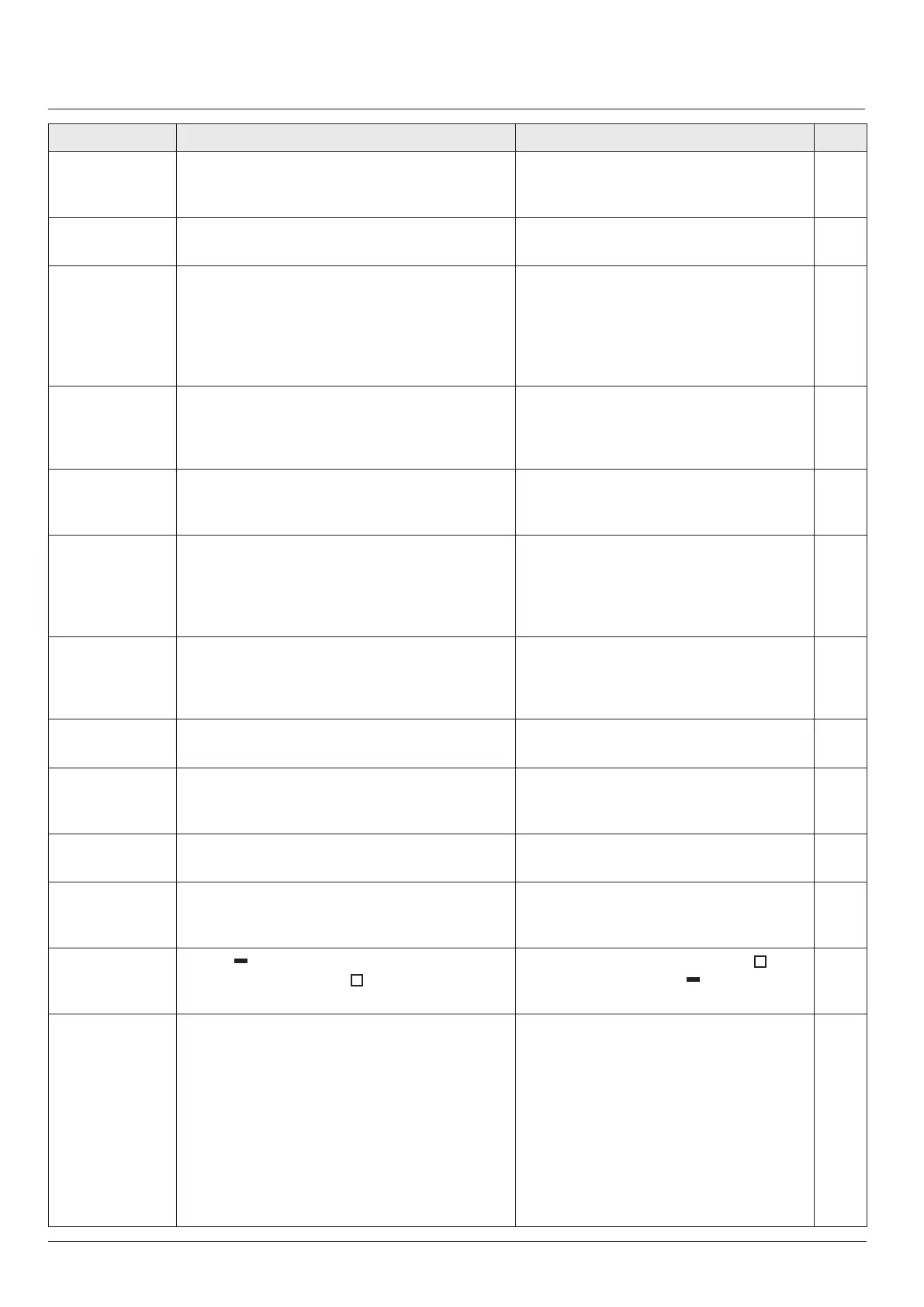

Problem Cause Solution Page

The machine

does not sew:

• Looper or cloth plate cover is open.

• The main switch is not on.

• The machine is not plugged in.

• Close the looper or the cloth plate cover.

• Switch machine on. (Main switch to “I”)

• Insert plug into main socket.

8

8

7

Fabric does not

feed evenly

• Dierential feed is wrongly adjusted.

• Presser foot pressure is too low.

• Check the dierential feed setting.

• Adjust the presser foot pressure.

15

17

Thread breaks • Thread tension is too tight for the thread being

used.

• The machine is not threaded correctly.

• Needles are incorrectly inserted.

• Wrong needles.

• Reduce thread tension.

• Check the threading.

• Insert needles fully into needle clamp with

at side to the back.

• Use needle system 130/705H or JLx2.

26

20

11

11

Needles break • Needles are bent or blunt, points are damaged.

• Needles are not inserted correctly.

• Fabric was pulled while sewing.

• Replace needles.

• Insert needles fully into needle clamp with

at side to the back.

• Guide fabric gently with both hands.

12

11

--

Skipped stitches • Needles are bent or blunt.

• Wrong needles used.

• Presser foot pressure is too low.

• Replace the needles.

• Use needle system 130/705H or JLx2.

• Increase presser foot pressure.

11

11

17

Poor stitch forma-

tion

• Threads are not correctly between the tension

dials.

• Thread has got caught.

• Machine is incorrectly threaded.

• Check if thread is lying between tension

discs.

• Raise the presser foot and pull the thread.

• Check threading path of each thread.

• Check threading path of each thread.

18

18

20

20

Seams ute or

wave, especial-

ly when sewing

knits

• Fabric was pulled while sewing.

• Presser foot pressure is too tight.

• Dierential feed is set incorrectly.

• Guide fabric gently.

• Reduce presser foot pressure.

• Adjust dierential feed to N - 2.

--

17

15

Seams pucker • Needle thread tension is too tight.

• Dierential feed is set incorrectly.

• Reduce the needle thread tension.

• Adjust dierential feed to 0.7 - N.

26

15

Fabric edges curl • Too much fabric is in the stitch.

• Thread tension is too tight.

• Stitch selection lever is on roll hem.

• Reduce cutting width.

• Reduce thread tension.

• Set selection lever to overlock.

13

26

16

Thread loops are

too loose

• Too little fabric in the stitch. • Increase the cutting width. 13

Motor failure • Noise is heard.

• Motor does not turn at all.

• Sparks are abnormally large.

• Replace the carbon brush with a new one.

(Note) Contact your distributor to ask for the

replacement of the carbon brush.

--

Needle eyelet

cannot be thread-

ed

• The “

” marking on the side of the front cover

is not aligned with the “

” marking on the

handwheel.

• Turn the handwheel to align the “

”

marking on it with the “

” marking on the

side of the front cover.

22,23

Upper and lower

loopers cannot be

threaded

• When the handwheel is not xed.

• When the thread is not inserted into the bottom

of the threading hole.

• When the thread is not slacked before the

threading hole.

• When the thread is caught somewhere in the

thread path.

• When the pipe is clogged with lint.

• Raise the threading changeover lever and

turn the handwheel to x it.

• Insert the thread into the threading hole

by 1 to 2 cm.

• Slack the thread before the threading

hole.

• Remove the thread from the location

where it has been caught.

• Thread the loopers by means of the loop-

er threader supplied in the accessory bag

to remove the lint in the pipe.

20,21

20,21

20,21

--

24

Loading...

Loading...