4.6.1 Raising a load

Requirements

– Load correctly palletised.

– Load weight matches the truck's capacity.

– Load handler evenly loaded for heavy loads.

Z

In the case of eccentric loading, the forks are

slightly bent and twisted, which leads to variations

in the weighing results. In the case of inclinations

greater than 2°, holes and unevenness in the floor,

the accuracy of the weighing system decreases by

approx. 0.1% per degree.

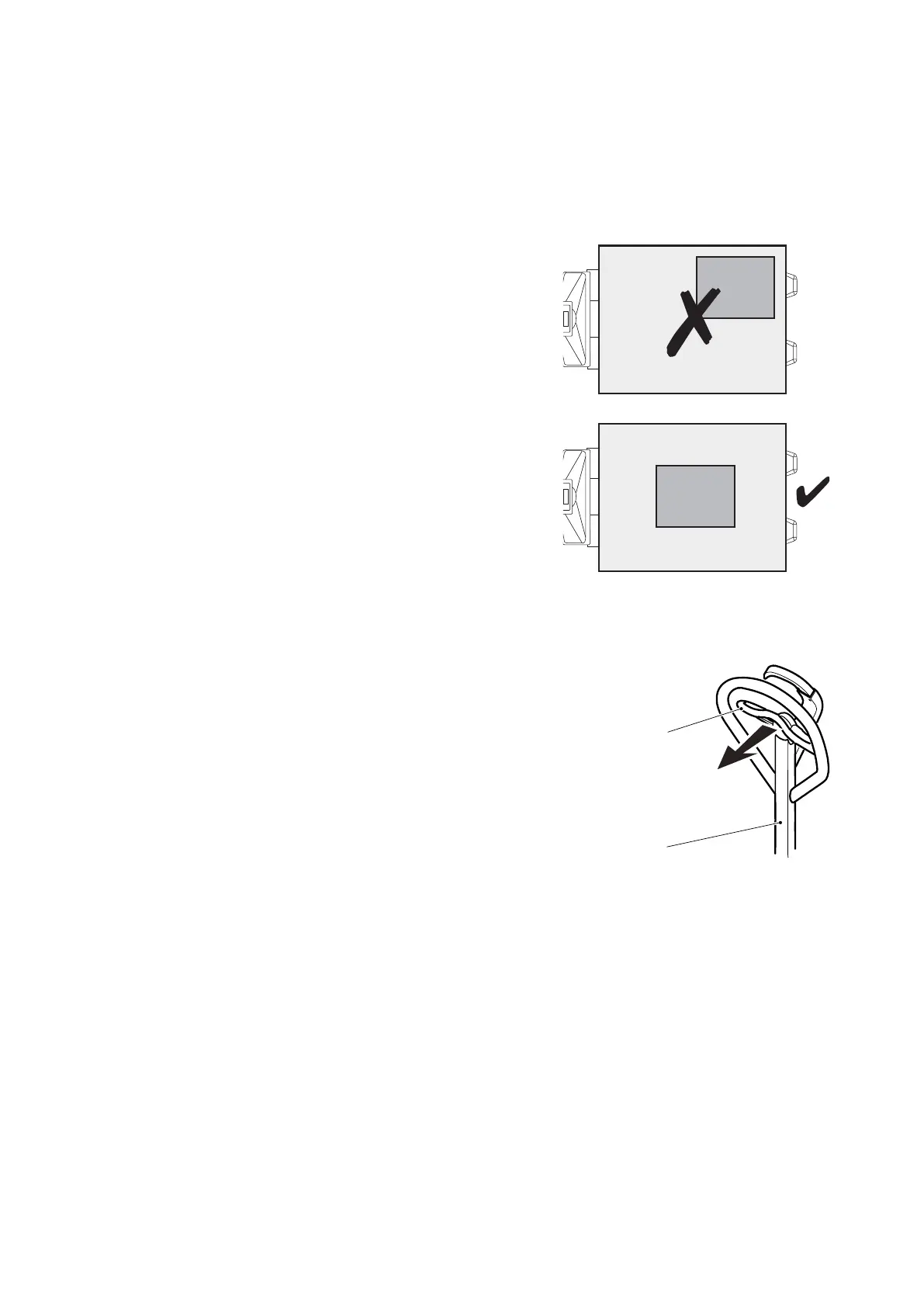

Precise weighing results are obtained only when

the load centre is between the forks. A smooth flat

floor is required to ensure optimum weighing

accuracy.

Calibrated weighing system (o) (only AMW 22p

and AMW 22ps):

In the case of eccentric loading or inclinations

greater than 2°, the display is blocked. The truck

must be centrally loaded and standing on level

ground.

Procedure

• Drive the truck slowly up to the pallet.

• Push the handle (4) in the "H" direction.

• Slowly insert the load handler into the pallet until the

fork shank touches the pallet.

Z

The load must not extend more than 50 mm beyond the

fork tips.

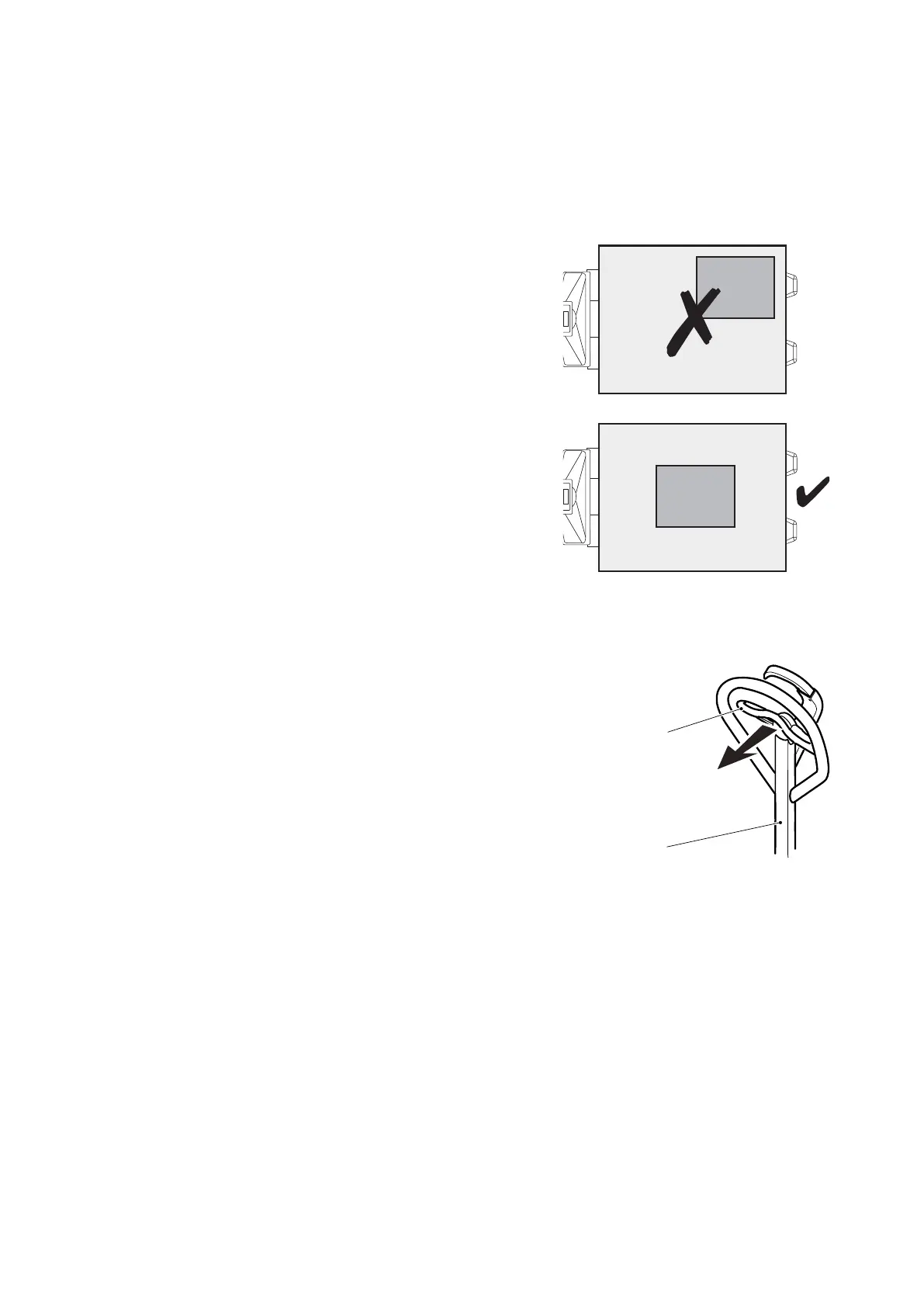

• Lift the load handler by moving the tiller (5) up and

down until you reach the desired lift height.

Z

With rapid lift (up to 120 kg load, (t)), tiller movements

generate significantly greater lift movements.

58

11.19 en-GB

Loading...

Loading...