F 3

0708.GB

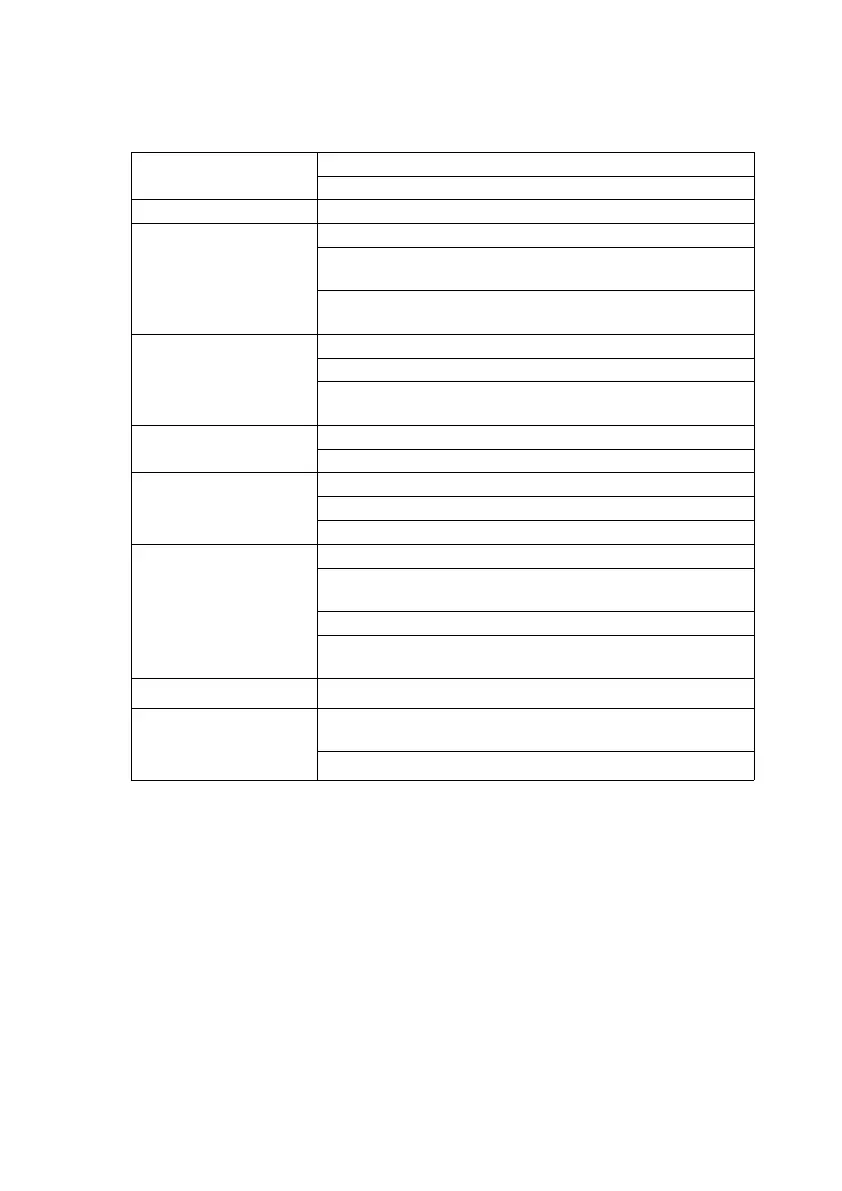

3 Maintenance checklist

A

To ensure safe operation and a long service life of the truck, the activities listed in the

maintenance checklist must be carried out every 6 months.

A

W1 service intervals are to be performed by the customer.

In the run-in period - after approx. 100 service hours - or after repair work, the owner

must check the wheel nuts/bolts and re-tighten if necessary.

Chassis /

superstructure:

Check all load bearing elements for damage

Check all bolted connections

Drive unit: Check the transmission for noises and leakage

Wheels: Check for wear and damage

Check the wheel bearings and ensure secure fastening of

wheels

Check that the wheel bolts are firmly seated; tighten if

necessary

Steering / brake system: Check the steering bearing play

Performance and adjustment check

Check the braking function of the gas pressure spring;

check the gas pressure spring for leakage and damage

Lifting device: Check for proper functioning and wear

Check load section and kinematics for wear and damage

Hydraulic system: Performance check

Check hydraulic unit for tightness and damage

Check the oil level

Electrical system: Performance check

Check cable for tight seating of connections and for

damage

Check the fuses for correct amperage

Check the warning systems and safety circuits for correct

functioning

Electric motors:

Check motor for secure attachment

Batteries:

Check the terminals for secure attachment and apply

grease

Check the battery cables for damage; renew if necessary

F 3

0708.GB

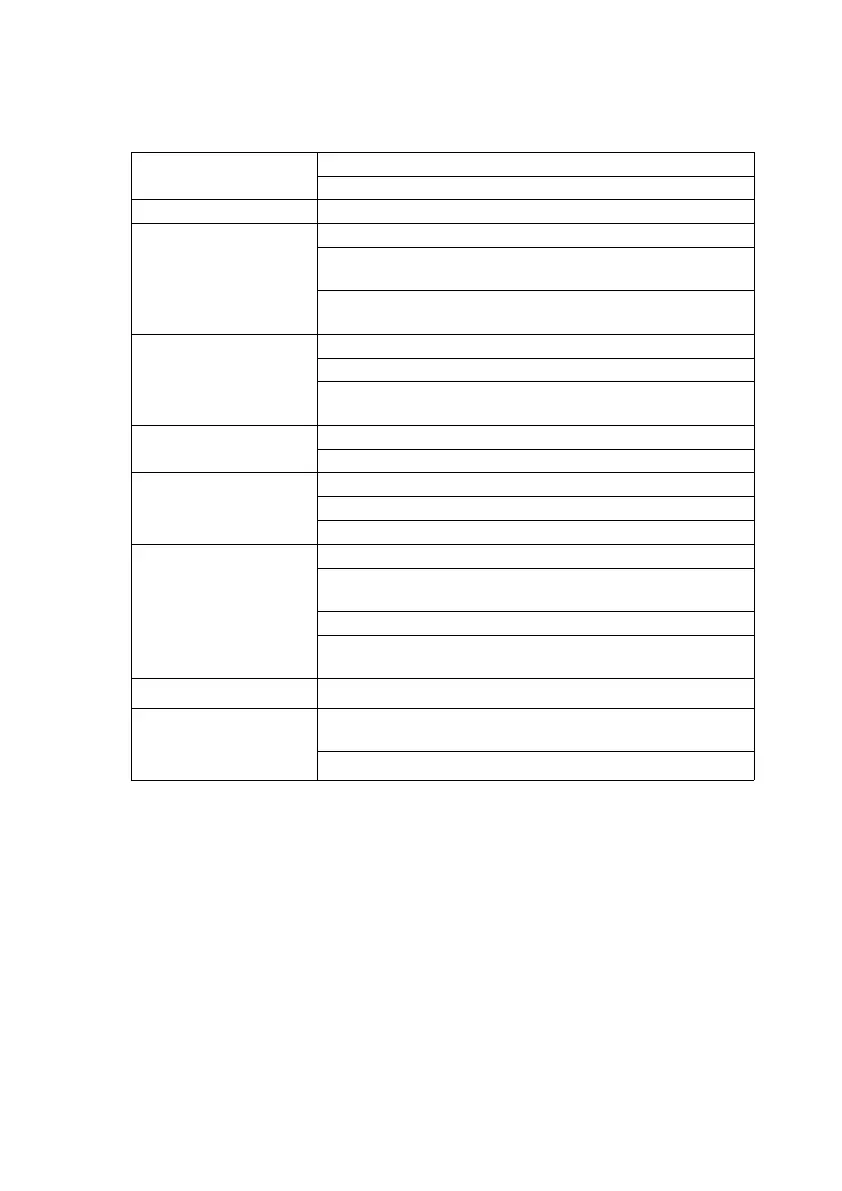

3 Maintenance checklist

A

To ensure safe operation and a long service life of the truck, the activities listed in the

maintenance checklist must be carried out every 6 months.

A

W1 service intervals are to be performed by the customer.

In the run-in period - after approx. 100 service hours - or after repair work, the owner

must check the wheel nuts/bolts and re-tighten if necessary.

Chassis /

superstructure:

Check all load bearing elements for damage

Check all bolted connections

Drive unit: Check the transmission for noises and leakage

Wheels: Check for wear and damage

Check the wheel bearings and ensure secure fastening of

wheels

Check that the wheel bolts are firmly seated; tighten if

necessary

Steering / brake system: Check the steering bearing play

Performance and adjustment check

Check the braking function of the gas pressure spring;

check the gas pressure spring for leakage and damage

Lifting device: Check for proper functioning and wear

Check load section and kinematics for wear and damage

Hydraulic system: Performance check

Check hydraulic unit for tightness and damage

Check the oil level

Electrical system: Performance check

Check cable for tight seating of connections and for

damage

Check the fuses for correct amperage

Check the warning systems and safety circuits for correct

functioning

Electric motors:

Check motor for secure attachment

Batteries:

Check the terminals for secure attachment and apply

grease

Check the battery cables for damage; renew if necessary

Loading...

Loading...