0708.GB

F 4

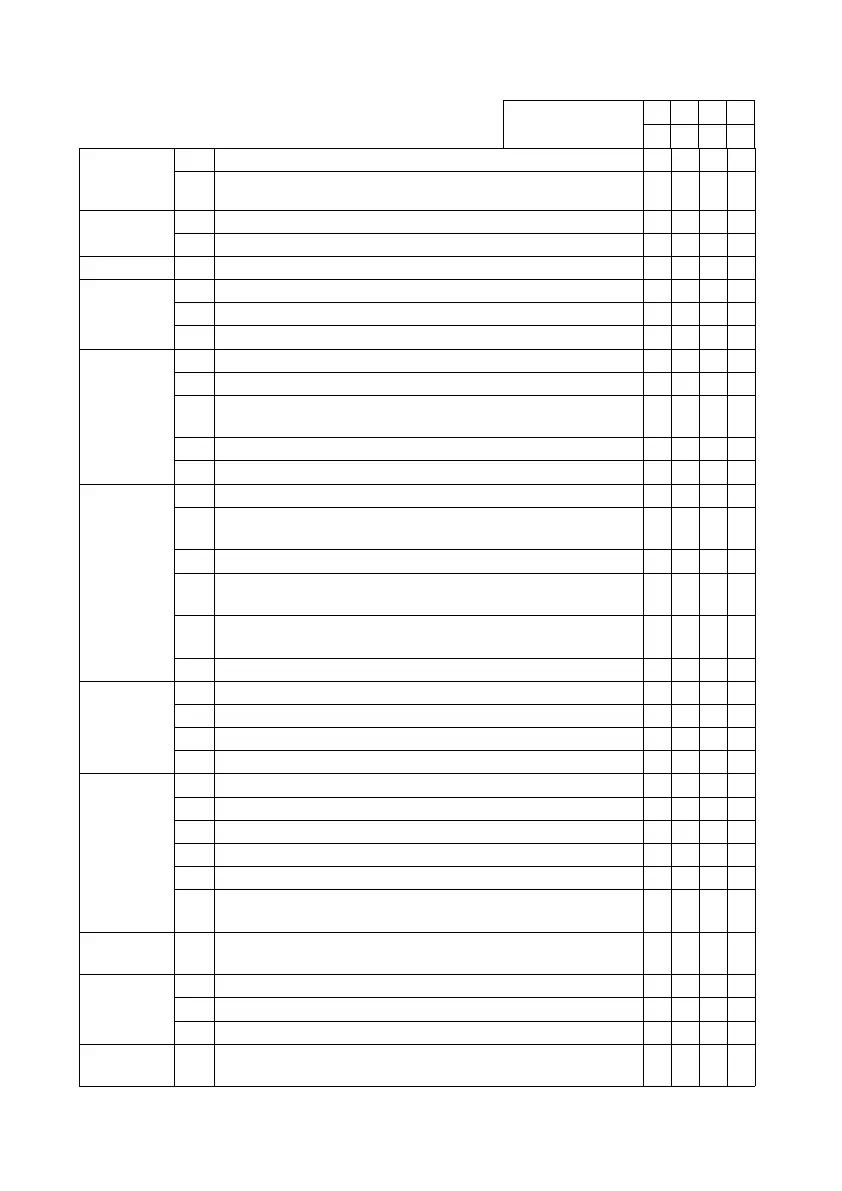

4 Maintenance checklist

Maintenance Intervals

Standard = t WA BC

Cold store = k

Chassis/

Super-

structure:

1.1 Check all load bearing components for damage t

1.2 Check screw connections t

Wheels: 3.1 Check wheels for wear and damage t

3.2 Check suspension and attachment kt

Steering: 4.1 Check slack t

Brake

system:

5.1 Test operation and settings kt

5.2 Test recuperating function t

5.3 Check the brake lining wear t

Hydraulic

System:

6.1 Test operation kt

6.2 Check unions and connections for leaks and damage kt

6.3 Check hydraulic cylinder for leaks and damage and make

sure it is secure

kt

6.5 Replace hydraulic oil kt

6.6 Test operation of pressure relief valves kt

Electrical

system:

7.1 Test operation t

7.2 Make sure wire connections are secure and check for

damage

t

7.3 Check fuse ratings t

7.4 Test switches and trip cams and make sure they are

secure

t

7.5 Check contactors and relays; if necessary replace any

worn parts

t

7.6 Test all warning devices and safety switches. kt

Battery: 9.1 Check acid density, acid level and cell voltage kt

9.2 Check terminals are securely attached, and apply grease kt

9.3 Clean battery connections, make sure they are tight kt

9.4 Check battery cables for damage, replace if necessary. t

Mast: 10.1 Visually inspect rollers, slide pieces and stops kt

10.2 Check forks and fork carriage for wear and damage kt

10.3 Check mast attachment t

10.4 Check lift chains and guides for wear, adjust and lubricate. t

10.5 Check lateral slack and ensure mast sections are parallel t

10.6 Check protective mechanisms for damage and make sure

they are secure

kt

Lubri-

cation:

11.1 Lubricate truck in accordance with Lubrication Schedule. kt

General

measure-

ments:

12.1 Check electrical system for frame leakage t

12.2 Test lift and lowering speeds t

12.3 Test safety devices and cutouts t

Demon-

stration:

13.1 After carrying out maintenance, present the truck to the

supervisor.

kt

0708.GB

F 4

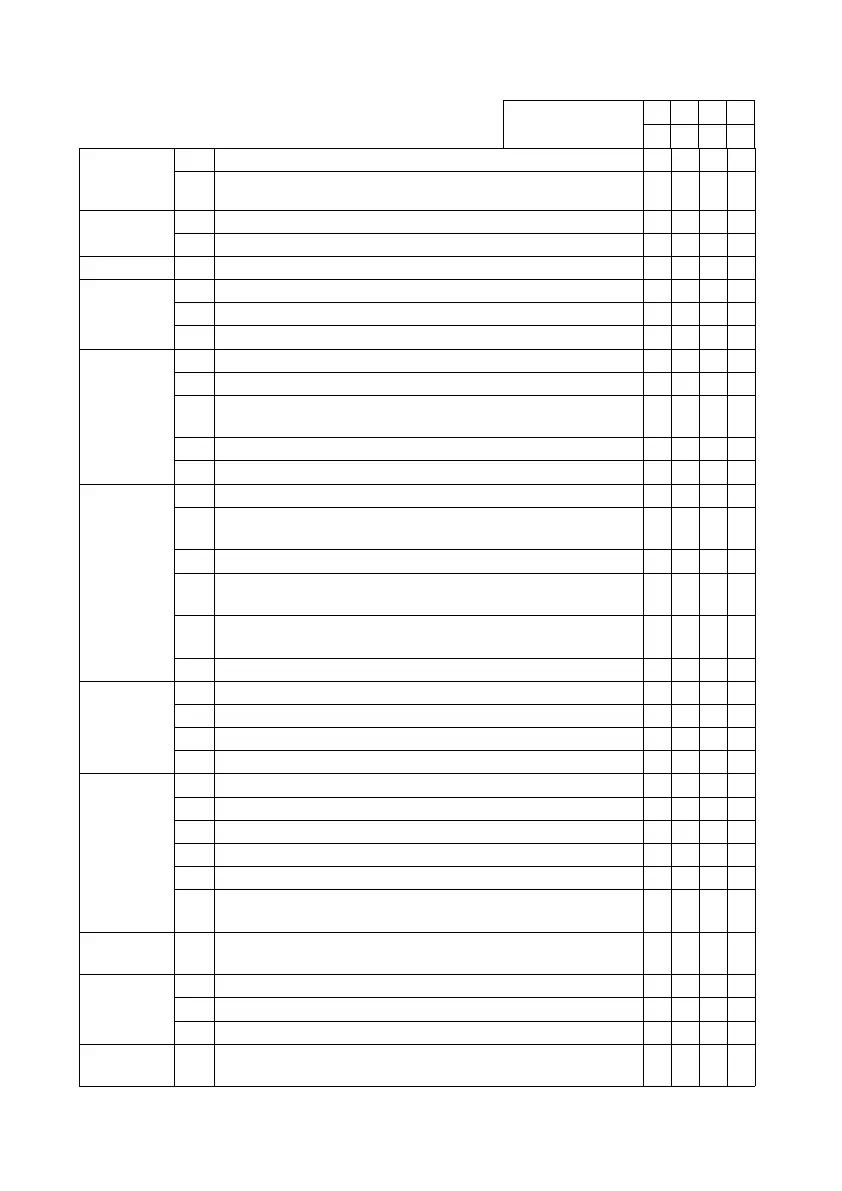

4 Maintenance checklist

Maintenance Intervals

Standard = t WA BC

Cold store = k

Chassis/

Super-

structure:

1.1 Check all load bearing components for damage t

1.2 Check screw connections t

Wheels: 3.1 Check wheels for wear and damage t

3.2 Check suspension and attachment kt

Steering: 4.1 Check slack t

Brake

system:

5.1 Test operation and settings kt

5.2 Test recuperating function t

5.3 Check the brake lining wear t

Hydraulic

System:

6.1 Test operation kt

6.2 Check unions and connections for leaks and damage kt

6.3 Check hydraulic cylinder for leaks and damage and make

sure it is secure

kt

6.5 Replace hydraulic oil kt

6.6 Test operation of pressure relief valves kt

Electrical

system:

7.1 Test operation t

7.2 Make sure wire connections are secure and check for

damage

t

7.3 Check fuse ratings t

7.4 Test switches and trip cams and make sure they are

secure

t

7.5 Check contactors and relays; if necessary replace any

worn parts

t

7.6 Test all warning devices and safety switches. kt

Battery: 9.1 Check acid density, acid level and cell voltage kt

9.2 Check terminals are securely attached, and apply grease kt

9.3 Clean battery connections, make sure they are tight kt

9.4 Check battery cables for damage, replace if necessary. t

Mast: 10.1 Visually inspect rollers, slide pieces and stops kt

10.2 Check forks and fork carriage for wear and damage kt

10.3 Check mast attachment t

10.4 Check lift chains and guides for wear, adjust and lubricate. t

10.5 Check lateral slack and ensure mast sections are parallel t

10.6 Check protective mechanisms for damage and make sure

they are secure

kt

Lubri-

cation:

11.1 Lubricate truck in accordance with Lubrication Schedule. kt

General

measure-

ments:

12.1 Check electrical system for frame leakage t

12.2 Test lift and lowering speeds t

12.3 Test safety devices and cutouts t

Demon-

stration:

13.1 After carrying out maintenance, present the truck to the

supervisor.

kt

Loading...

Loading...