Technical Specification

2 --- 6

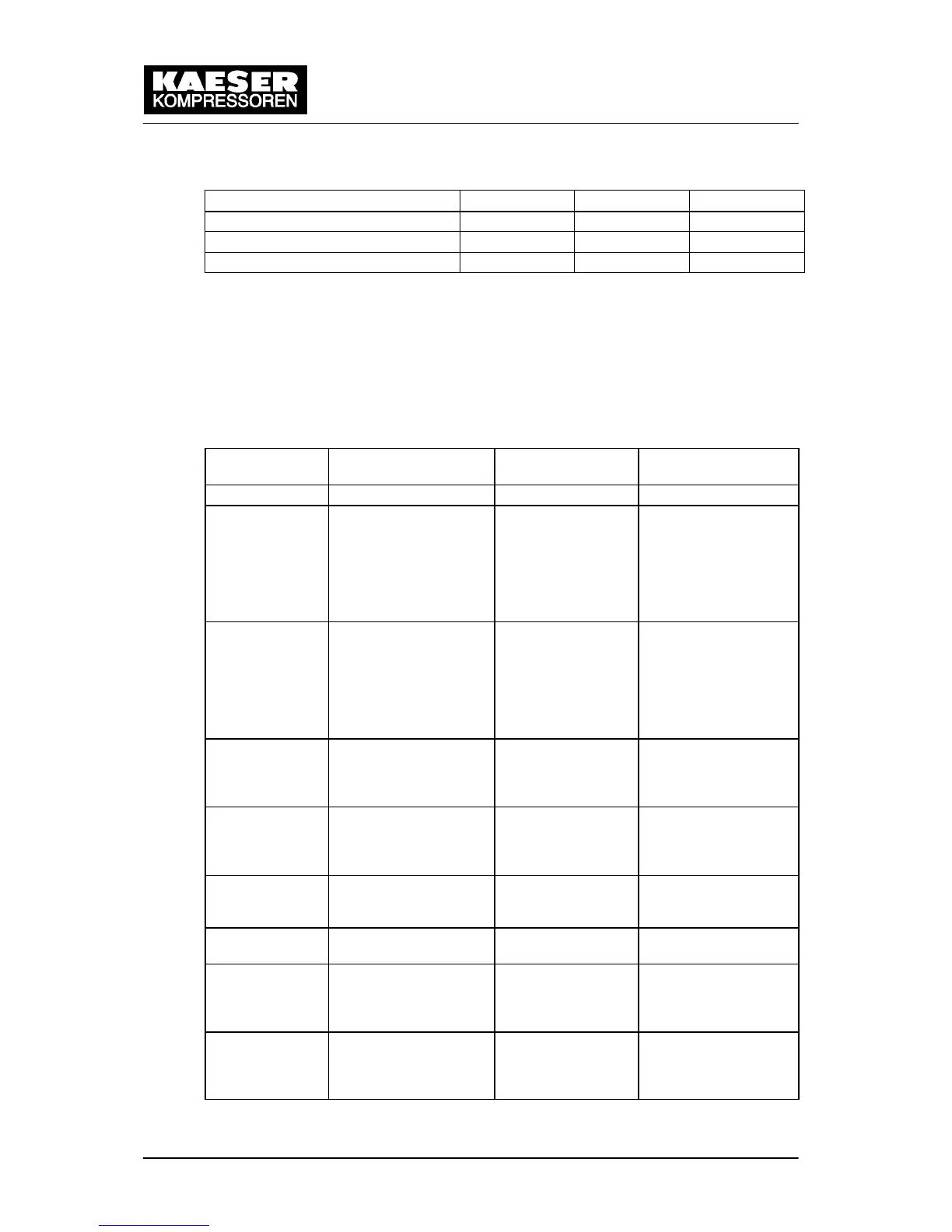

Water Cooling (option K2)

CSD 82 CSD 102 CSD 122

Rated power [kW]** 0,12 /0,17 0,12 /0,17 0,12 /0,17

Nominal speed [rpm]** 2500 / 2700 2500 / 2700 2500 / 2700

Enclosure protection IP 54 IP 54 IP 54

** 50/60 Hz

Tab. 12 Fan motor data (option K2)

2.8 Cooling oil

Ordering: see ’Spare Parts, Operating Materials, Service’ chapter 11.

2.8.1 Recommended cooling oil

A sticker showing the type of oil filled is to be found near the oil separator filling port.

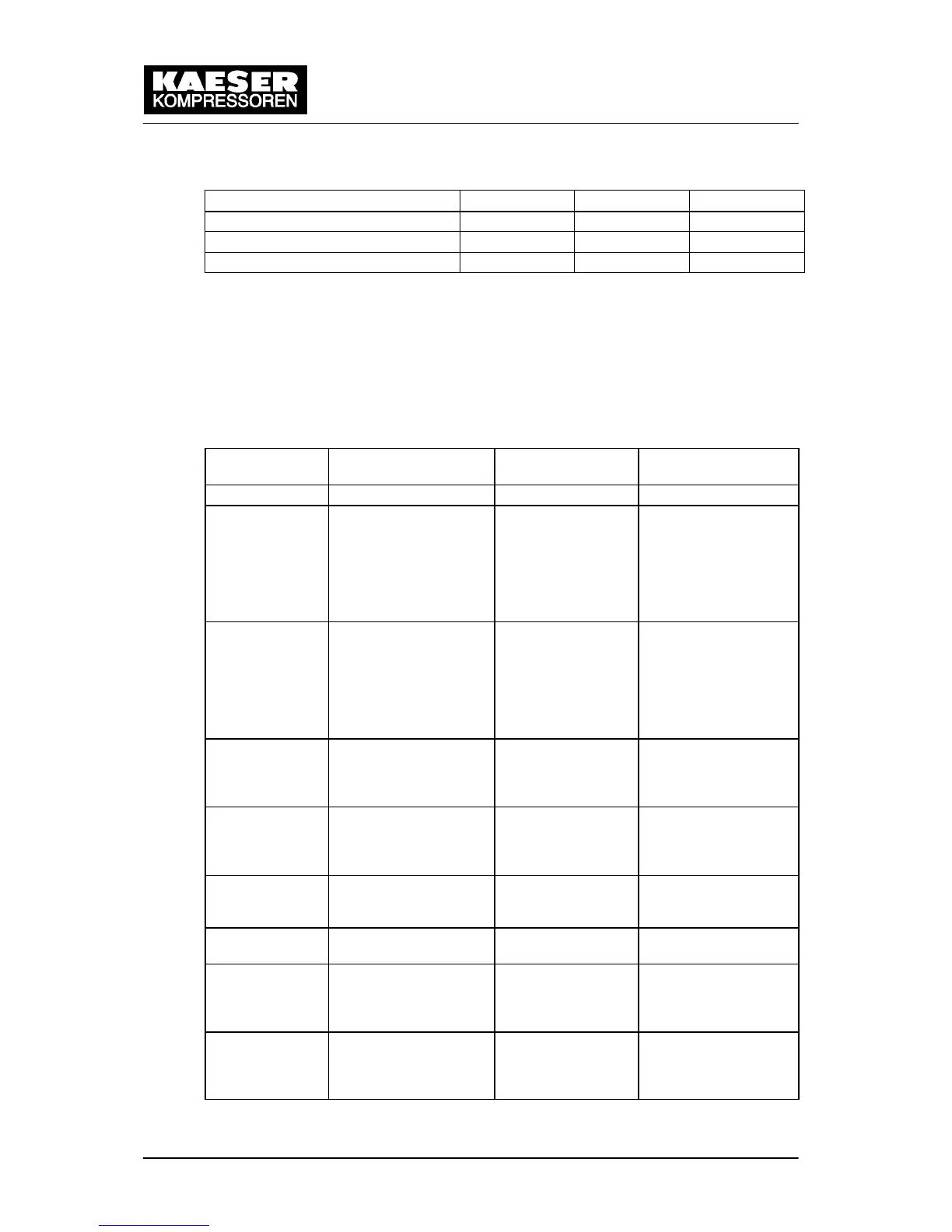

SIGMA

FLUID PLUS / S---460

SIGMA

FLUID MOL

SIGMA

FLUID FGL / FGH

Description Synthetic oil Mineral oil Synthetic oil

Application: Standard oil for all ap-

plications except in

connection with foods-

tuff.

Standard oil for all

applications except

in connection with

foodstuff.

Especially suitable

for lightly utilized

machines.

Specially for use in

compressors where

the air comes in direct

contact with foodstuff.

Authorization — — USDA H–1, NSF

Approved for the

manufacture of foods-

tuff packaging, meat

and poultry proces-

sing and other food

processing.

Viscosity at

40 ˚ C

70 mm

2

/s

(DIN 51562---1) /

45 mm

2

/s

(D 445; ASTM test)

44 mm

2

/s

(DIN 51562---1)

50.7 / 70 mm

2

/s

(D 445; ASTM test)

Viscosity at

100 ˚ C

10.6 mm

2

/s

(DIN 51562---1) /

7,2 mm

2

/s

(D 445; ASTM test)

6.8 mm

2

/s

(DIN 51562---1)

8.2 / 10.4 mm

2

/s

(D 445; ASTM test)

Flash point 260 ˚ C (ISO 2592) /

238 ˚ C

(D 92; ASTM test)

220 ˚ C

(ISO 2592)

254 ˚ C

(D92; ASTM test)

Density at 15 ˚ C 843 / 864 kg/m

3

(ISO 12185)

— —

Pour point ---39 ˚ C

(ISO 3016) /

---46 ˚ C

(D 97; ASTM test)

---33 ˚ C

(ISO 3016)

—

Demulsibility at

54 ˚ C

30 min

(ISO 6614) /

40/40/0/10 min

(D1401; ASTM---Test)

— —

Tab. 13 Recommended cooling oil

Loading...

Loading...