Maintenance

10 --- 72

10.13.6 Start the machine and carry out a test run.

Open the shut---off valve (10, Fig. 30) in the venting line.

Close all access doors; replace and secure all removable panels.

Open the user’s shut---off valve between the machine and the air main.

Switch on the power supply and reset the maintenance interval counter.

Allow the machine to idle for at least one minute. Then switch to LOAD.

After about ten minutes, check the oil level and top up again, if necessary.

Carry out a visual check for leaks.

10.14 Oil filter maintenance

Material: Spare parts

Have the oil container ready.

Pre---condition: Machine switched off

Mains isolator locked off

Machine fully vented (no pressure).

Pressure gauge on the oil separator tank indicates zero.

Danger of burning from hot components and oil.

Wear long---arm clothing and gloves.

Work carefully.

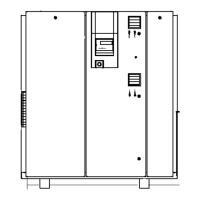

Fig. 35 Changing the Oil Filter

1 Oil filter

2 Direction to unscrew

Dispose of parts and materials contaminated with oil in accordance

with local environment protection regulations.

Unscrew the oil filter anti---clockwise, catch oil spillage and dispose of correctly.

Lightly oil the new oil filter gasket.

CAUTION

Loading...

Loading...