Maintenance

10 --- 61

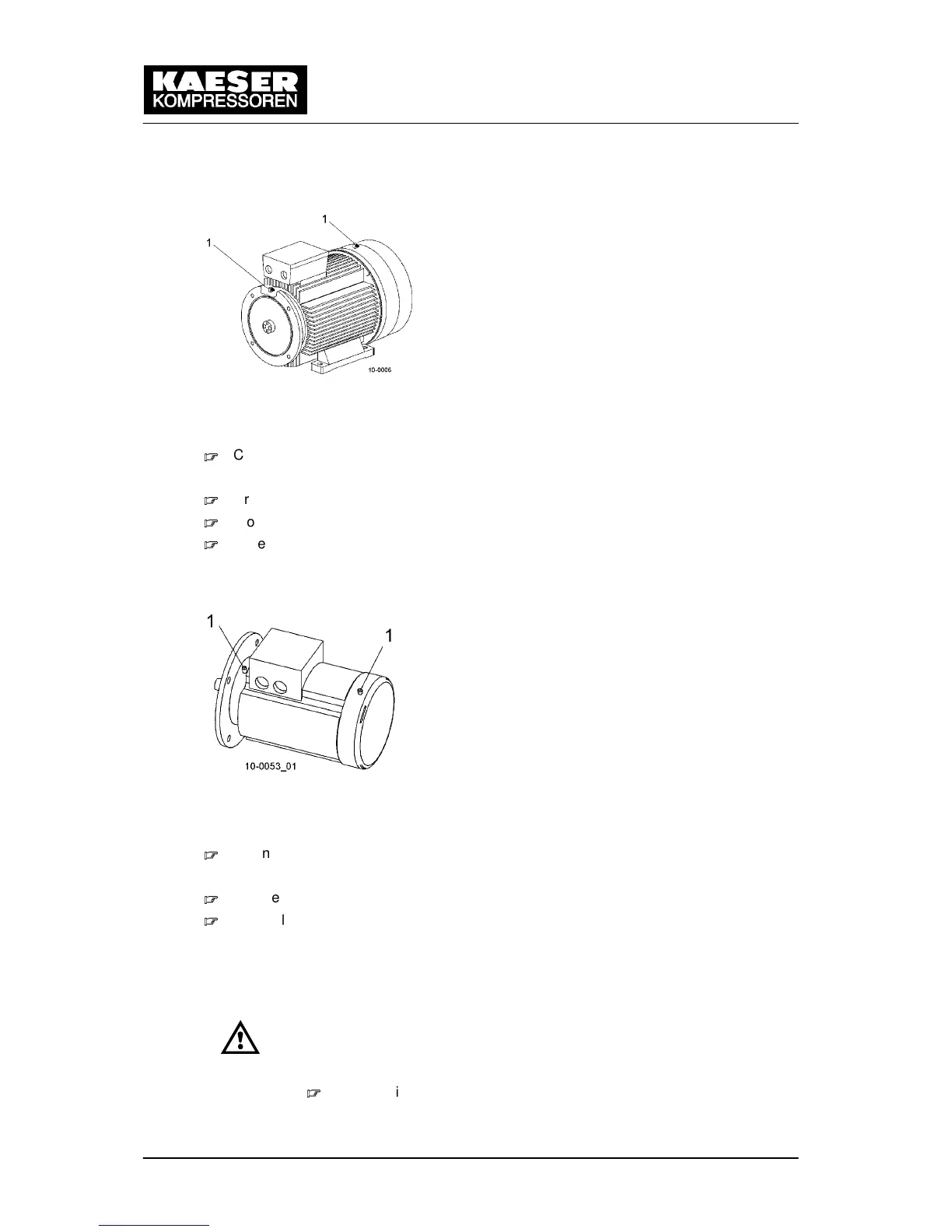

Compressor motor

The motor bearings are fitted with grease nipples.

Fig. 24 Compressor motor maintenance

1 Grease nipple

Clean the grease nipple (1) with a rag.

Apply the quantity of grease as stated on the motor nameplate.

Grease both bearings with a grease gun.

Close all access doors; replace and secure all removable panels.

Reset the maintenance interval counter.

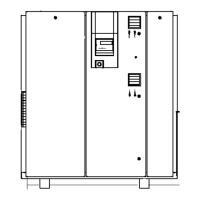

Fan motor with grease nipple

The fan motor is equipped with grease nipples for re---greasing the bearings.

Fig. 25 Fan motor maintenance

1 Grease nipple

Clean the grease nipple (1) with a rag.

See chapter 2.7.2 for the required grease volume.

Grease both bearings with a grease gun.

Close all access doors; replace and secure all removable panels.

Fan motor without grease nipple

Fan motor bearings are permanently greased and need no further greasing.

10.8 Checking the Coupling

Danger of injury from rotating coupling!

Severe injury could result from touching the coupling while it is rotating.

Never switch the machine on without the guard in place over the

coupling.

WARNING

Loading...

Loading...