IEEE-488 PROGRAMMING

Examples:

For a delay of 0.0029x send WZX.

For a delay of 30.05s~ send W3005OX.

For a delay of 60s~ send W6OCCOX.

Upon power up or after receiving a DCL or SDC &ni-

mand, the instrument will rehxn to the default condition.

Programming Example-To program a 250msec delay

period into the instrument, enter the following statements

into the computer:

The instrument will wait for 250msec after each triggered

conversion before executing the next conversion period.

3.9.19 Self-Test (J)

The J command causes the instrument to perform tests it

automatically performs upon power up. When the self-test

command is given, the Model 199 performs the following

tests:

1. ROM Test

2. RAM Test

3. EY’ROM Test

J command parameters include:

JO = Perform self-test.

Jf the self-test is successful, the J byte in the UO status word

will be set to 1. If E’PROM fails, the message “UNCAII’

will be displayed and the J byte in the Ul status word will

be set to 2. An EY’ROM failure is also flagged in the Ul

status word. If ROM and RAM fails, the instrument will

lock up.

See paragraph 67.2 for more information on these tests

and recommendations to resolve a failure.

Prog~ng Example-Enter the following statements in-

to the computer to perform the Model 199 self-test:

When the END LINE key is pressed the second time, the

instrument performs the self-test. If successful, the self-

test byte (J) in the UO status word will be set to 1.

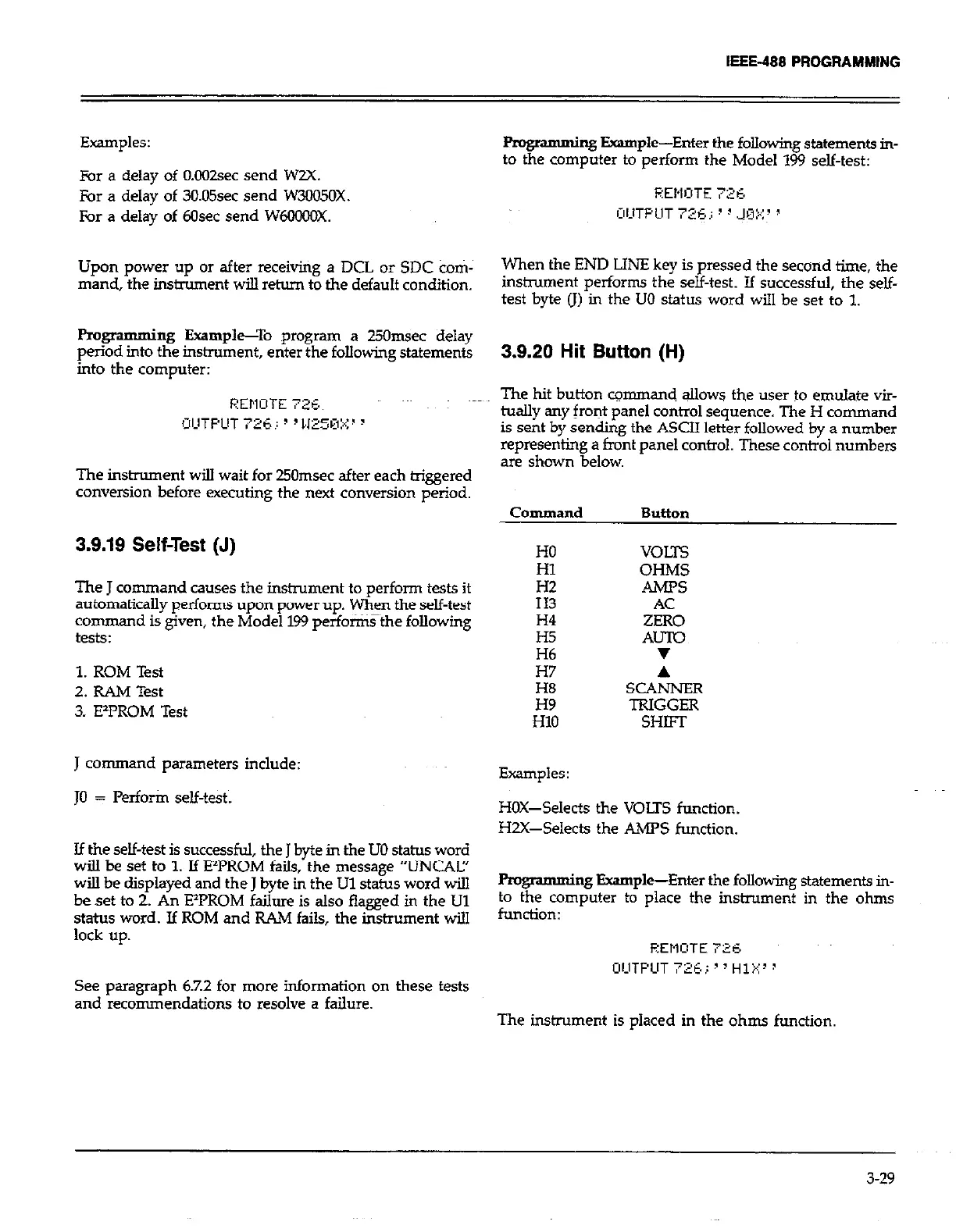

3.9.20 Hit Button (H)

The hit button command allows the user to emulate vir-

tually any front panel control sequence. The H command

is sent by sending the ASCII letter followed by a number

representing a front panel control. These control numbers

are shown below.

Command

HO

Hl

E

H4

H5

ii;

E

HlO

Button

VOLTS

OHMS

AMPS

ZEO

AUTO

7

SCA&ER

TRIGGER

SHIET

Examples:

HOX-Selects the VOLTS function.

H2X-Selects the AMPS function.

F’qmmmirtg Example-Enter the following statements in-

to the computer to place the instrument in the ohms

function:

The instrument is placed in the ohms function.

3-29

Loading...

Loading...