KIC 2000 v2.4.0.x

KIC 2000 User Manual 57

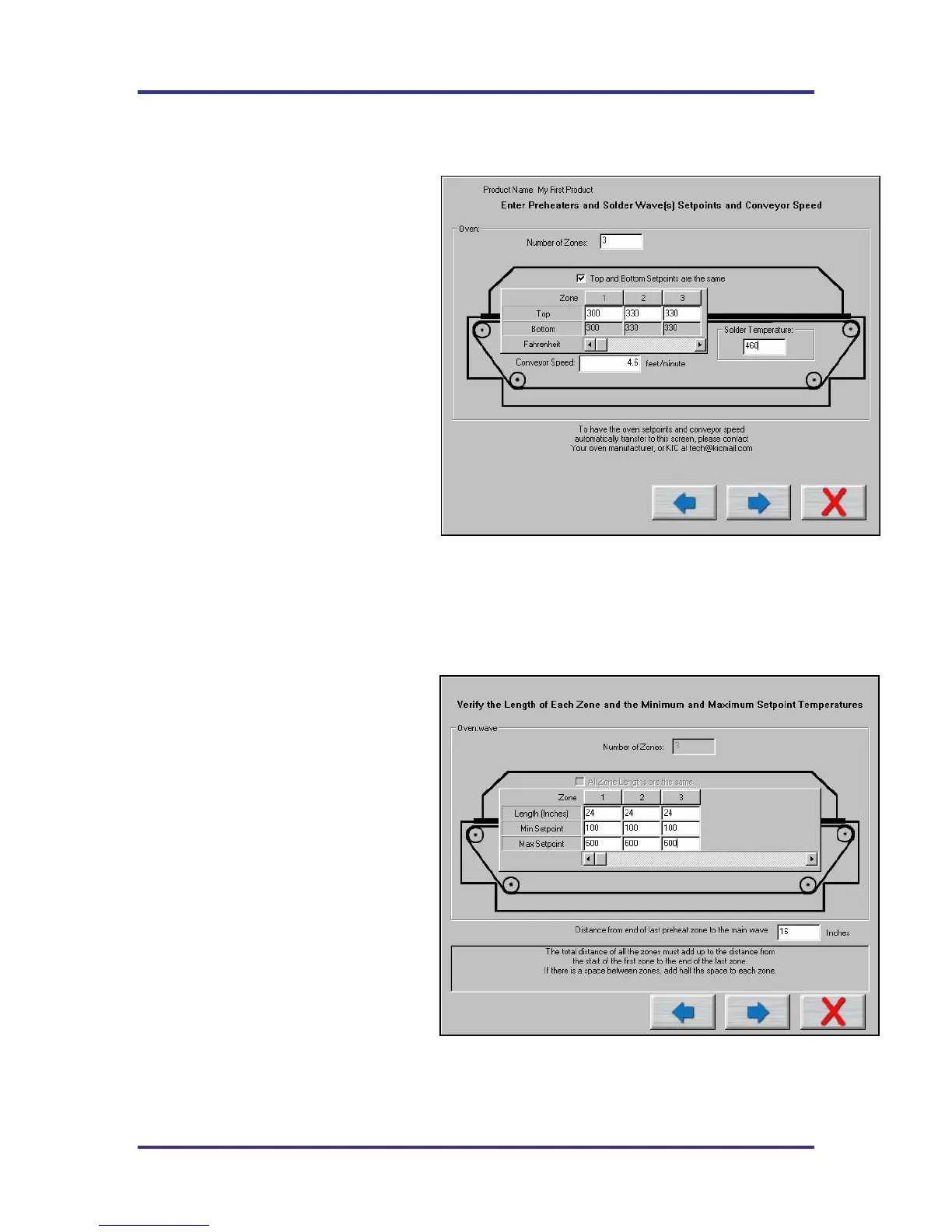

Entering Temperature Set Points and Conveyor Speed

If you typed a new oven name, the KIC 2000 software requires you to enter the number of heated zones or

pre-heat zones in your wave solder machine.

See Figure 87.

If your process requires different top and

bottom set points, deselect the check box

labeled Top and Bottom set points are the

same This will allow the user to enter

different values for top and bottom heaters in

each zone. If your oven has top and bottom

heaters, but not in all of the heated zones,

just enter the same value as the actual set

point in that zone for both the top and

bottom setting.

This is also were you will enter the

temperature settings for each zone or pre-

heater in your wave solder machine and the

conveyor speed setting. In the field marked

Solder temperature enter the setting for the

solder pot temperature from your wave

solder machine.

When you have finished entering this

information select the Forward Arrow button

to continue.

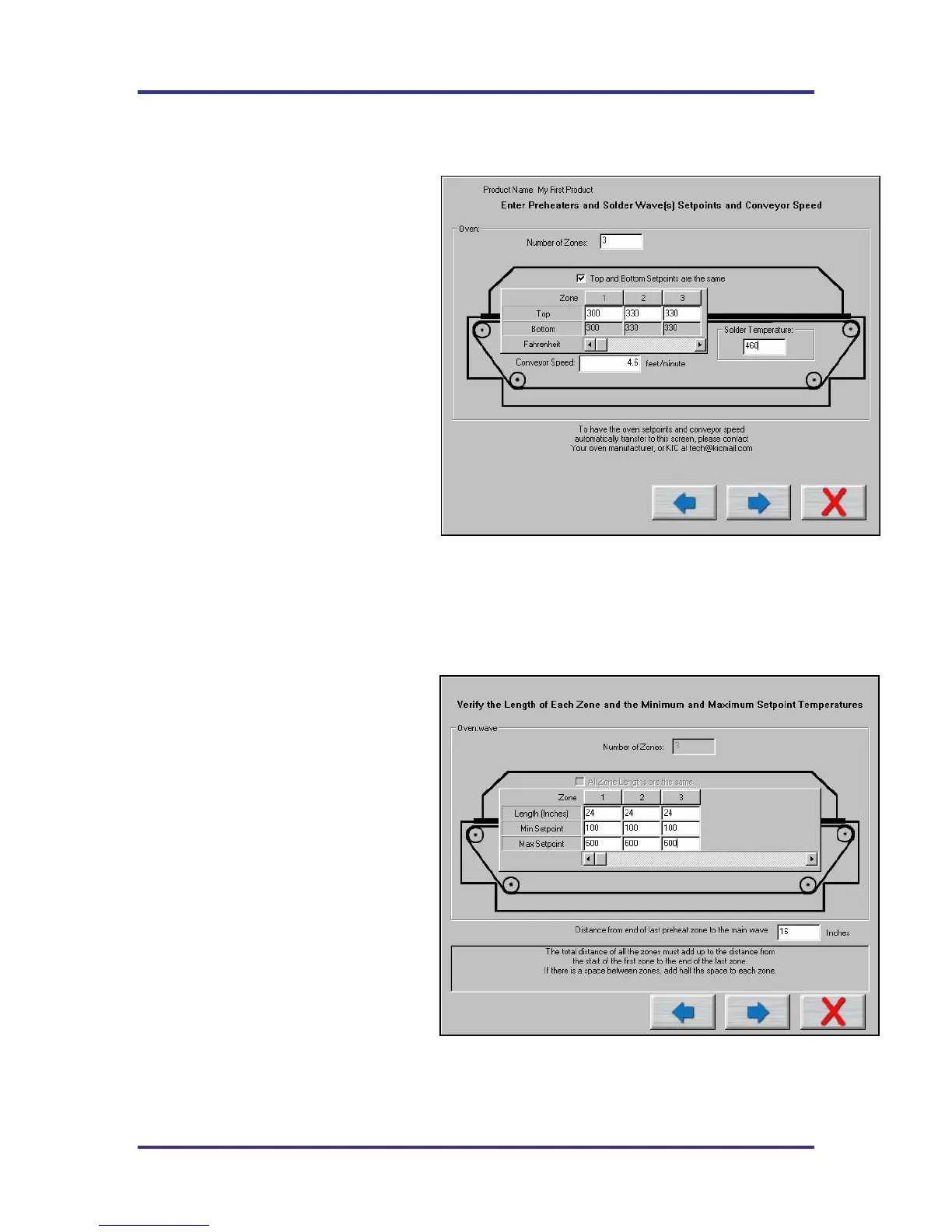

Zone length, Minimum and Maximum Temperature settings

If you typed a new oven name, the KIC 2000

software also requires you to enter the length

of each zone as well as the minimum and

maximum zone temperature settings. This

information will help the KIC 2000 software

narrow the possibilities of prediction results

that your oven can actually achieve. See

Figure 88.

For wave solder processes you are required

to enter the distance from the end of the last

preheat zone to the beginning of the main

wave. Enter this value in the field labeled

Distance from end of last preheat zone to the

main wave.

Once you have finished entering this

information select the Forward Arrow

button to continue.

Figure 87: Run a Profile Screen #2

Figure 88: Run a Profile Screen #3

Loading...

Loading...