KIC 2000 v2.4.0.x

58 KIC 2000 User Manual

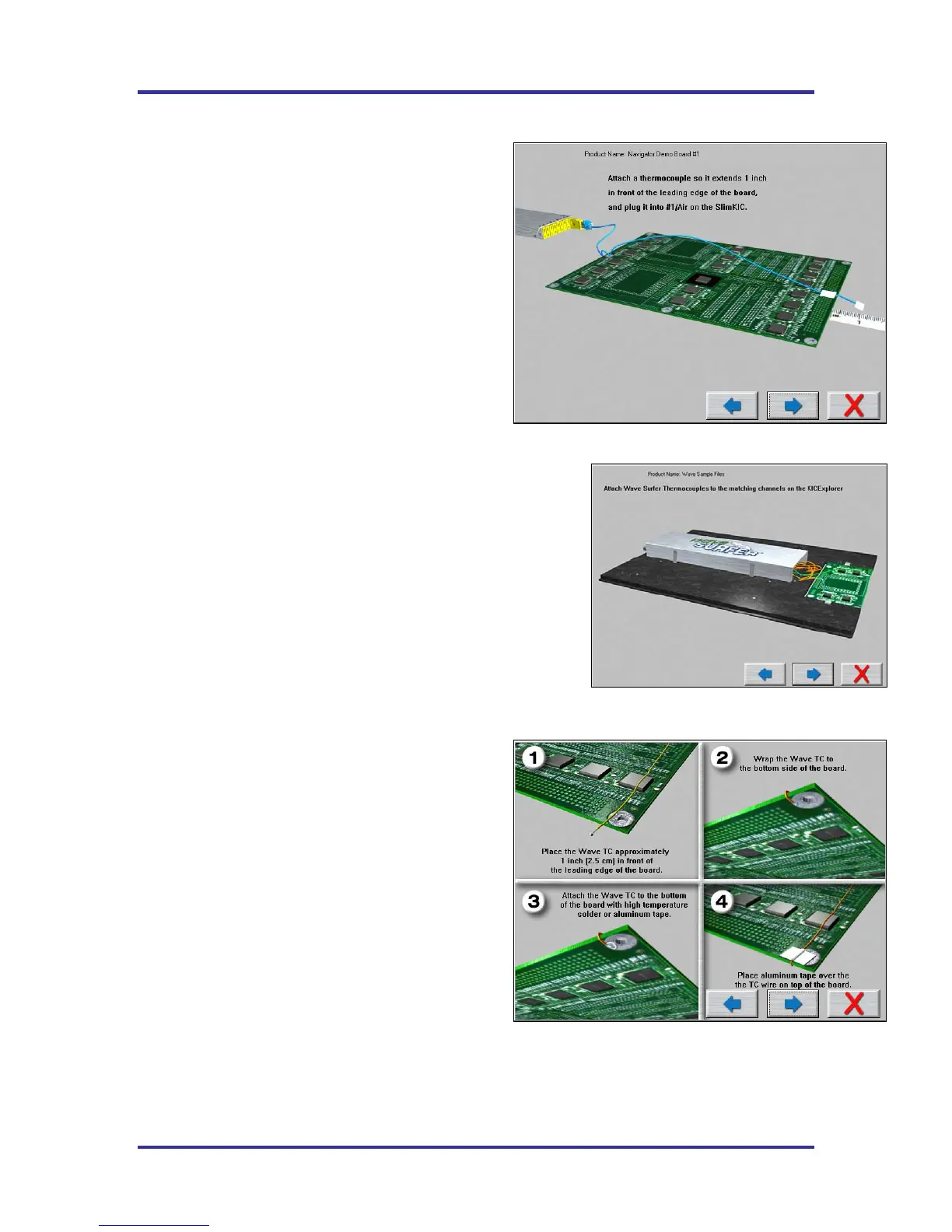

Connecting the Air TC

The next screen shows directions for attaching the Air

TC to your product. It is important to follow these

instructions. See Figure 89.

The Air TC starts and stops the profile automatically,

measures the oven, and provides useful profile

information.

In certain processes it may be beneficial to wrap the end

of the Air TC with tape to give it more surface area.

KIC recommends wrapping the Air TC when profiling:

• Wave Solder.

• Anytime IR heat is present.

Wave Surfer

Wave Surfer users connect the designated

thermocouples to the corresponding channels on the

SlimKIC 2000.

Make sure the retainers holding the SlimKIC 2000 are

in place and secure. See Figure 90.

If any of the embedded thermocouples are damaged or show signs of

wear replace them.

In addition to the instructions given, it is very important that you

position the “Air TC” so that it touches the wave(s). The “Air TC

must pass through the wave in order to provide accurate profile

results. Of course it you are profiling a Wave Solder machine with

the wave off, the Air TC position is not critical to the profile results.

Select the Forward Arrow button to continue.

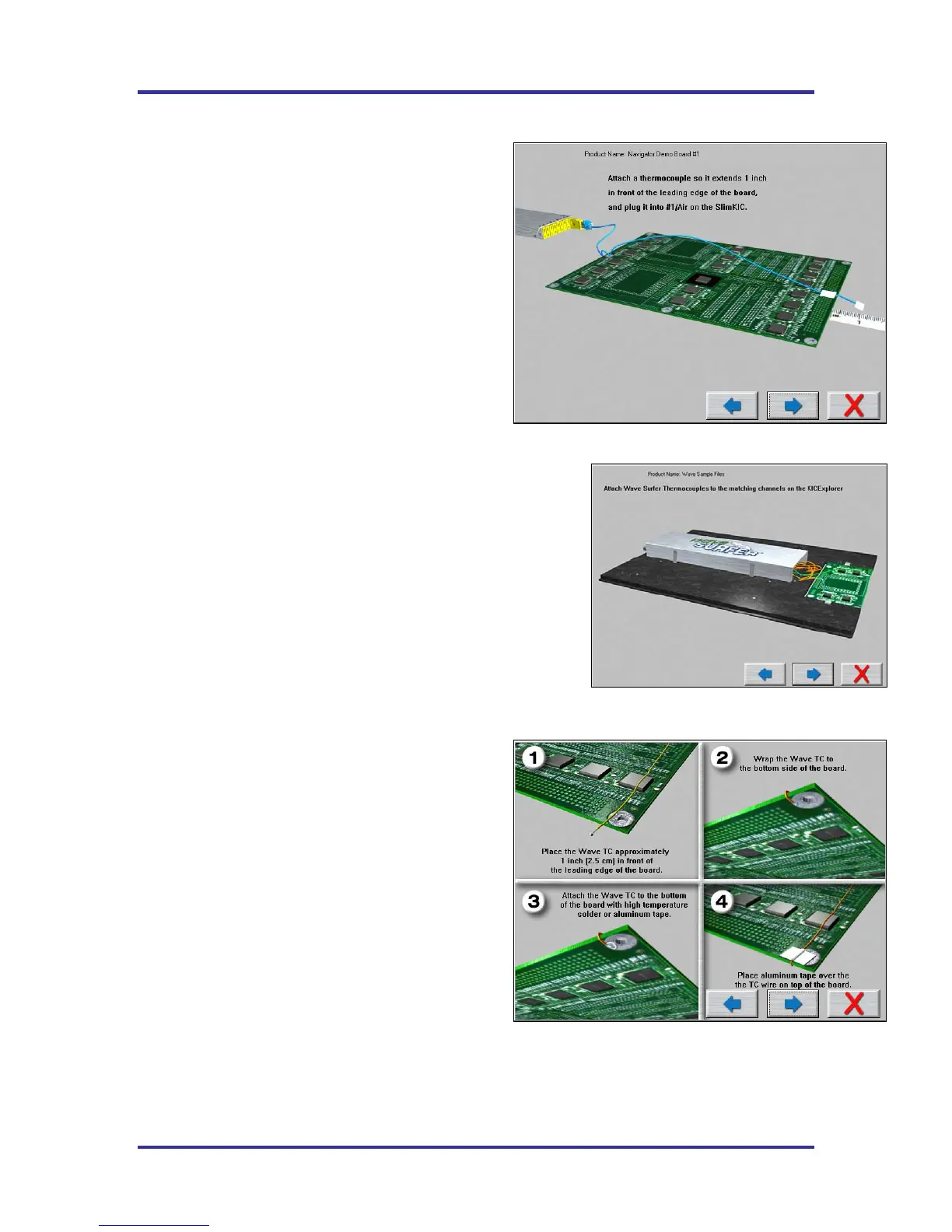

Connecting Wave TC’s

The next screen will depict thermocouple attachment for

wave solder profiling with the wave on. The KIC 2000

software utilizes two Wave TC’s in addition to the Air

TC to collect wave specific data. See Figure 91.

One Wave TC is placed on the Right side of the board

and one on the Left side near the leading edge of the

profile board.

KIC recommend using high temperature solder to

connect both Wave TC’s.

The wave TC’s will measure -Wave Dwell time and

Parallelism when profiling a wave solder machine with

the wave on.

Select the Forward Arrow button to continue.

Figure 89: Run a Profile Screen #4 – No Wave Surfer

Figure 90: Run a Profile Screen #4 – Wave Surfer

Figure 91: Run a Profile Screen #5

Loading...

Loading...