7-18 September 2004

Argonite

®

Engineered Fire Suppression System

38-KFSARG-000

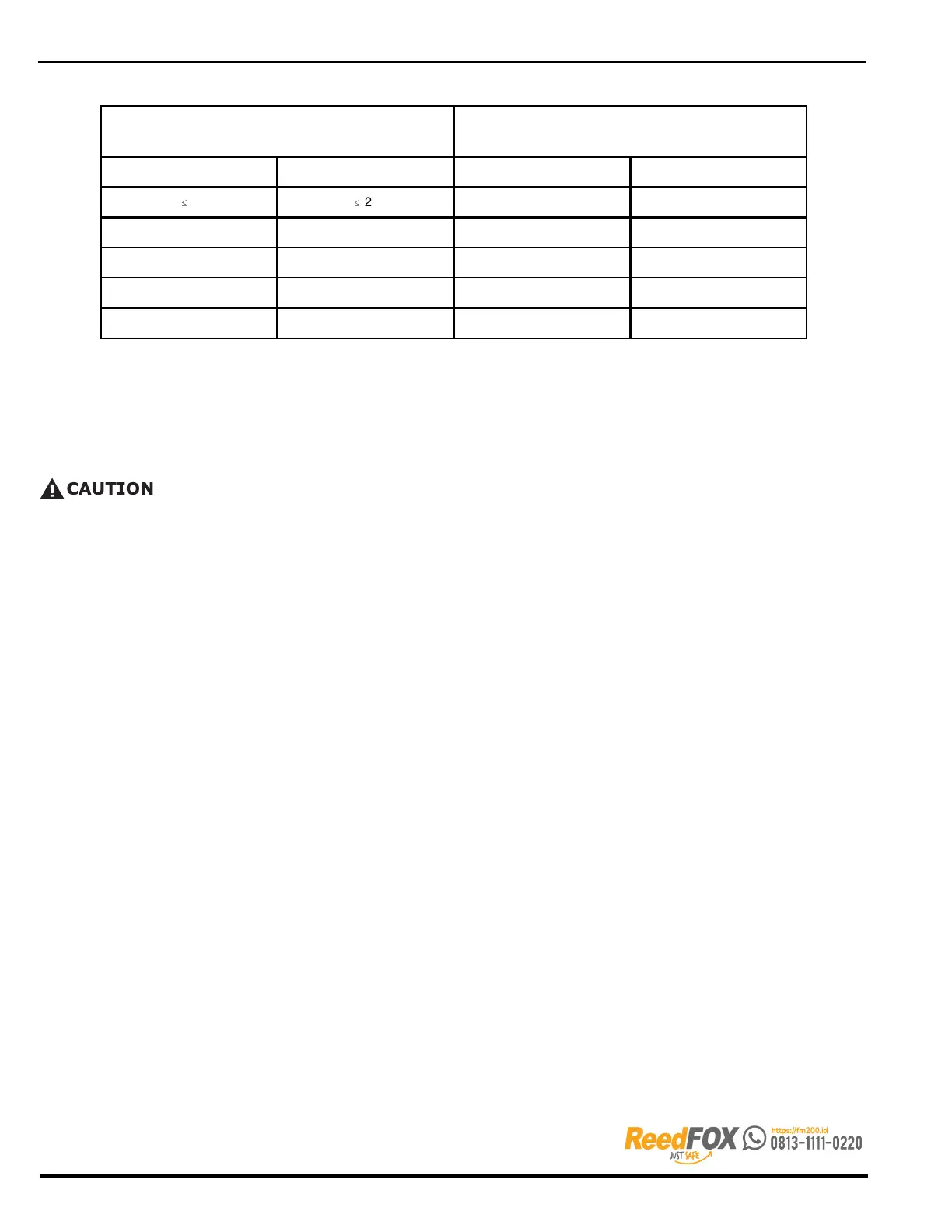

Table 7-11. Rod Size As Determined by Pipe Size for Fire Protection

Pipe Size Rod Size

in. mm in. mm

1

25

3/8 9.6

1½ to 3 40 to 80 1/2 12.7

4 and 5 100 and 125 5/8 15.8

6 150 3/4 19.0

8 200 7/8 22.2

7-16 CLEANING OF PIPE NETWORK

Each pipe section shall be cleaned internally after preparation and before assembly by

means of swabbing, utilizing a suitable nonflammable cleaner. The pipe network shall be

free of particulate matter and oil residue before installation of nozzles or discharge devices.

7-17 PRESSURE TESTING OF PIPE NETWORK

Never include actuation valves (cylinder or selector) as part of the piping

network pressure test. As outlined in Paragraph 6-5, always disconnect

the cylinder outlet hose from the manifold check valve and cap all check

valves (using cap P/N 38-509865-001) prior to pressure testing of the

piping network. For single cylinder systems, ensure the piping is plugged

and the outlet hose detached before pressure testing.

Pneumatic pressure testing creates a potential risk of injury to personnel in

the area as a result of airborne projectiles if rupture of the piping system

occurs. Prior to the pneumatic pressure test being conducted, the protected

area shall be evacuated and appropriate safeguards shall be provided for

test personnel.

NFPA 2001

The piping shall be pneumatically tested in a closed circuit for a period of 10 minutes

at 40 PSIG (276 kPa) per NFPA 2001. At the end of 10 minutes, the pressure drop

shall not exceed 20 percent of the test pressure. Exception: It shall be permissible

to omit the pressure test if the total piping contains no more than one change in

direction fitting between the storage container and the discharge nozzle, and if all

piping is physically checked for tightness.

ISO 14520-1

Pneumatically tested at 45 PSI (3 bar) for a period of 10 minutes using Air/Argonite

or N

2

. Pressure drop not to exceed 20% of the test pressure at end of test.

Note: A test report/statement of completion must be issued.

Loading...

Loading...