TP-5606 6/02 Scheduled Maintenance 3-3

Lubrication System

Oil Selection

The selection of engine oil is very important to a diesel

engine. If an unsuitable oil is used or an oil change is

neglected, damage and a shorter engine life may result.

Oil must meet the American Petroleum Institute (API)

classification of CC or CD. Avoid mixing different brands

of oils and lubricants; oils of different manufacturers may

be incompatible and deteriorate when mixed.

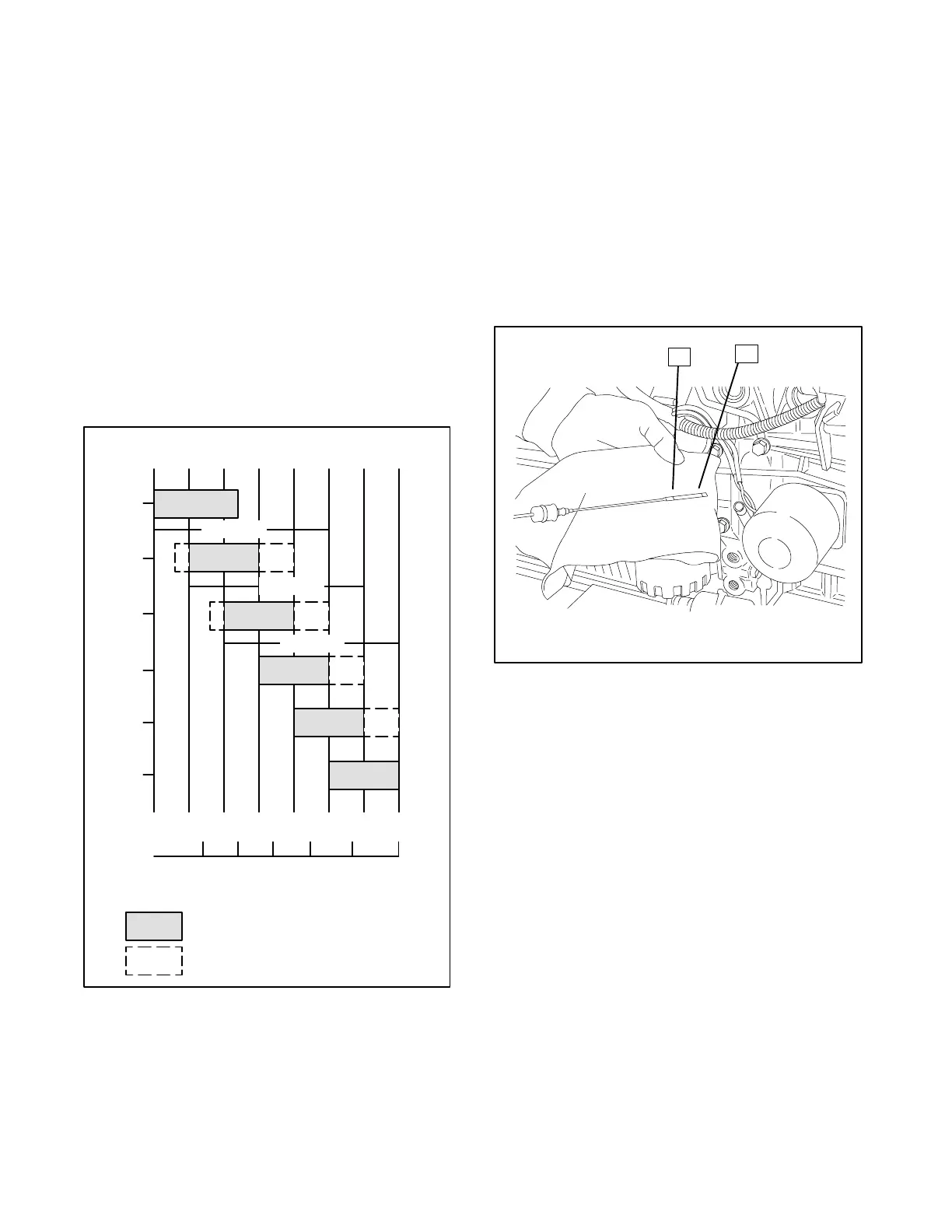

Recommended SAE viscosity designations for given

temperature ranges in which the generator set will be

operated are listed in Figure 3-1.

NOTE

Failure to observe these standards may cause

inadequate oil pressure and cold-starting difficulties.

S.A.E. Service

Grade

°C

°F

--30 --20 --10 0 10 20 30 40

0 20 40 60 80 100

Operating Temperature

Recommended Value

Usable Limit

5W

10W

20W

SAE 20

SAE 30

SAE 40

°C

°F

5W

10W

20W

20

30

40

5W20

10W30

20W40

Figure 3-1. Engine Oil Selection

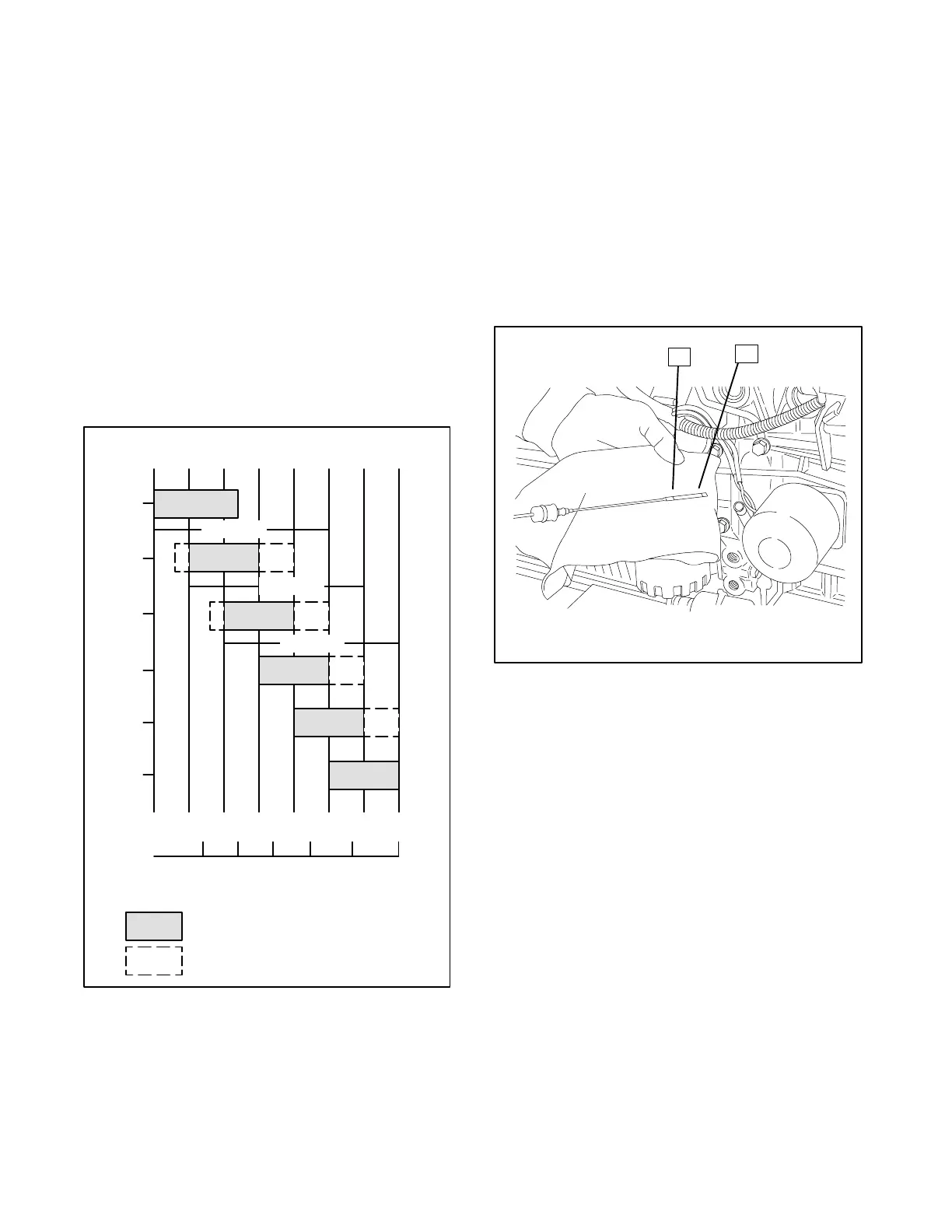

Oil Check

Check crankcase oil level daily or before each start to

insure that the level is in the safe range. To check oil

level, remove oil dipstick and wipe dipstick clean (see

Figure 3-2). Reposition dipstick in crankcase and push it

all the way down into the tube. Remove dipstick and

check the level. Oil level should read between MIN and

MAX marks on dipstick. Do not operate set if oil level

exceeds the MAX mark or registers below the MIN mark

on dipstick.

1-933

1. MAX Level 2. MIN Level

1

2

Figure 3-2. Oil Level Check

NOTE

Do not check oil level when the set is in operation. The

engine must be stopped and on a level surface when

checking oil. Most accurate oil reading is obtained by

shutting down the generator and waiting several

minutes before checking oil.

Loading...

Loading...