Maintenance

Lubricants and operating fluids

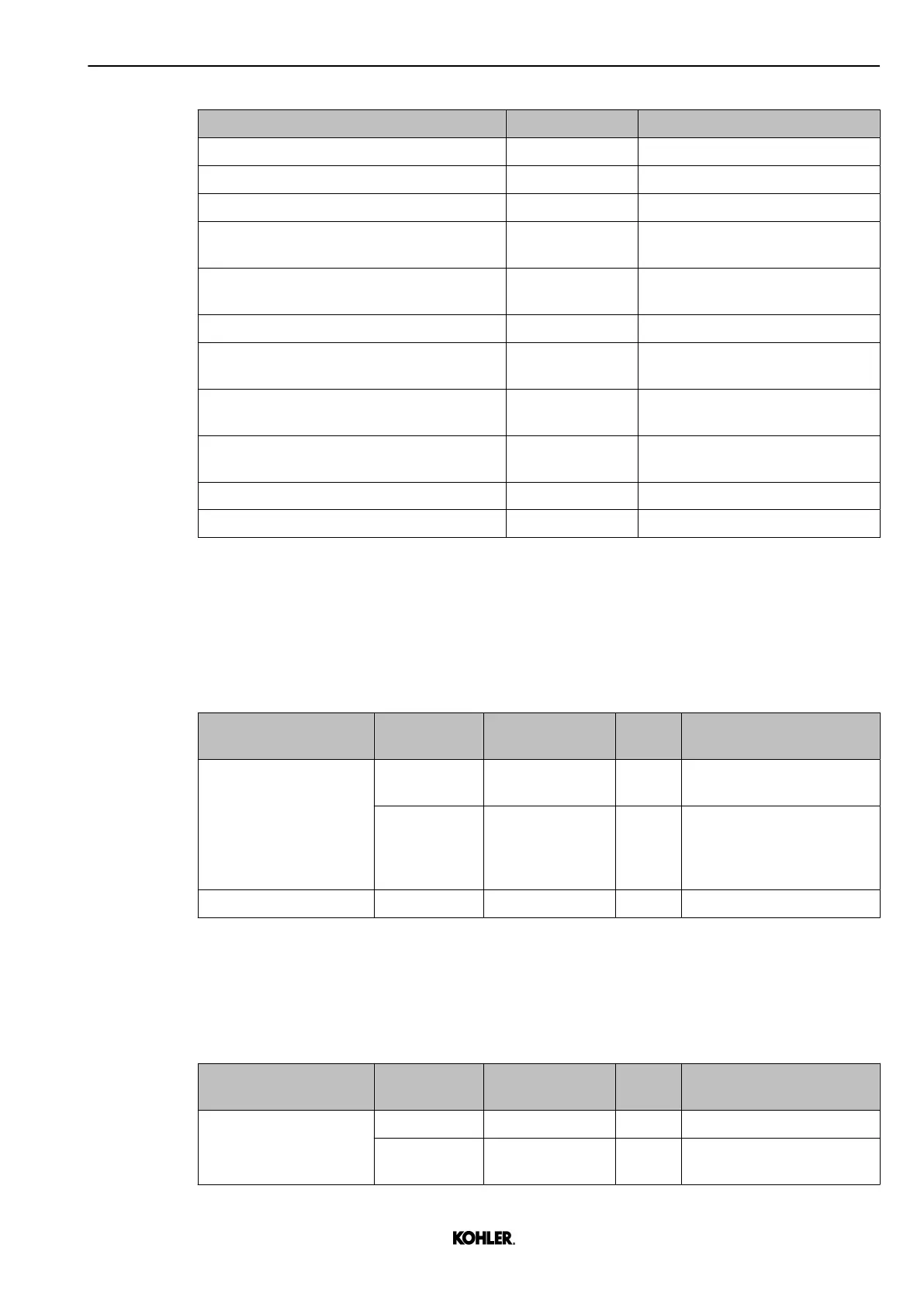

Parameter Unit Method

Nitrate / Nitrite - EN 12014

pH value - EN/ISO 10523 ASTM D1287

Glycol % DIN 51375

Pour point °C

°F

ISO 3016 ASTM D5985

Freezing point °C

°F

ISO 3013 ASTM D1177

Bacteria count -

Additive elements

(B, Ba, Ca, K, Mg, Na, P, S, Si)

mg/kg

ppm

DIN 51399

Wear elements

(Al, Cr, Cu, Fe, Mg, Mo, Ni, Pb, Sn, Ti, V)

mg/kg

ppm

DIN 51399

Contamination

(Ca, Mg, Mo, Si, Sn, Zn)

mg/kg

ppm

DIN 51399

Corrosion copper - EN/ISO 2160

Corrosion steel - ISO 7120

Tab. 39: KD coolant analysis parameters

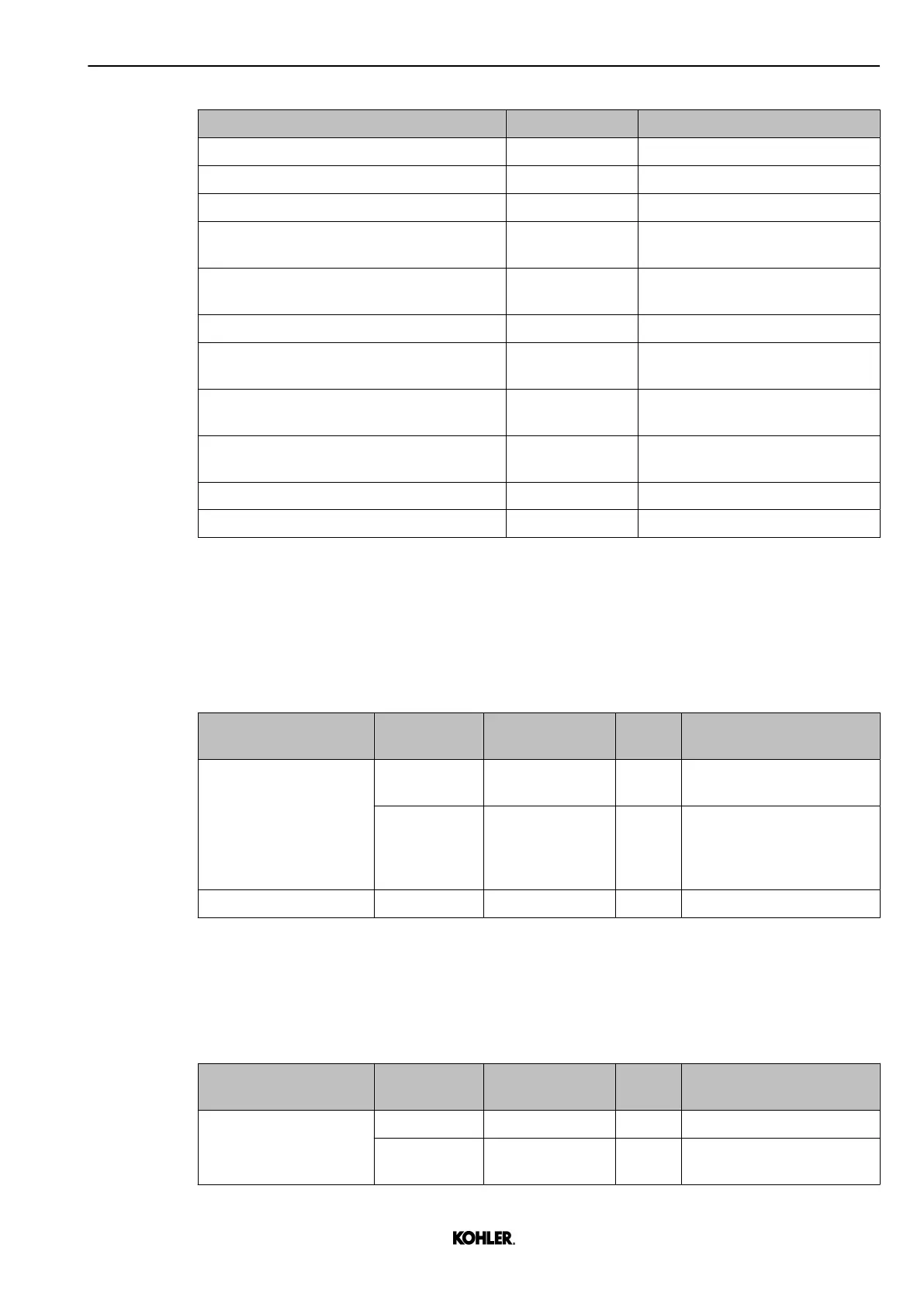

Keeping the cooling system clean

Usually, cleaning the cooling system is not necessary.

In case of contamination with bacteria, fungi or yeast, a mixture of fresh coolant added with

biocides is suitable. The following products are approved:

Manufacturer

Product-

name

Concentration Packin

g

Order #

Schülke & Mayr Gmbh Grotan WS

Plus

0.15% by volume Liquid X00065326

(10 kg (22.05 lb))

Grotanol SR1 1% by volume Liquid X00057297

(10 kg (22.05 lb))

X00057298

(200 kg (441 lb))

Troy chemical company Troyshield 1% by volume Liquid -

Tab. 40: KD cooling system cleaners

If there is need for a full cleaning of the system, flush the entire system with adequate water,

then:

– Use the approved products to clean the system (see: tab. 41, page 155).

– Use the approved products to clean the components (see: tab. 42, page 156).

Manufacturer

Product-

name

Concentration Packin

g

Order #

Kluthe Hakutex 111 2% by volume Liquid X00065751

Hakupur

50-706-3

2% by volume Liquid X00055629

KD62V12 33521030301_8_1 EN_US 2022-09

© 2022 by Kohler Co. All rights reserved.

155

Loading...

Loading...