Do you have a question about the Kohler MAGNUM M18 and is the answer not in the manual?

Details on how to identify engines by model, spec, and serial numbers for proper part ordering.

Guidance on selecting the correct type and viscosity of oil for engine lubrication.

Comprehensive list of technical specifications, tolerances, and torque values for engine components.

Reference table for standard torque values for bolts, screws, nuts, and fasteners.

Details on a quality tool kit designed for efficient disassembly, repair, and reassembly procedures.

Listing and application of specialized tools for valve service operations.

Description of an engine analysis kit with instruments for measuring critical performance items.

Instructions for constructing and using a simple tester for the engine's electronic ignition module.

Information on a cylinder leakdown tester, an alternative to compression tests for diagnosing leaks.

Table outlining required maintenance tasks and their recommended service frequencies.

Procedure for changing engine oil for new, overhauled, or rebuilt engines.

Instructions for servicing the engine's high-density paper air cleaner element.

Procedure for inspecting, gapping, and replacing spark plugs every 100 operating hours.

Procedure for preparing the engine for storage for approximately two months or more.

Common causes and solutions for engines that crank but fail to start.

Common causes and solutions for engines that start with difficulty.

Identifies causes and solutions for engine overheating issues.

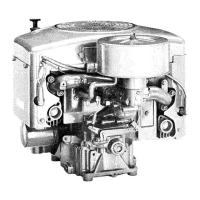

Guide to inspecting the engine's external appearance and condition before disassembly.

Procedure for performing a cylinder leakdown test to diagnose valve or ring leaks.

Instructions for the disassembly and reassembly of the square style air cleaner.

Instructions for the disassembly and reassembly of the dome style air cleaner assembly.

Details on the anti-icing air cleaner assembly and its installation procedures.

Procedures for inspecting and replacing the paper air cleaner element.

Guide to inspecting critical components of the air cleaner assembly for damage or wear.

Explanation of the typical fuel system components and how fuel flows through the system.

Detailed steps for adjusting the fuel mixture and idle speed on Kohler carburetors.

Description of the centrifugal flyweight governor's function in maintaining constant engine speed.

Procedures for adjusting governor settings for initial setup, high speed, and sensitivity.

Covers adjustment, disassembly, cleaning, inspection, repair, and reassembly of Walbro carburetors.

Step-by-step guide for adjusting main fuel and idle fuel needles on Walbro carburetors.

Information on operating with fixed main carburetors at high altitudes and necessary adjustments.

Explanation of the full-pressure lubrication system and its components.

Details on the full-flow oil filter, its function, and replacement.

Information on the optional Oil Sentry system for monitoring oil pressure and engine shutdown.

Overview of the electronic magneto ignition system, its components, and operation.

Guide to diagnosing and correcting ignition system-related starting problems.

Procedure for inspecting, gapping, and replacing spark plugs every 100 operating hours.

Guidelines for regular battery maintenance to ensure proper charging and performance.

Details on the Bendix drive electric starter, its operation, and service procedures.

A suggested sequence of steps for complete engine disassembly.

Initial steps for engine disassembly: disconnecting leads and draining fluids.

Procedure for removing the intake manifold and carburetor assembly.

Steps for removing the grass screen, flywheel, and fan from the engine.

Procedure for separating the crankcase halves for internal component access.

Instructions for inspecting the flywheel for cracks, keyway damage, and ring gear condition.

Guide to inspecting cylinder heads for carbon deposits, flatness, and potential damage.

Procedures for inspecting cylinder barrels for scoring and reconditioning via honing.

Guidance on inspecting valve components for wear, damage, and potential causes of engine issues.

Information on identifying style D pistons and matching piston rings used in Magnum engines.

Procedures for inspecting camshaft and crankshaft gear teeth, bearings, and keyways.

A suggested sequence of steps for complete engine reassembly.

Procedure for installing connecting rods to the crankshaft, including orientation notes.

Steps for installing crankshaft bearings and the crankshaft assembly into the crankcase.

Procedure for lubricating and installing tappets and the camshaft into the crankcase.

Instructions for installing cylinder heads, gaskets, and spark plugs with proper torque.

Procedure for installing the fan, flywheel, and grass screen with safety precautions.

Final checks before operating the engine, including hardware tightness and fluid levels.

Recommended procedures for testing the engine on a test stand before installation.

| Compression Ratio | 8.5:1 |

|---|---|

| Fuel System | Carburetor |

| Horsepower | 18 HP |

| Displacement | 677 cc |

| Cooling System | Air-cooled |

| Oil Capacity | 1.9 L |

| Starter | Electric |

| Alternator | 15 Amp Regulated |