Fill block for Configuration 1

or 2, showing attachment

point for fill hose, safety

valve, MPV, and Auto Shut-

Off sensor

2.5. Pneumatic Air Flow

The compressor has two elements where moisture and / or condensate is removed.

2.5.1. Intermediate Stage Condensate Collector and Drain.

A condensate drain is positioned after the first stage intercooler, prior to the intake for

the second stage.

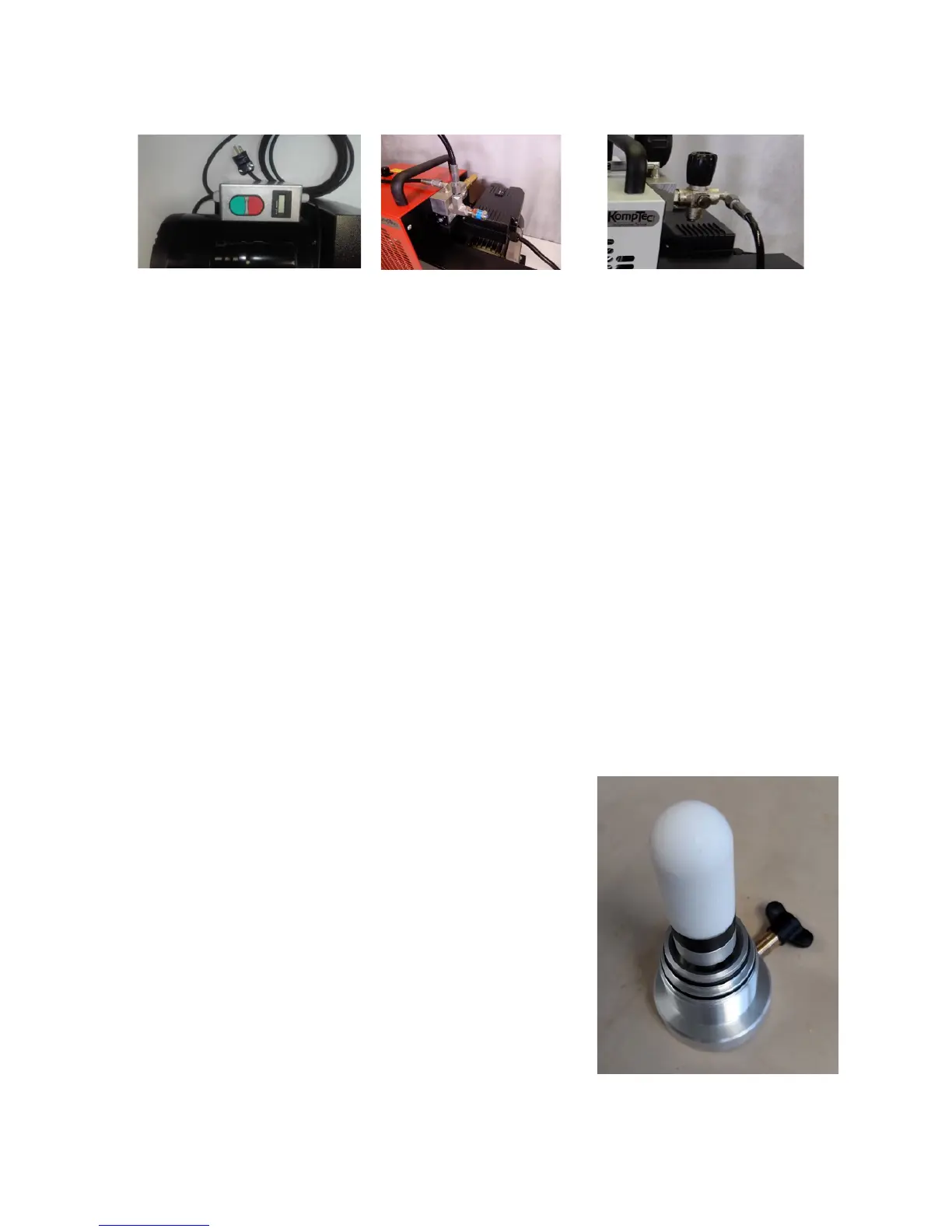

2.5.2. Final Condensate Collector, Drain and Filter.

The filter housing contains both the Final Condensate Collector as well as the air filter.

One key element used in the condensate collector is the sintered filter. A conical syn-

thetic sintered filter is installed in the base of the filter housing. Air enters the housing

after the 3

rd

stage and the aftercooler, and flows through the sintered filter where oil and

moisture condense on the interior surface of the sintered filter, and fall to the base of the

condensate collector. The moisture and oil that is captured here are contaminants that

need not be captured by the filter, extending its effective service life.

An additional benefit of using the sintered filter

prior to the filter cartridge is that the air that exits

the sintered filter and flows thru the molecular sieve

filter has an even velocity across the surface of the

filter as it enters the filter. This avoids the creation

of a high velocity path thru the filter material. Con-

stant air velocity permits optimum effectiveness of

and utilization of the molecular sieve material

Loading...

Loading...