KT-70E / KT-90E / KT-70SE User Manual Page 37 of 59 24 April 2018

9. Troubleshooting

To avoid damage to property or life-threatening injuries during the removal of faults

on the compressor, the following points must be observed:

- Eliminate the fault only if you also have the specified qualifications.

- Protect the compressor against accidental restart by pulling the power plug.

Also read the chapter "General safety instructions".

9.1. Tabular overview of possible malfunctions and suggestions to help eliminate the fault.

If faults occur during operation of the compressor, check for possible causes using the

following table If the fault can not be resolved by one of the measures listed, please

notify a service technician or the manufacturer.

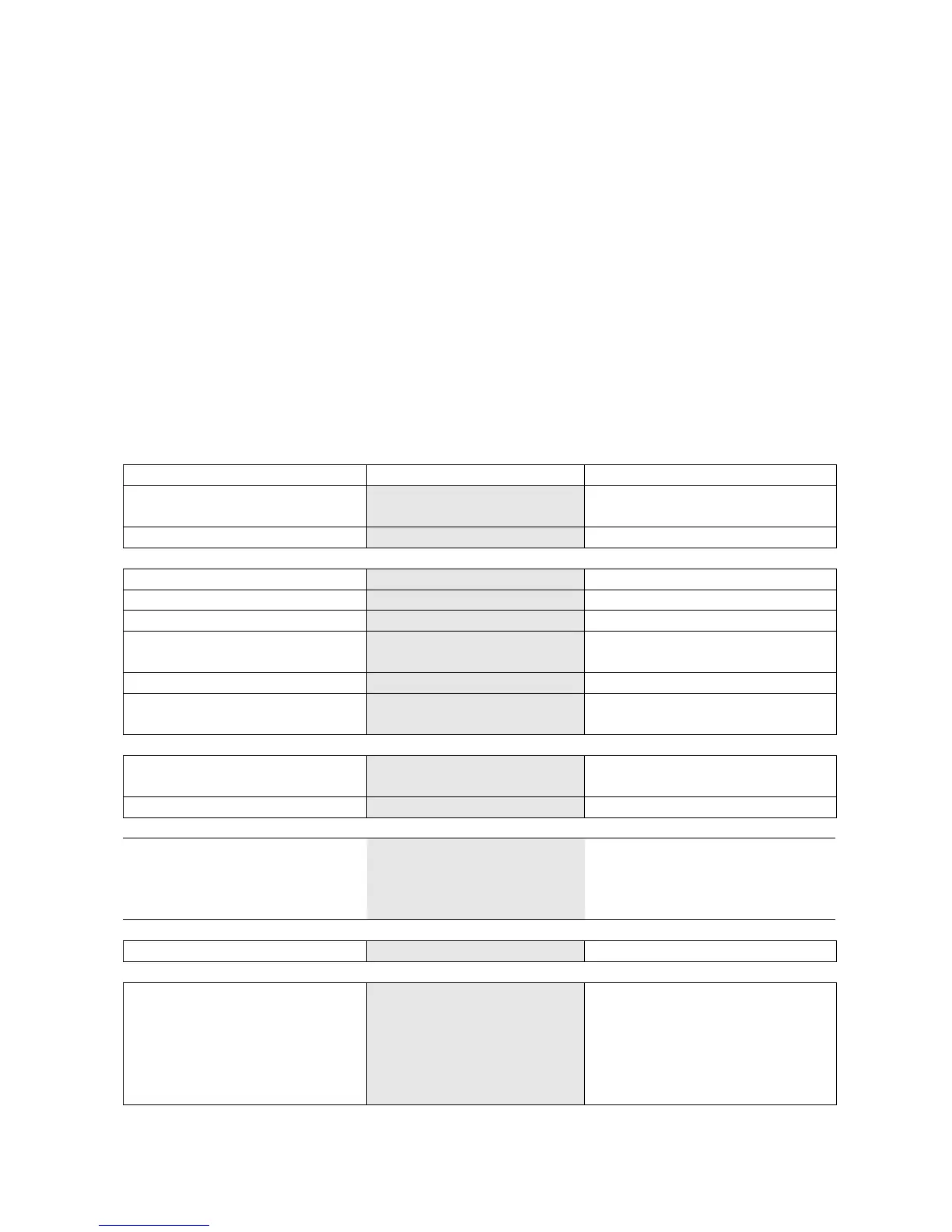

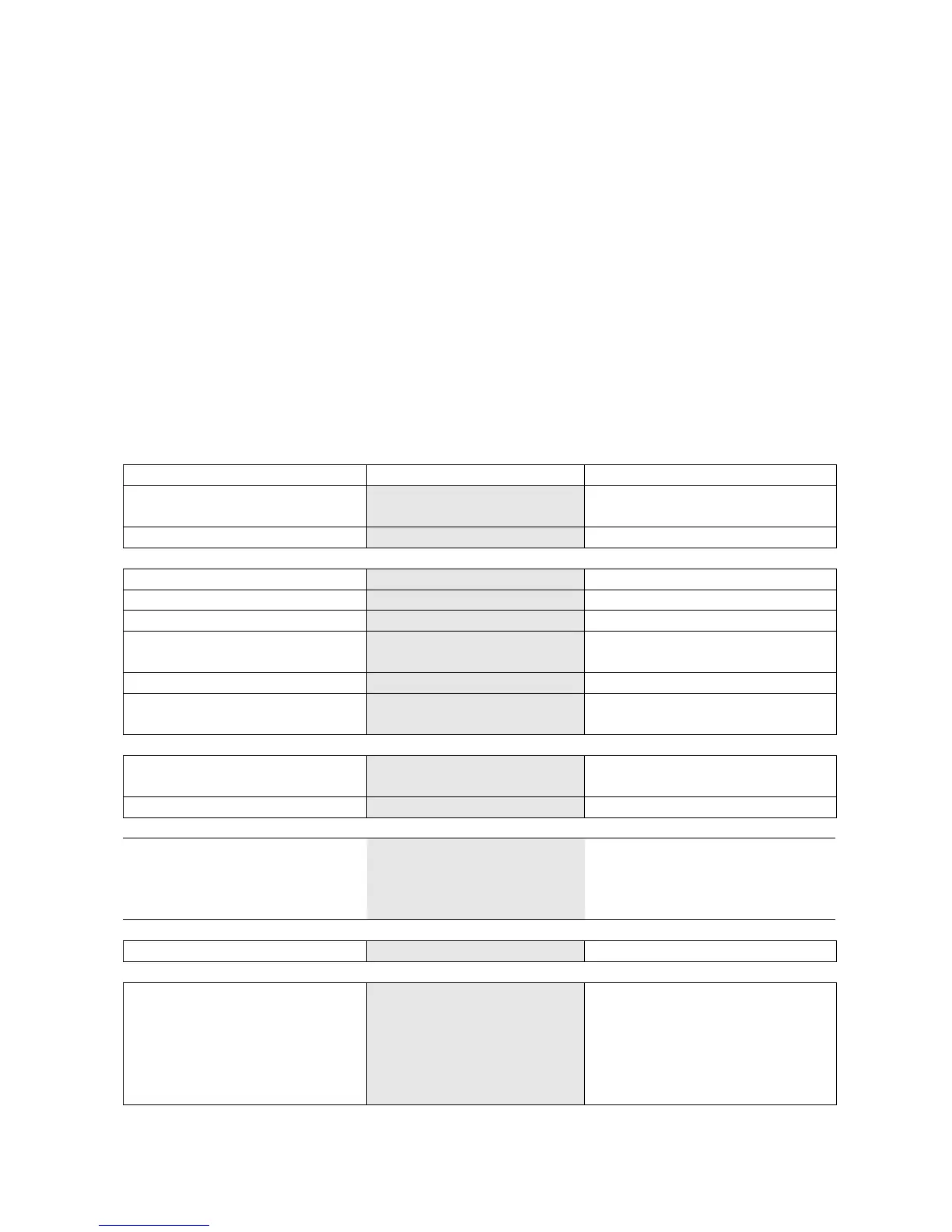

9.1.1. List of Faults

Compressor does not reach pres-

sure

Leaking pipe or condensate

drain

1

st

stage inlet valve does not

seal

Faulty o-ring on female

Quick Disconnect

Replace with 010-70 o-ring

1

st

or 2

nd

stage overpressure

valves release air

Pressure between stages is

too high

Check inlet valve of follow-on

stage

Condensate oil leaking onto base

plate

Residual pressure in filter af-

ter motor is off forcing resid-

ual condensate out of pres-

sure relief valves

Bleed residual pressure in com-

pressor to zero after completing

operation

Final pressure valve releases air

Compressor does not start

Excess residual pressure in

the compressor

Open intermediate and final con-

densate drains to reduce back pres-

sure on motor before starting mo-

tor. Verify gasket on intermediate

drain screw did not create block-

age.

Loading...

Loading...