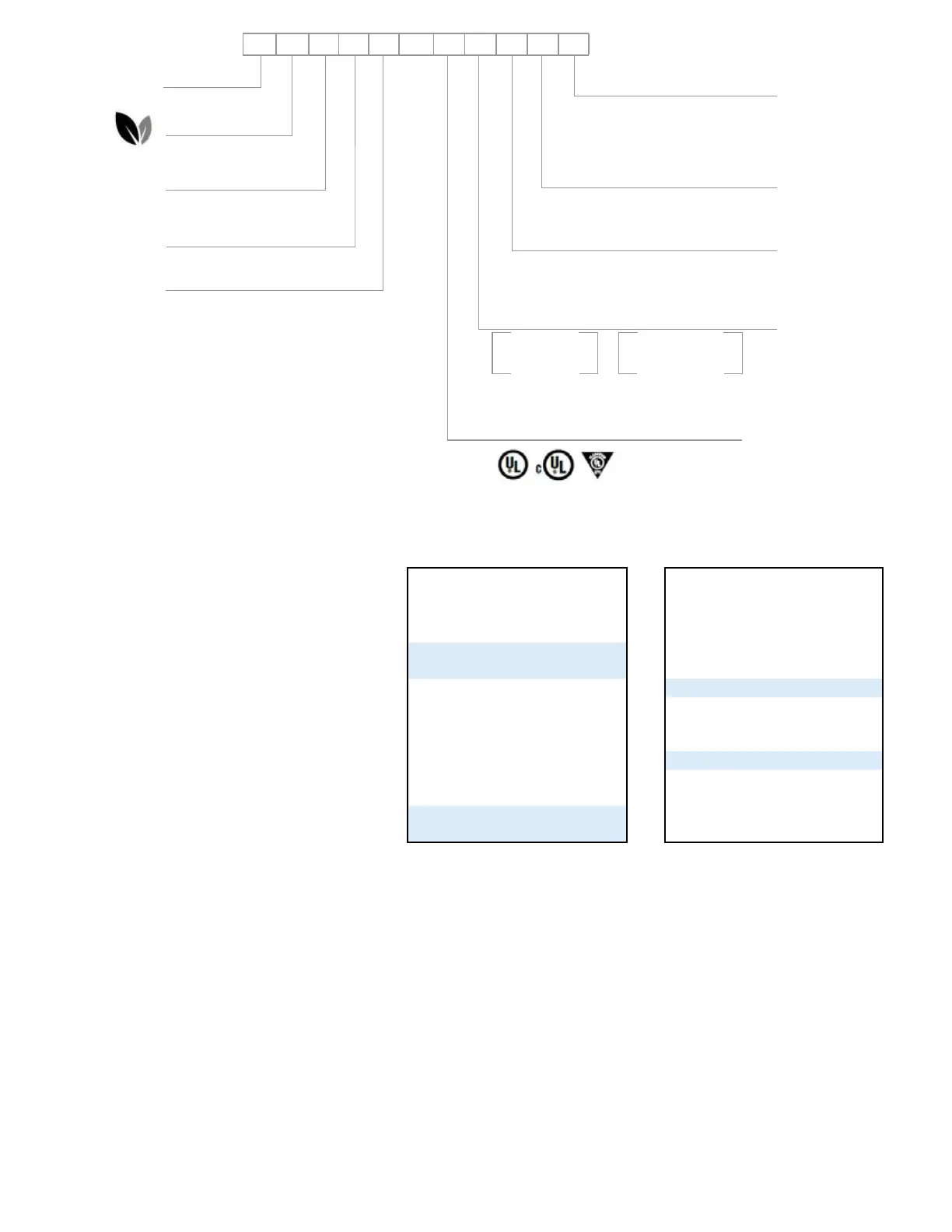

5KR Electrical Defrost Unit Coolers (PN E108318_S)

KR D 2 6 A - 125 T D A A

Unit Type

KR - Compact Series

DOE Application

D - DOE and NR Can

A - Non-Regulated

Number of Fans

4, 6 FPI

Fin Spacing

Type of Defrost

E - Electric Deftost with Electric Pan Heat

A - Air Defrost

G - 3 Pipe Hot Gas with Gas Pan Heat

H - 3 Pipe Hot Gas With Electric Pan Heat

K - 2 Pipe Kool Gas with Gas Pan Heat

P - 2 Pipe Kool Gas with Electric Pan Heat

R - Heat Reclaim

Heater Voltage

B - 115/1/60*

A - 208-230/1/60

K - 208-230/3/60

Motor Voltage

D - Dual Speed EC

A - 208-230/1/60

B - 115/1/60*

S - R-404A

N - Stock Unit***

Refrigerant

B - PSC Motors**

V - Variable Speed EC

Motor Type

BTU/H in Hundreds (00)

B - Glycol / Brine C- CO

2

F - R-407F R - R-449A

Q - R-407A T - R-448A

G - Stock Unit****

P - R-507A

*Available on pan heaters for “H” and “P” defrost options only.

** PSC motors are not allowed for DOE/NRCan regulated applications.

DOE/NRCan applications will require Dual Speed or Variable Speed EC fans.

*** N Stock Units are for non-glide or glide refrigerants

**** G Stock Units are for glide refrigerants only

Additional refrigerants are shown

in the TABLE classied as Glide

and Non- Glide for selection of dual

speed or variable speed motors to

meet DOE/NRCan regulations.

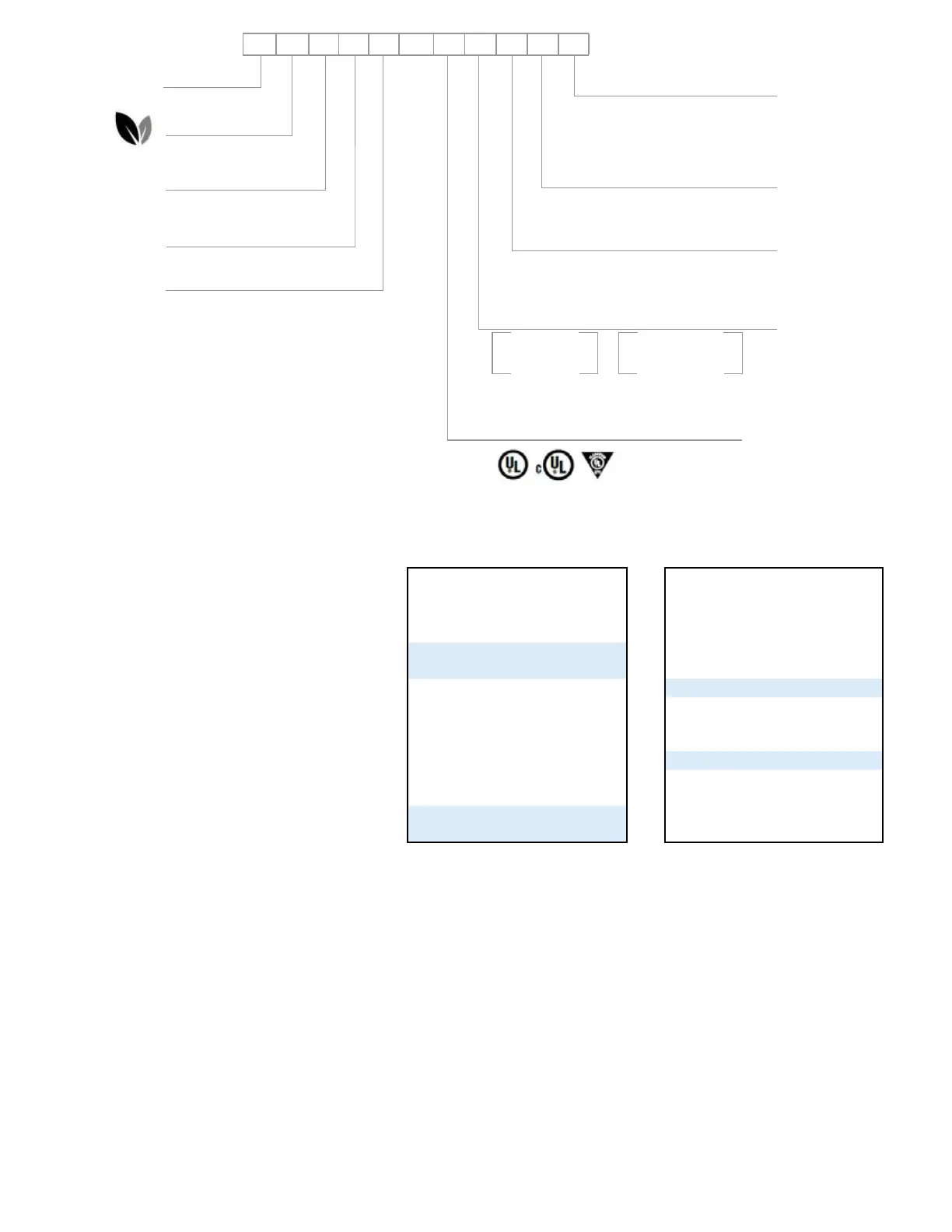

Glide Refrigerants Non-glide refrigerants

Dewpoint to bubble TD Dewpoint to bubble TD

R-401A 9.8 R-134a 0

R-401B 9.4 R-22 0

R-407A 10.5 R-402A (HP80) 2.6

R-407F 10.6 R-402B 3.1

R-407H 11.4 R-404A 1

R-409A 14.8 R-408A 0.7

R-409B 13.5 R-410A 0.2

R-417A 7.6 R-502 0

R-422A 7 R-507A 0

R-4220 7 R-513A 0.1

R-438A 10.8

R-448A 10.5

R-449A 9.7

1 RECEIPT OF EQUIPMENT

1.1 INSPECTION

All equipment should be carefully checked for damage or shortages as soon as it is received. Each shipment should

be carefully checked against the bill of lading. If any damage or shortage is evident, a notation must be made on the

delivery receipt before it is signed, and a claim should then be led against the freight carrier.

1.2 LOSS OF GAS HOLDING CHARGE

Each unit cooler is leak tested, evacuated to remove moisture and then shipped with a gas holding charge. Absence

of this charge may indicate a leak has developed in transit. The system should not be charged with refrigerant until it

is veried that there is no leak, or the source of the leak is located.

2 LOCATION RECOMMENDATIONS

For all defrost types (Air, Electric and Hot gas defrost) unit coolers must have proper airow to maintain a uniform

room temperature and have a complete defrost.

These units are draw thru design thus drawing air thru the cooling coil and discharging it into the room via the unit

fans. For best performance it is desirable to arrange the air discharge toward the door of the cooler to minimize

the entrance of warm moist air when the door is open. The unit must be at least 12 inches from the wall to assure

proper air intake.

Loading...

Loading...