14

Chassis

Chassis

Fuel Tank Mounting/Height Adjustment Screws

Steering Damper Adjusting Knob

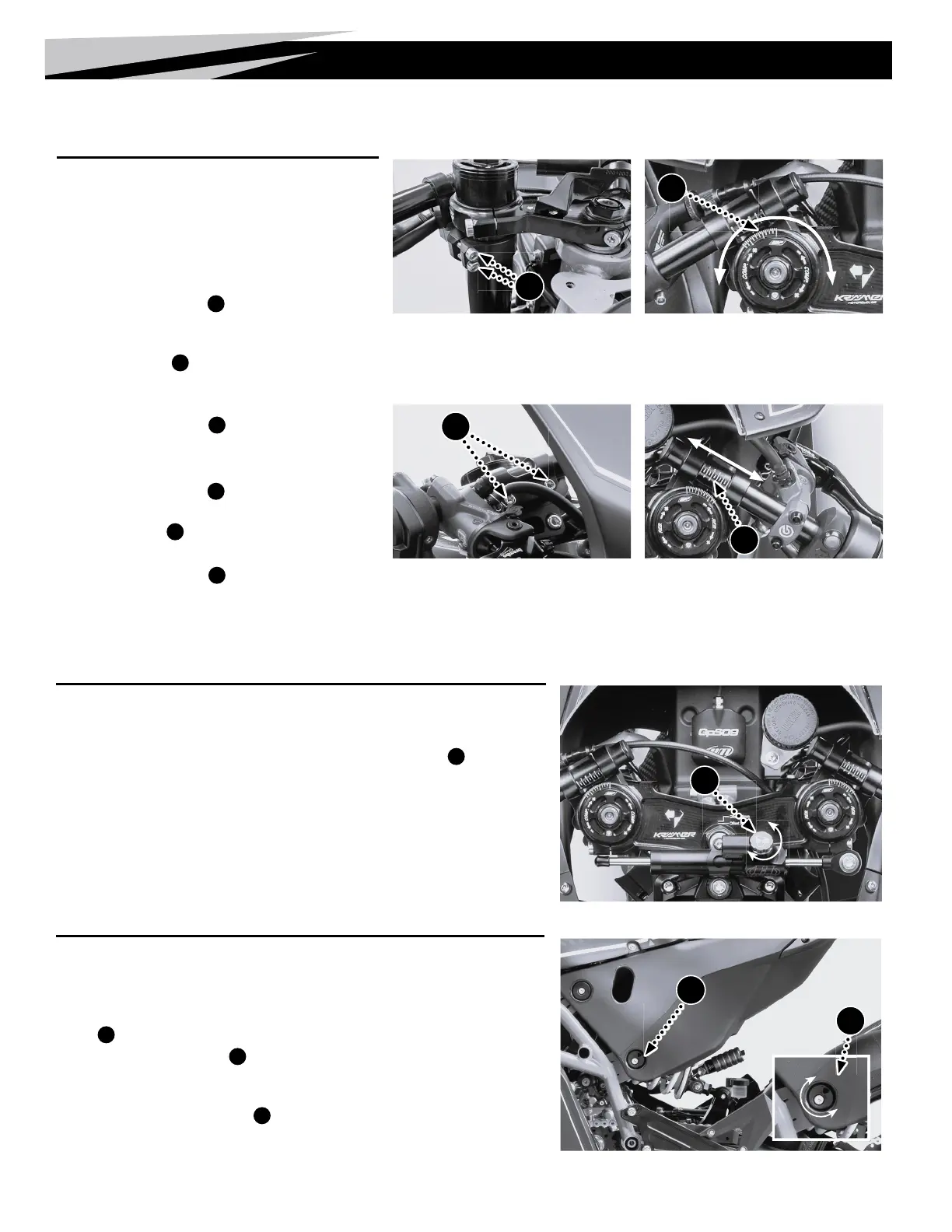

Handlebar Height and Angle Adjustment

Handlebar Width Adjustment

Handlebar Adjustment

The position of the handlebars is adjustable in both height and

angle. Please note that the right and the left handlebar sides

mirror each other, and neither should be at a different angle

or height.

Height and Angle Adjustment

1. Loosen the clamping screws

A

of the clip-ons on both sides.

2. Adjust the height of the handlebars by sliding them up or down on

the fork tube. Adjust the angle by rotating around the fork tube.

Use the angle marks

B

to ensure that both sides are equal.

3. Swing handlebars from lock to lock, making sure nothing touches

or rubs.

4. Tighten the clamping screws

A

of the clip-ons alternately until

the appropriate torque is attained – 10 Nm (7.4 ft-lb).

Width Adjustment (2 positions)

1. Loosen the clamping screws

C

of the clip-ons on both sides.

2. Adjust the width of the handlebars. Read the setting marks at the

edge of the window

D

. Ensure that both sides are equal.

• Check the steering for binding and kinked cables or lines.

3. Tighten the clamping screws

C

of the clip-ons alternately until

the appropriate torque is attained – 10 Nm (7.4 ft-lb).

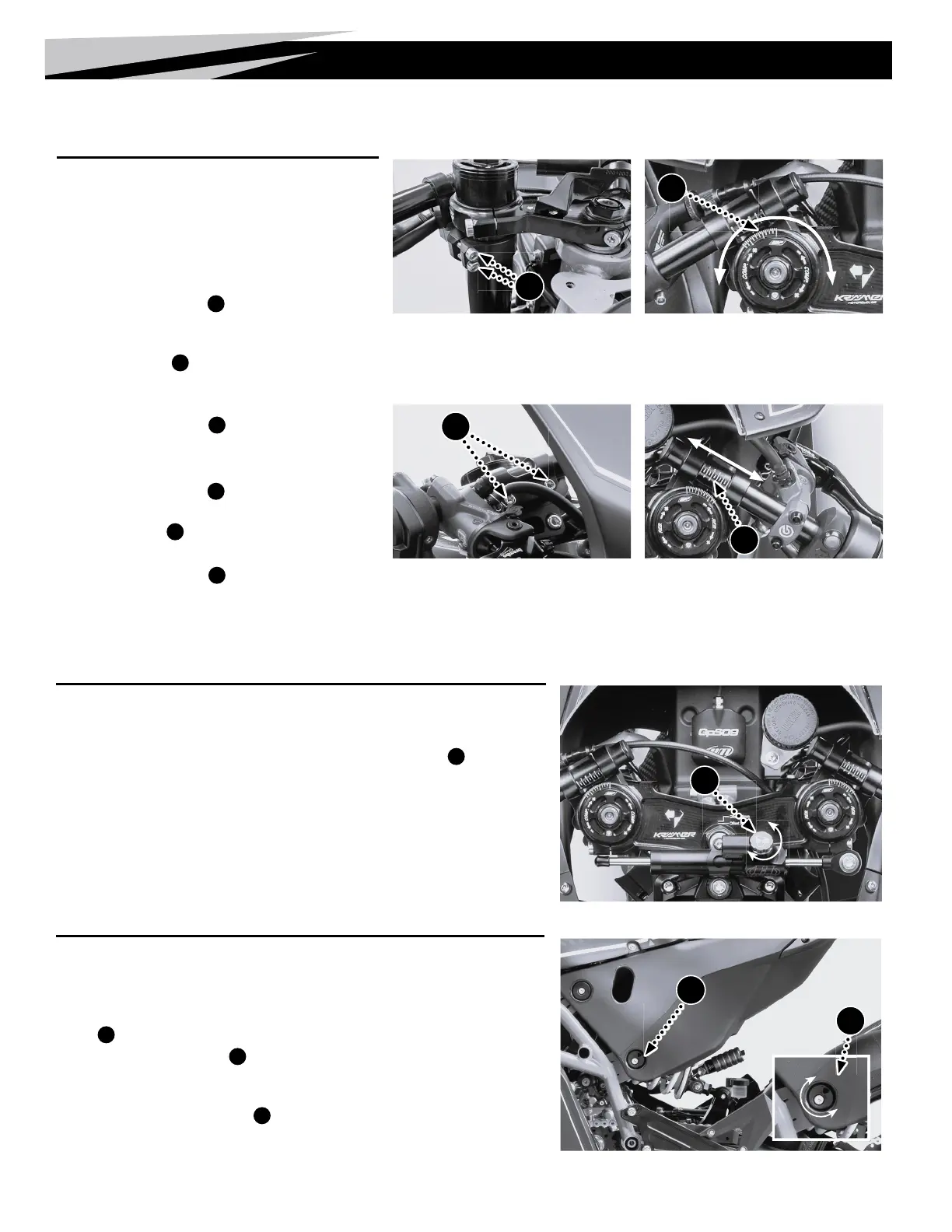

Steering Damper Setup

Setting the steering damper’s rmness

is dependent on riding style and track

characteristics. In high-speed corners, a

higher setting may help keep the motorcycle

more stable. However, too high of a setting in

tight and twisty sections may cost valuable

agility and precision.

Adjust Damper Firmness

1. Rotate the adjusting knob

E

clockwise to the

last detectable click.

2. Adjust to the desired rmness by turning the

adjusting knob counter-clockwise.

• The Adjustment Range is 1-24 clicks

The standard is 12 clicks.

E

A

C

B

D

Seat/Tank Height Adjustment

The seat height is adjusted by moving

the complete seat/tank unit. The height

is adjusted by turning the eccentric tank

mounts

G

.

1. Loosen the bottom mount screws

F

on both

sides of the tank.

2. Using a 6 mm Allen wrench placed in the

triangular hole, turn the eccentric base

G

to

the desired seat position.

3. Temporarily tighten the left mounting screw.

4. Remove the right mounting screw, apply

blue thread lock*, reinsert and tighten to the

appropriate torque – 30 Nm (22.1 ft-lb).

5. Remove the left mounting screw, apply blue

thread lock*, reinsert and tighten to the

appropriate torque – 30 Nm (22.1 ft-lb).

* Loctite

®

243™

F

G

Loading...

Loading...