5 Installation at Site

23 of 64

KWP-Bloc

NOTE

Installing check and shut-off elements in the system is recommended, depending on

the type of plant and pump. However, such elements must not obstruct proper

drainage or hinder disassembly of the pump.

ü The suction lift line has been laid with a rising slope, the suction head line with a

downward slope towards the pump.

ü A flow stabilisation section having a length equivalent to at least twice the

diameter of the suction flange has been provided upstream of the suction flange.

ü The nominal diameters of the pipelines are equal to or greater than the nominal

diameters of the pump nozzles.

ü The pipelines have been anchored in close proximity to the pump and connected

without transmitting any stresses or strains.

1. Thoroughly clean, flush and blow through all vessels, pipelines and connections

(especially of new installations).

2. Before installing the pump in the piping, remove the flange covers on the

suction and discharge nozzles of the pump.

CAUTION

Welding beads, scale and other impurities in the piping

Damage to the pump!

▷ Remove any impurities from the piping.

▷ If necessary, install a filter.

▷ Observe the information in (ðSection7.2.2.1,Page40) .

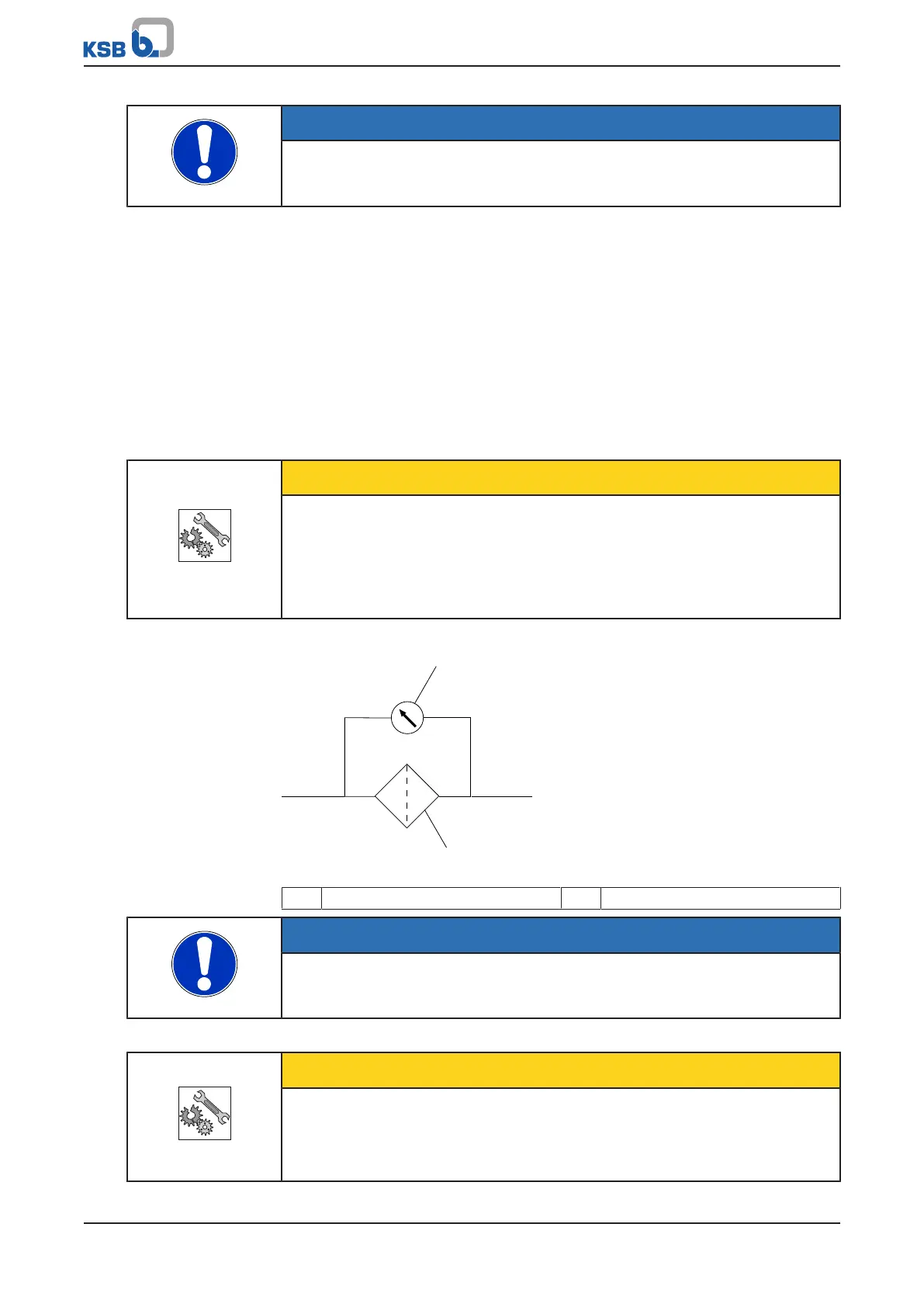

3. If required, install a filter in the piping (see drawing: Filter in the piping).

Fig.5: Filter in the piping

1 Differential pressure gauge 2 Filter

NOTE

Use a filter made of corrosion-resistant material.

Use a filter with a filter area three times the cross-section of the piping.

Conical filters have proved suitable.

4. Connect the pump nozzles to the piping.

CAUTION

Aggressive flushing liquid and pickling agent

Damage to the pump!

▷ Match the cleaning operation mode and duration of flushing and pickling to

the casing materials and seal materials used.

Loading...

Loading...