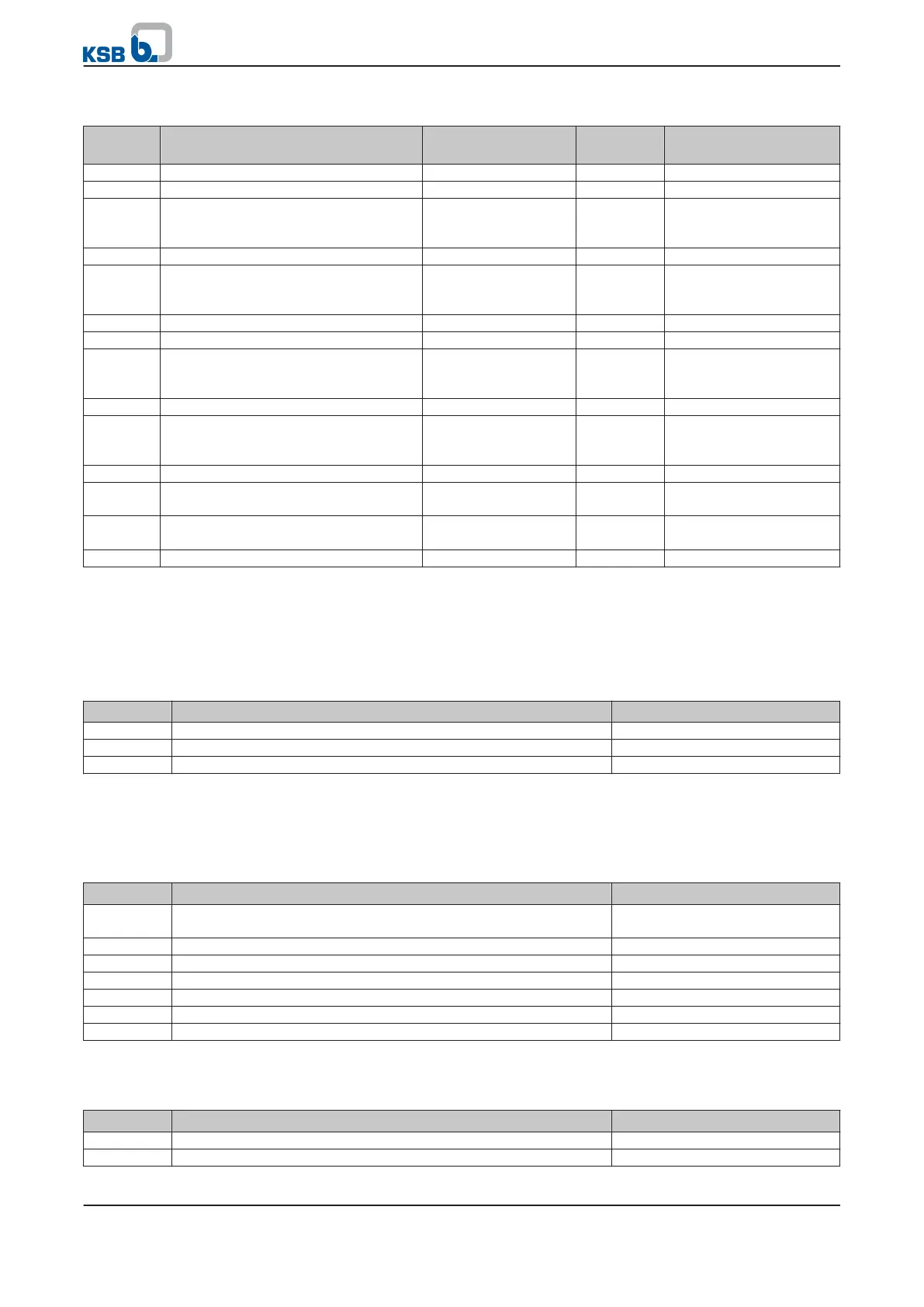

Table 61: Start and stop parameters in multiple pump configurations

Paramete

r

Description Possible settings Reference

to

Factory default

3-6-4-1

High load at low motor frequency 0..100 [%]

3-3-2-1

60 %

3-6-4-2

High load at high motor frequency 0..100 [%]

3-3-2-1

90 %

3-6-4-3

High load profile Linear

Square

Cubic

- Linear

3-6-4-4

High load time delay 0 - 30 [s] - 5 s

3-6-4-5

Function for high load warning No Function

Warning

Stop and Trip

- No Function

3-6-4-6

Low load at low motor frequency 0..100 [%]

3-3-2-1

30 %

3-6-4-7

Low load at high motor frequency 0..100 [%]

3-3-2-1

60 %

3-6-4-8

Low load profile Linear

Square

Cubic

- Linear

3-6-4-9

Low load time delay 0..30 [s] - 10 s

3-6-4-10

Function for low load warning No Function

Warning

Stop and Trip

- No Function

3-3-21

Nominal motor power 0,55..45 [kW] - Depending on the size

3-6-1-2

Lower limit for motor frequency 0 [%] to Frequency

High

(3-6-1-3)

3-11-4-1

50 %

3-6-1-3

Upper limit for motor frequency Frequency Low

(3-6-1-2)

to 100 [%]

3-11-4-1

100 %

3-11-4-1

Maximum output frequency 1 - 70 [Hz] - 50 Hz

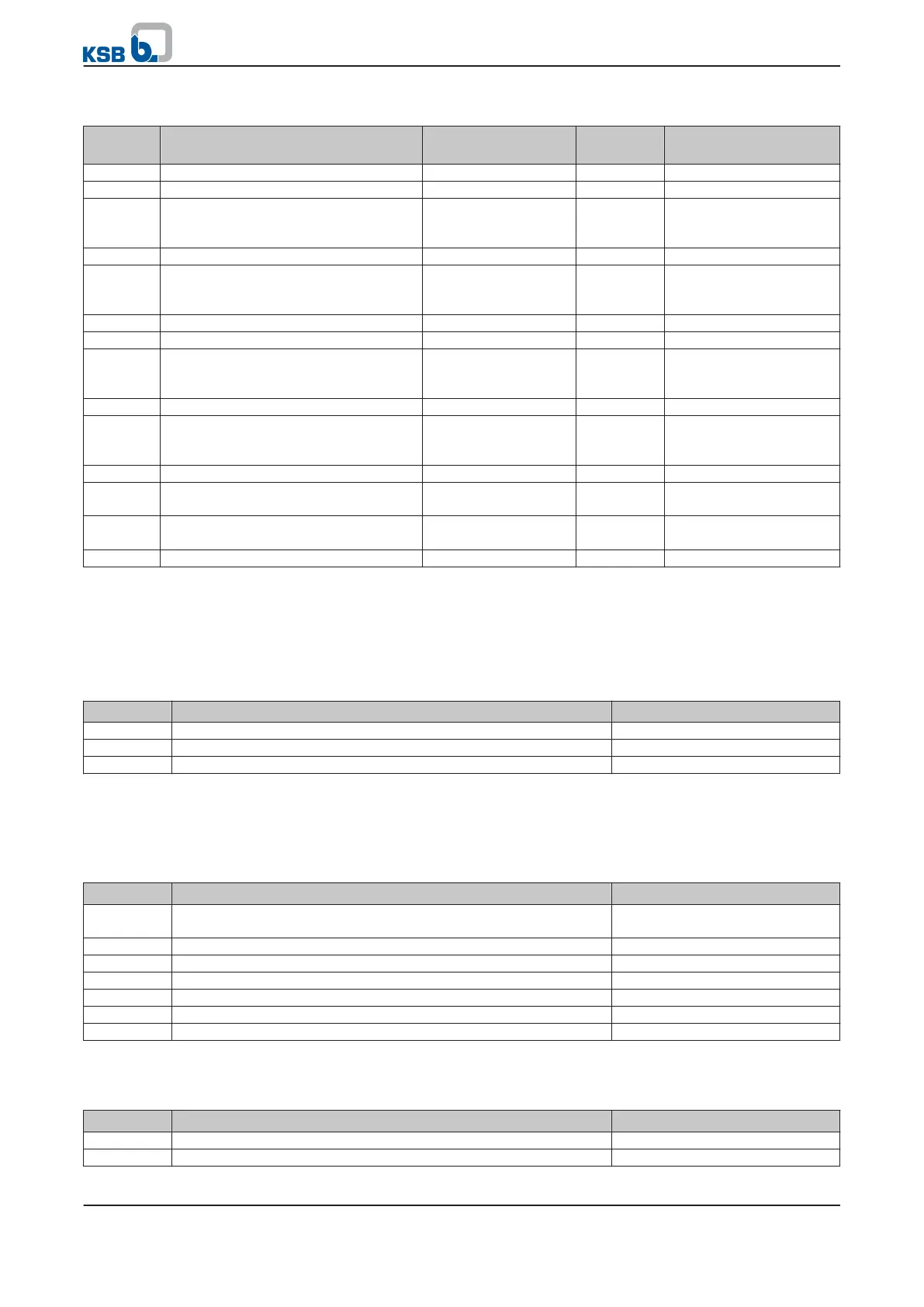

7.1.3.2 Configuration example

The following parameterisation example applies to a multiple pump configuration

with a main pump, an auxiliary main pump and a slave pump. The PumpDrives used

are equipped as follows:

Table 62: Multiple pump configuration example

PumpDrive Role Control panel

1 Main pump with active master control panel Advanced

2 Auxiliary main pump with auxiliary master control panel Advanced

3 Slave pump Standard

The parameter settings of the individual PumpDrives have to be made/checked as

follows:

Parameterise PumpDrive1 with active master control panel

Table 63: Configuration example for multiple pump operation: PumpDrive 1

Parameter Description Value

3-1-7-4

Time value for identifying the control panel as the active master

control panel

1.0 s

3-2-1-1

Role in multiple pump configuration Auxiliary main pump

3-2-1-2

PumpDrive ID 1

3-7-1-2

Function of digital input 2 System start

3-10-1-3

Time value for identifying the control panel as the main pump 2.5 s

3-12-5-1

Maximum number of pumps running simultaneously 2

3-12-5-5

Pump changeover Enabled

Parameterise PumpDrive 3 using the active master control panel of PumpDrive 1:

Table 64: Configuration example for multiple pump operation: PumpDrive 3

Parameter Description Value

3-1-1-4

Selection of a PumpDrive from the multiple pump configuration Pump 3

3-2-1-1

Role in multiple pump configuration Standard slave

7 Commissioning/shutdown

PumpDrive

67 of 162

Loading...

Loading...