3 4

Discharge duct

This duct continuously prolongs the chipping wheel shielding and serves for

directing chips being ejected. The duct can turn in 360

o

and its end piece

(“tilting gate”) serves also for setting the range of ejected chips.

Slewing gear

It serves for directing the chipper at work against its chassis. This sewing gear

provides 12 turning positions and in the given position it can be locked by a

safety pin. This pin is controlled by means of a stranded wire from the loading

chute. On the slewing gear framing there are functional parts of the chipper

installed.

Driving Engine

The chipper is driven by a Lombardini engine, air-cooled and located under its

hinged hood. The engine is controlled by means of elements outside the

engine compartment, on its right side. The driving power is transmitted to the

chipping wheel pulley by means of three V-belts being tightened for easy start.

Chassis

This chassis, type PG 13, is made by the firm PARAGAN s.r.o. and equipped

with a slewing gear with framing.

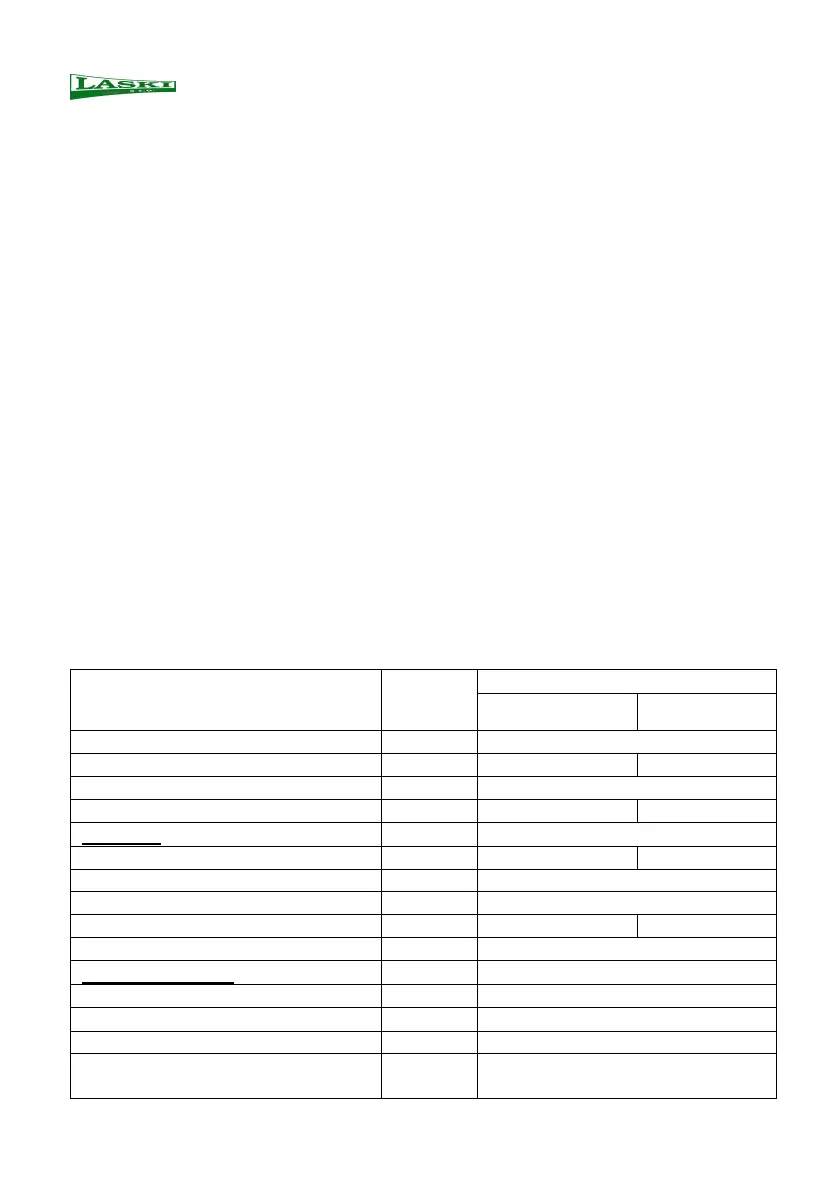

Technical Parameters

Parameter Unit Value

LS 150 D

LS 150 DW

Overall length / for transport

mm 3995 / 3530

Overall width mm 1500 1800

Overall height / for transport mm 2720 / 2030

Weight kg 1100 1260

Chassis:

Type -

PG 13 , PG 16-20 PG 16-20

Manufacturer - PARAGAN s.r.o.

Travel speed km/h 80

Tires - 185 R 14 155 R 13 C

Tire pressure kPa 250

Chipping device:

Chipping wheel – diameter

mm 560

- number of blades

-

2

- rate of cutting

m/s

42

Max. diameter of materials to be

disposed

mm 150

Loading...

Loading...