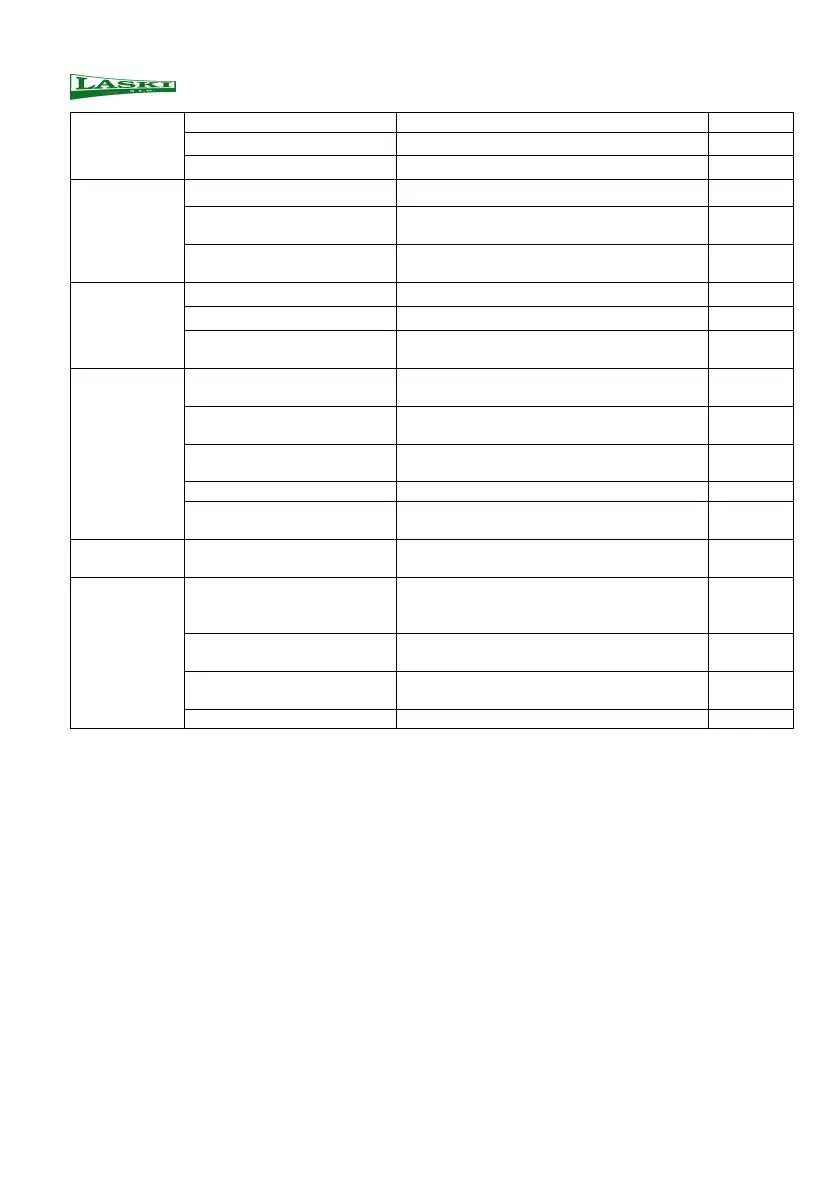

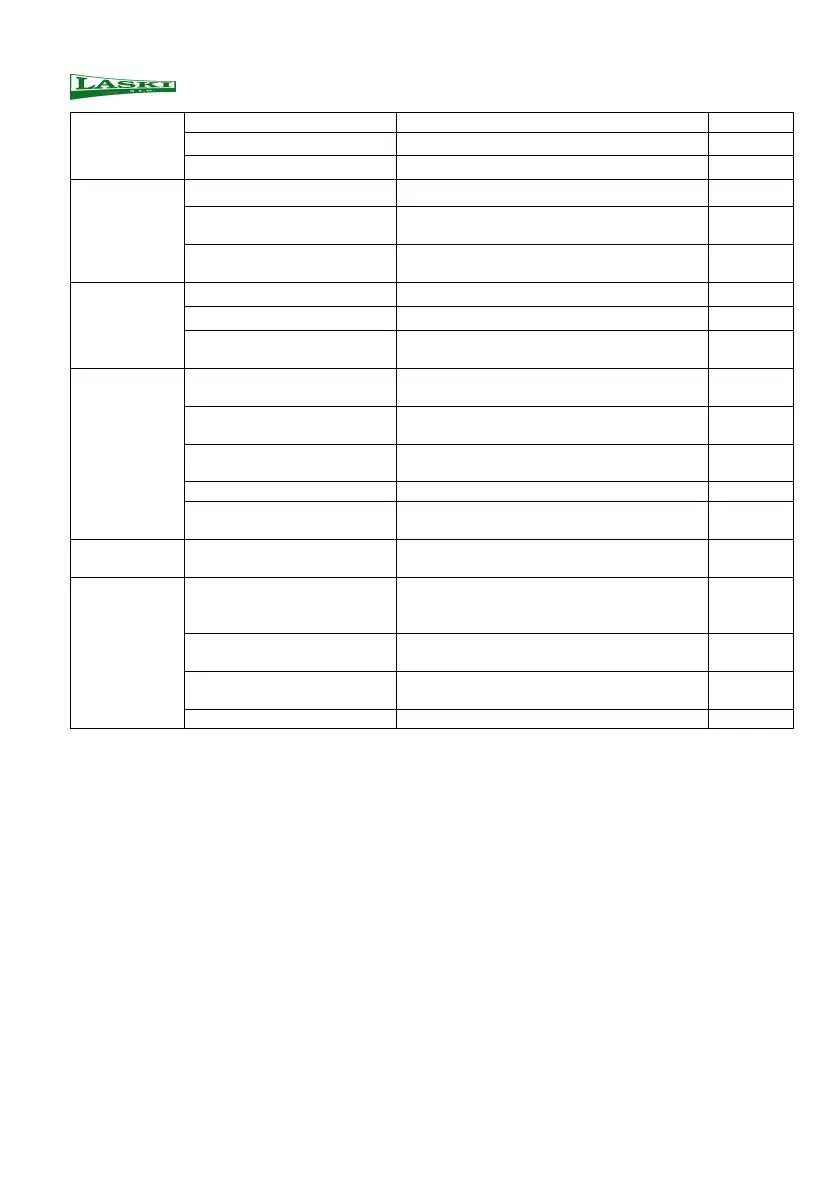

4 5

valve coil

Broken leads Check up wiring for integrity

Faulty hydraulic pump Replacement

NOSTRESS

system out

of function

Blown fuse Replacement of fuse 7,5 A

Faulty electronic control

unit

Replacement of fuse 4 A (inside control

unit) or replacement of control unit

Faulty speed sensor – LED

is not flashing

Check up wiring or replacement of

sensor

Blades touch

opposite

edges

Wrong setting of clearance

Set distance to 0,5 – 1,0 mm

Loosened blade bolts Tighten up fixing bolts

Clearance of chipping

wheel bearings

Tighten up fixing bolt of wheel on its

shaft

Discharge

duct gets

clogged

Low speed of driving

engine

Stop loading and increase engine speed

to maximum.

Too small, dry or rotten

materials

Mix various materials before loading

Discharge ducting

deformed

Repair/replacement

Worn blower vanes Replacement

SERVICE

Loading rolls overloaded

with material

Reduce loading rolls speed

Engine

overheating

fouled cooler clean it

Bearings

overheated

Insufficient lubrication or

wrong lubricant used

Lubrication and lubricants should be in

accordance with recommended intervals

and sorts

Too high speed of chipping

wheel

Optimal speed should not exceed 1500

rpm

Bearing loosened Tighten up bearing housing bolts with

required torque

Bearing worn Replacement

NOTE:

The note "SERVICE" in the "Remedy" column means that this operation should be

done by authorised services only.

Waste Disposal

Waste DisposalWaste Disposal

Waste Disposal

Any waste materials resulting from the machine operation should be disposed

in accordance with laws and regulations applicable in the given country.

Protect nature and water resources against used oil and filter elements.

Any parts of the machine should be disposed in accordance with laws and

regulations applicable in the given country.

Loading...

Loading...