3 8

Adjustment of chipping device

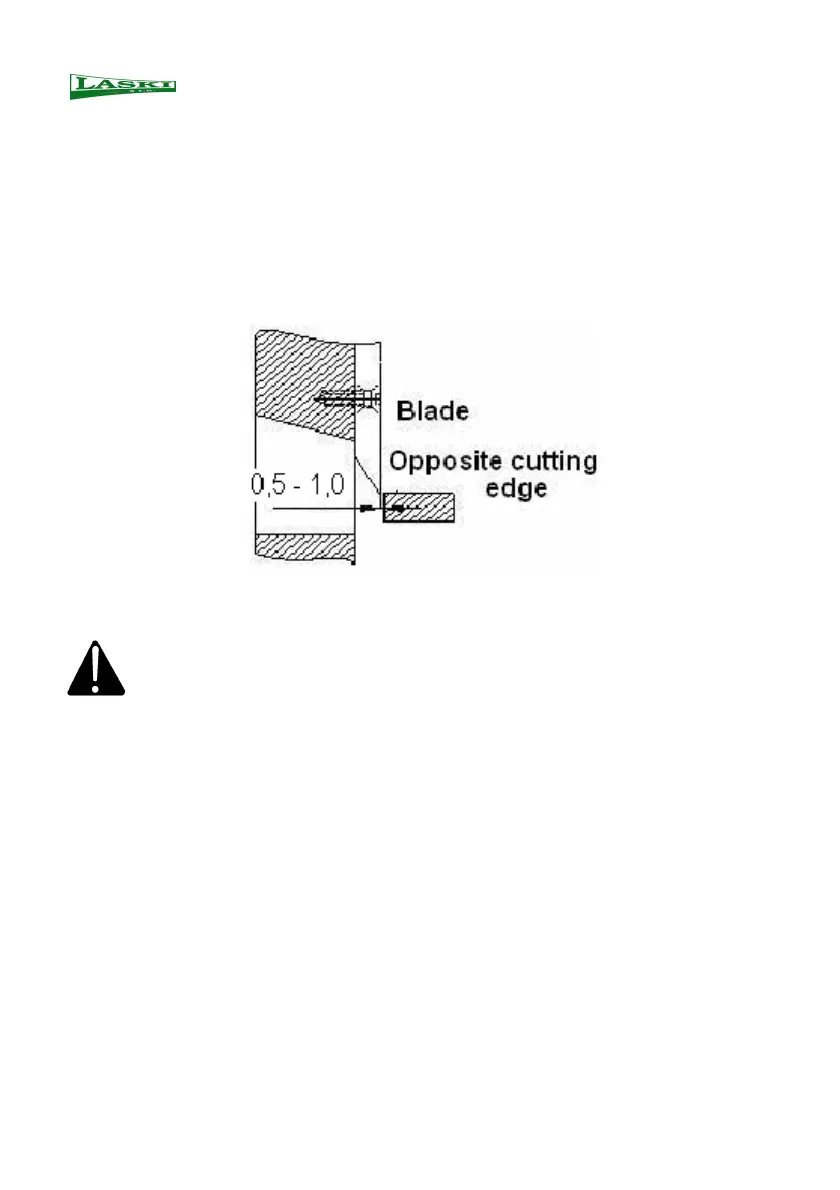

Optimal operation of the chipping device requires right setting of clearance

between the blade and the opposite cutting edge. This distance should be set

(see the following figure) and checked after fitting the ground blades, then it

grows with their wear and chipped branches may be squeezed between the

blade and the opposite edge. It brings deterioration in quality of chipping.

Pay attention also to the blades exchange. In such case set the given

clearance bigger to avoid damage of a new blade and its opposite cutting

edge.

Recommendation: Check out conditions of blades every 40 operating hours.

Regrind blade edges if they are found blunt.

Jointing elements (bolts and nuts) should be replaced together with

The blades exchange. Safety nuts should be used only once, since

they lose their self-locking properties if used repeatedly.

NOSTRESS System – Speed Regulation

This system is intended for overload protection of the combustion engine

consisting of an electronic control unit and a speed sensor installed on the

rotor shaft.

NOSTRESS ON – the chipper works with automatic regulation of loading (no

engine overloading).

NOSTRESS OFF – the chipper works without automatic regulation of loading.

This way of operation is recommended only in case of a failure of the control

unit.

Loading...

Loading...