Page 41

CBX40UHV

START‐UP - OPERATION

Preliminary and Seasonal Checks

1. Make sure the unit is installed in accordance with the

installation instructions.

2. Inspect electrical wiring, both field and factory installed for

loose connections. Tighten as required.

3. Check voltage at disconnect switch. Voltage must be

within range listed on the nameplate. If not, consult the

power company and have voltage condition

corrected before starting unit.

4. Check to ensure that refrigerant lines are in good

condition and pipe insulation is intact.

5. Inspect condition of condensate drain pan and piping

assembly. Disassemble and clean seasonally.

Cooling Start‐Up

NOTE — The following is a generalized procedure and

does not apply to all thermostat control systems. Electronic

thermostat control systems may operate differently.

1. Set fan switch to AUTO or ON and move the system

selection switch to COOL. Adjust the thermostat to a

setting far enough below room temperature to bring on the

compressor. Compressor will start and cycle on demand

from the thermostat.

2. The refrigerant circuit is charged with HFC-410A

refrigerant. See condensing unit rating plate for

correct charge amount.

3. Refer to the correct condensing unit service manual for

more information.

Heating Start‐Up

1. Set the fan switch to AUTO or ON and move the

system selection switch to HEAT. Adjust the

thermostat setting above room temperature.

2. The indoor blower immediately starts and the electric heat

will stage on based on sequence timing.

Safety or Emergency Shutdown

Turn off unit power at circuit breaker.

Extended Period Shutdown

Turn off thermostat or set to UNOCCUPIED mode. Turn off

power to unit. All access panels and covers must be in place

and secured. The condensate assembly should be clean

and dry for extended period shutdown.

OPERATING CHARACTERISTICS

Blower Operation and Adjustment

NOTE — The following is a generalized procedure and

does not apply to all thermostat controls.

1. Blower operation is dependent on thermostat

control system.

2. Generally, blower operation is set at thermostat

subbase fan switch. With fan switch in ON position,

blower operates continuously. With fan switch in AUTO

position, blower cycles with demand.

3. In all cases, blower and entire unit will be off when the

system switch is in OFF position.

External Static Pressure

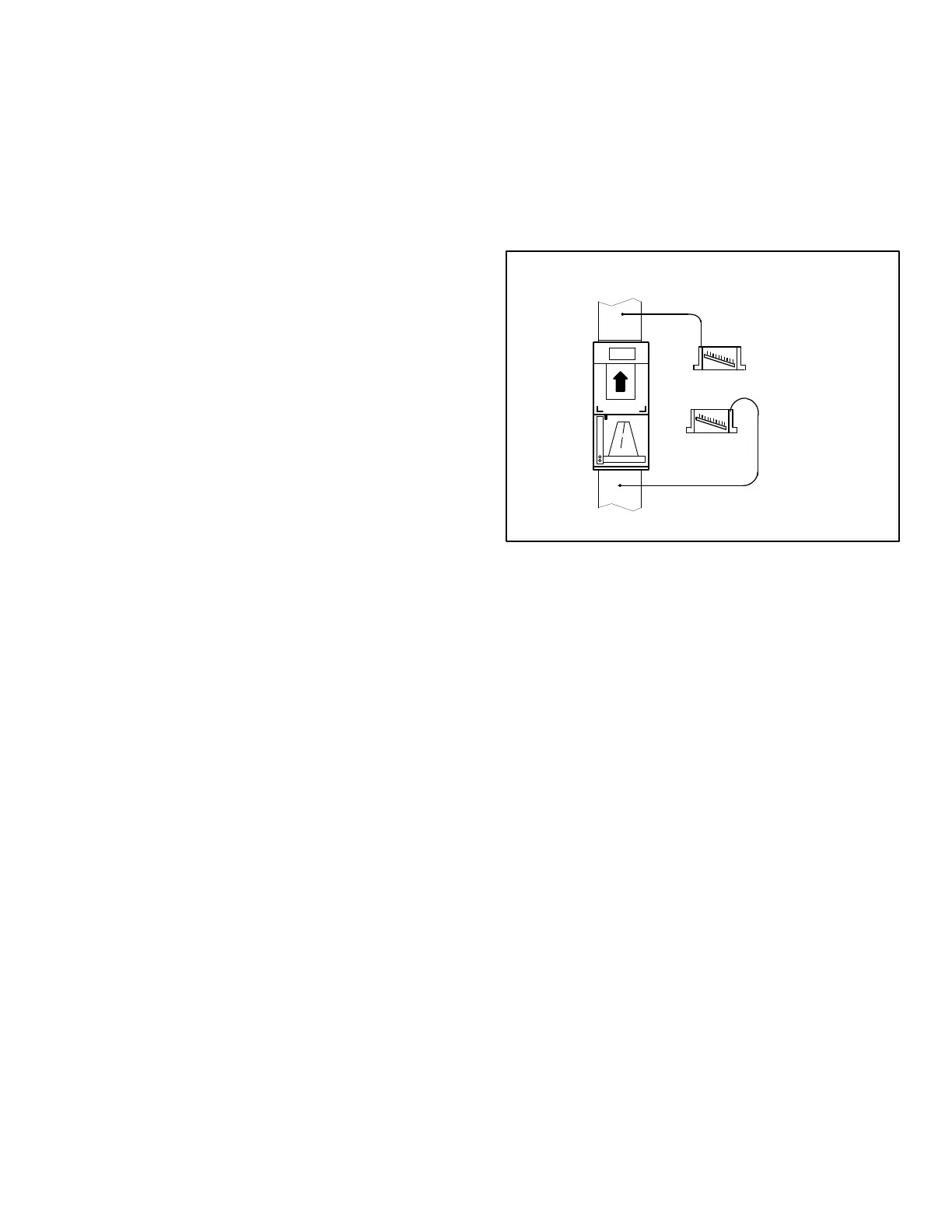

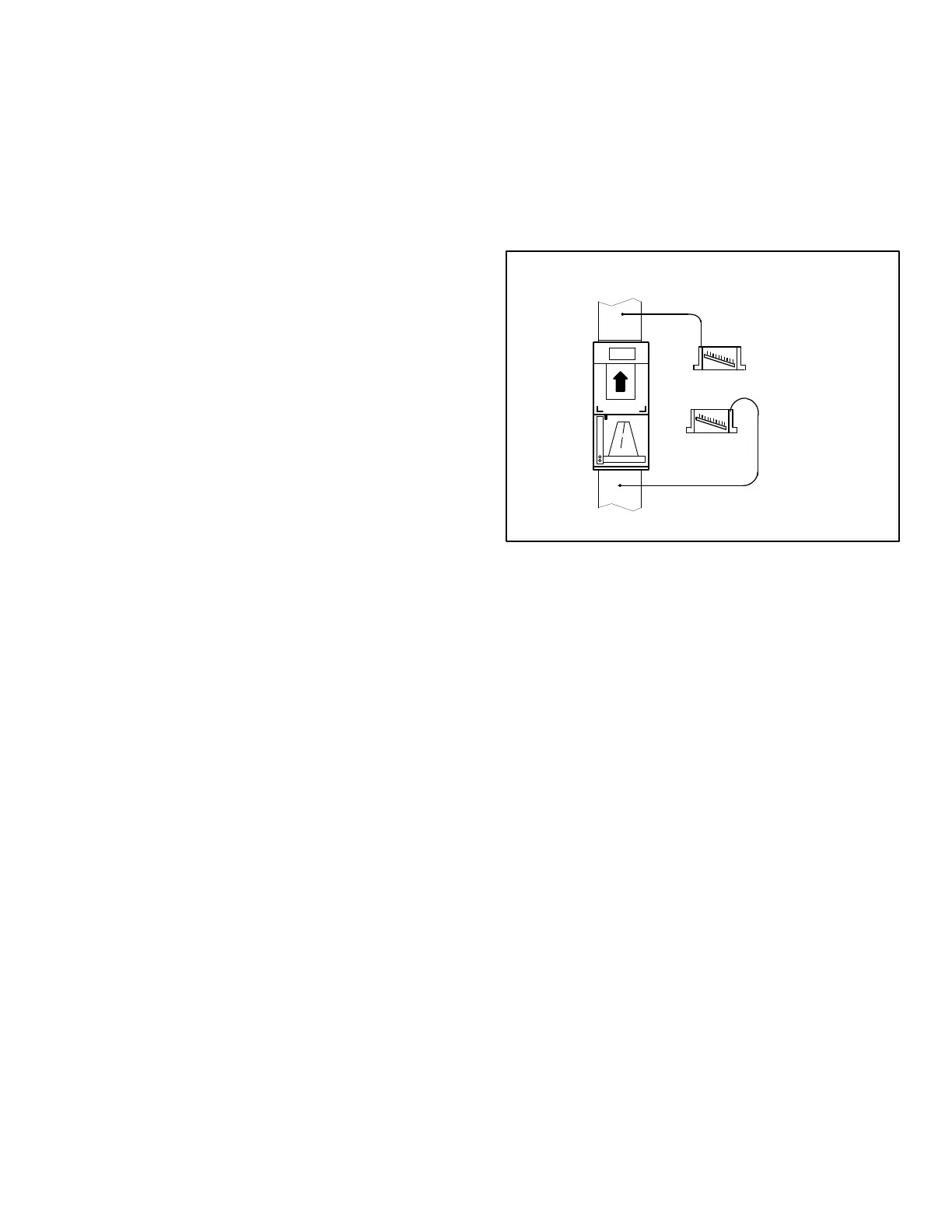

Measure tap locations as shown in figure 31.

MANOMETER

SUPPLY

RETURN

UNIT SHOWN IN

Up-Flow POSITION

+

_

Figure 31. Static Pressure Test

4. Punch a 1/4” (6mm) diameter hole in supply and return

air plenums. Insert manometer hose flush with inside

edge of hole or insulation in the supply plenum only. Seal

around the hose with permagum. Connect the other end

of the hose to the zero end of the manometer. Leave the

other end of the manometer open to the atmosphere.

5. With only the blower motor running and the

evaporator coil dry, observe and take note of the

manometer reading.

6. Repeat step 2 for the return air plenum. Insert

manometer hose to the opposite end of the zero side

of the manometer. Leave the zero side of the

manometer open to atmosphere.

7. Repeat step 3.

8. Add the absolute values of the supply air reading and

the return air reading to get the external static pressure

of the unit. For example -.20 in. wg. on the return and

+.30 in. wg. on the supply result in external static

pressure of .50 in. wg. External static should not

exceed .80” w.g. (200Pa)

Adjust blower motor speed to deliver the air desired

according to job requirements.

9. Seal around the holes when the check is complete.

Loading...

Loading...