Process data transfer

Lenze device control

Process output data configuration

7

45

EDS82ZAFPC010 EN 4.0

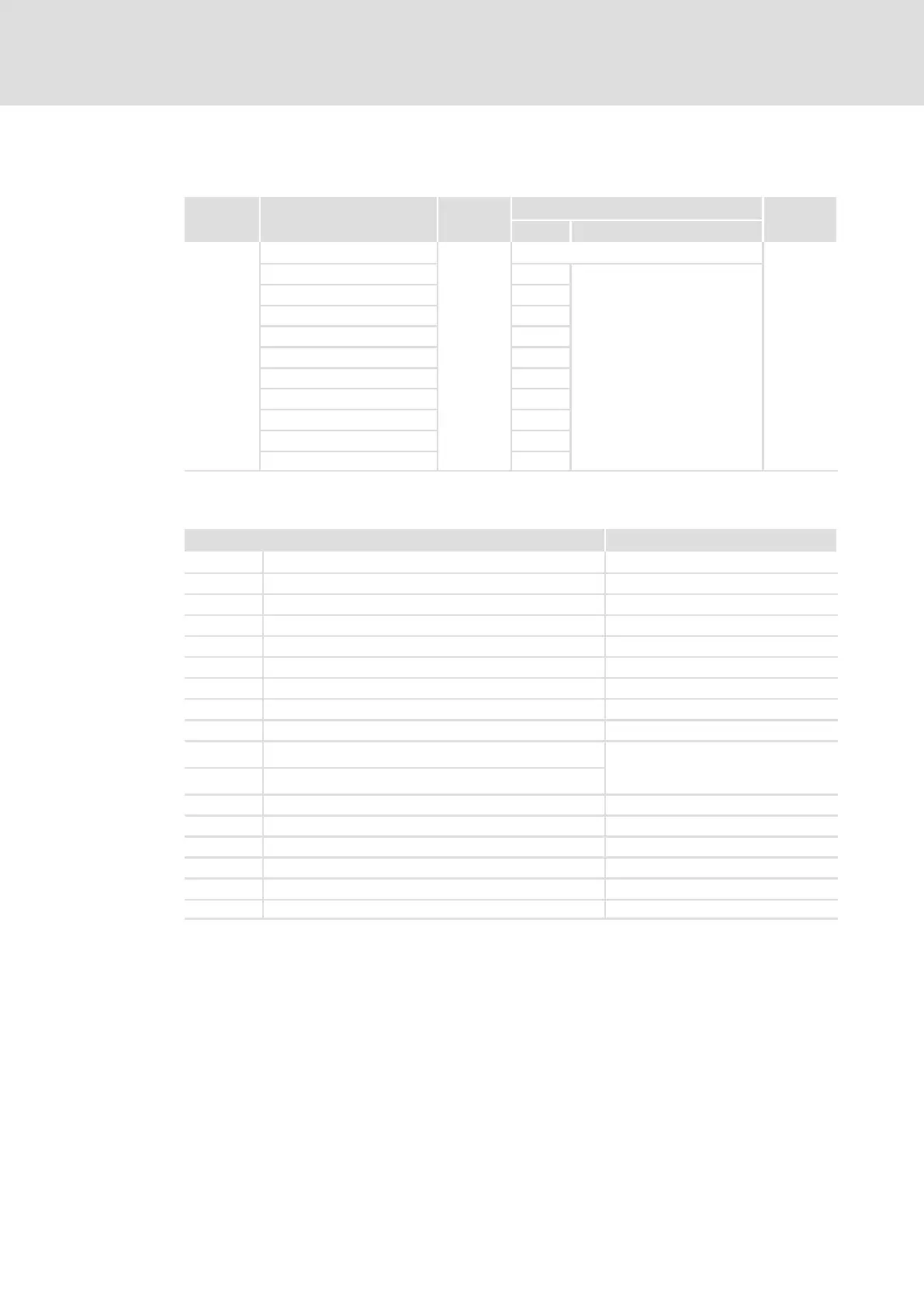

C1511:

Configuration of process output data

Code Subcode Index

Possible settings

Data type

Lenze Selection

C1511 23064

d

=

5A18

h

FIX32

1 (POW1) 17

see table below

2 (POW2) 3

3 (POW3) 4

4 (POW 4) 5

5 (POW 5) 6

6 (POW 6) 7

7 (POW 7) 8

8 (POW 8) 9

9 (POW 9) 10

10 (POW 10) 11

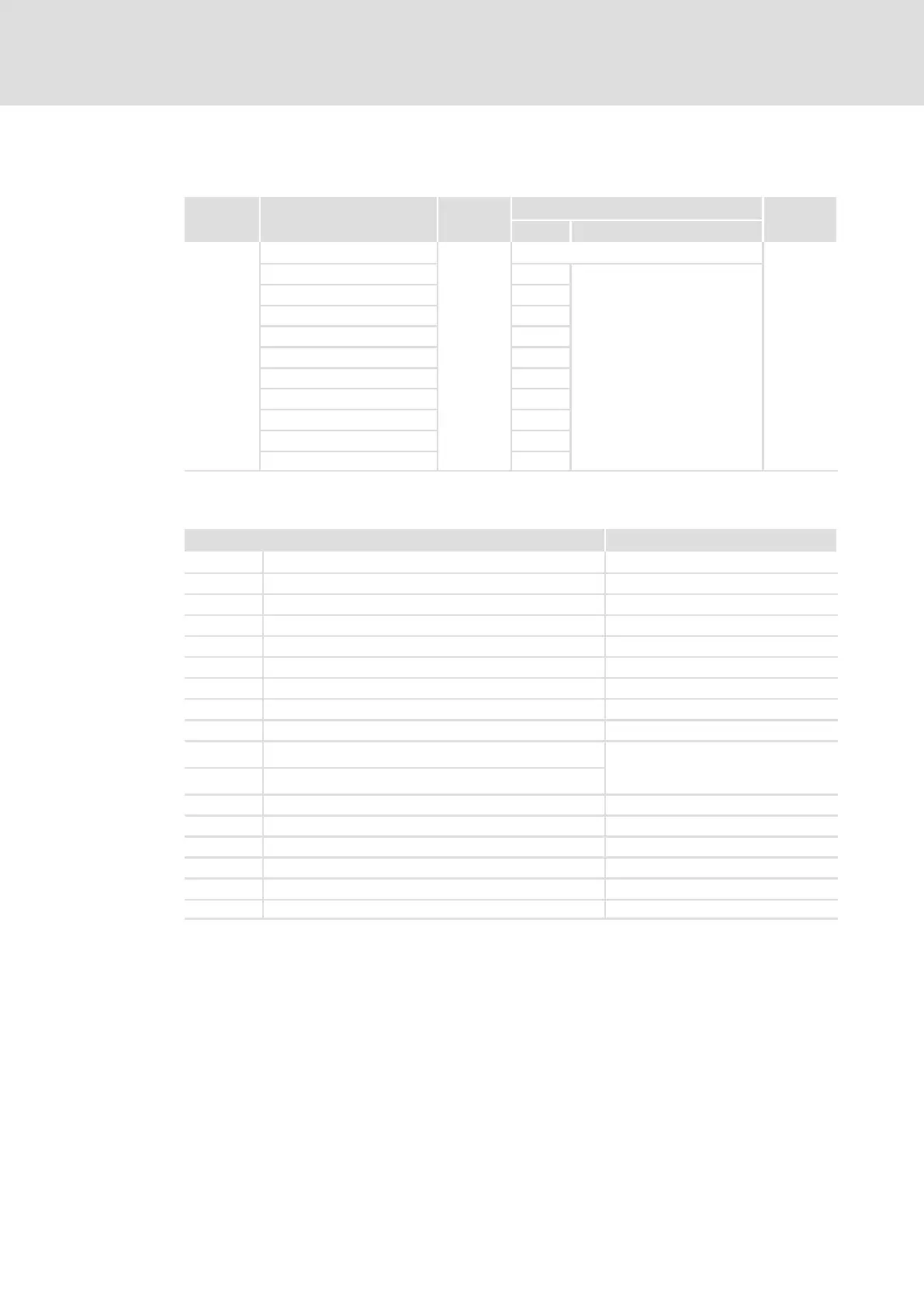

The process data output words (POW) of the master can be freely assigned to bit control

commands or setpoints of the controller via C1511.

Selection Scaling

1 FIF control word 1 (FIF−CTRL1) 16 bits

2 FIF control word 2 (FIF−CTRL2) 16 bits

3 Setpoint 1 (NSET1−N1) ±24000 º ±480 Hz

4 Setpoint 2 (NSET1−N2) ±24000 º ±480 Hz

5 Additional setpoint (PCTRL1−NADD) ±24000 º ±480 Hz

6 Actual process controller value (PCTRL1−ACT) ±24000 º ±480 Hz

7 Process controller setpoint (PCTRL1−SET1) ±24000 º ±480 Hz

8 Reserved

9 Torque setpoint/torque limit value (MCTRL1−MSET) 2

14

º100 % rated motor torque

10 PWM voltage (MCTRL1−VOLT−ADD)

For special applications only.

System manual for 8200 vector

11 PWM angle (MCTRL1−PHI−ADD)

12 Reserved

13 FIF−IN.W1 16 bits or 0 ... 65535

14 FIF−IN.W2 16 bits or 0 ... 65535

15 FIF−IN.W3 0 ... 65535

16 FIF−IN.W4 0 ... 65535

17 DRIVECOM control word (DRIVECOM−CTRL) 16 bits

Loading...

Loading...