Testing

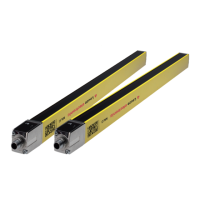

Leuze electronic MLC 520 41

9 Testing

NOTICE

Ä Safety sensors must be replaced at the end of their service life (see chapter 14 "Technical

data").

Ä Always exchange entire safety sensors.

Ä Observe any nationally applicable regulations regarding the tests.

Ä Document all tests in a comprehensible manner and include the configuration of the safety

sensor along with the data for the safety- and minimum distances in the documentation.

9.1 Before the initial start-up and following modifications

WARNING

Unpredictable machine behavior during initial start-up may result in serious injury!

Ä Make certain that there are no people in the danger zone.

Ä Before they begin work, train the operators on their respective tasks. The training is the responsibility of

the operating company.

Ä Attach notices regarding daily testing in the respective national language of the operator on the ma-

chine in a highly visible location, e.g. by printing out the corresponding chapter (see chapter 9.3 "Peri-

odically by the operator").

Ä Test the electrical function and installation according to this document.

Acc. to IECTS62046 and national regulations (e.g. EU directive2009/104/EC), tests are to be performed

by competent persons in the following situations:

• Prior to the initial start-up

• Following modifications to the machine

• After longer machine downtime

• Following retrofitting or new configuration of the machine

Ä As preparation, check the most important criteria for the safety sensor according to the following check-

list (see chapter 9.1.1 "Checklist for integrator – to be performed prior to the initial start-up and following

modifications"). Completing the checklist does not replace testing by a competent person!

ð Not until proper function of the safety sensor is ascertained may it be integrated in the control circuit of

the system.

9.1.1 Checklist for integrator – to be performed prior to the initial start-up and following modifications

NOTICE

Completing the checklist does not replace testing by a competent person!

Ä If you answer one of the items on the following check list with no, the machine must no

longer be operated.

Ä IEC/TS62046 contains additional recommendations on testing protective devices

Tab.9.1: Checklist for integrator – to be performed prior to the initial start-up and following modifications

Check: Yes No not ap-

plicable

Is the safety sensor operated acc. to the specific environmental condi-

tions that are to be maintained (see chapter 14 "Technical data")?

Is the safety sensor correctly aligned and are all fastening screws and

connectors secure?

Are safety sensor, connection cables, connectors, protection caps and

command devices undamaged and without any sign of manipulation?

Loading...

Loading...