User Manual for BPS-2000

www.levitronix.com

PL-4021-00, Rev03, DCO# 15-235

6 Inspection and Maintenance

6.1 Replacement Interval of the Impeller

The impeller has a limited lifetime depending on the chemical type, concentration and temperature of the

fluid which is pumped. Therefore a preventive periodical exchange of the impeller is recommended. Contact

the Levitronix Technical Service Department (see Section 8) for further information on replacement times.

6.2 Impeller Replacement Procedure

6.2.1 Preparation

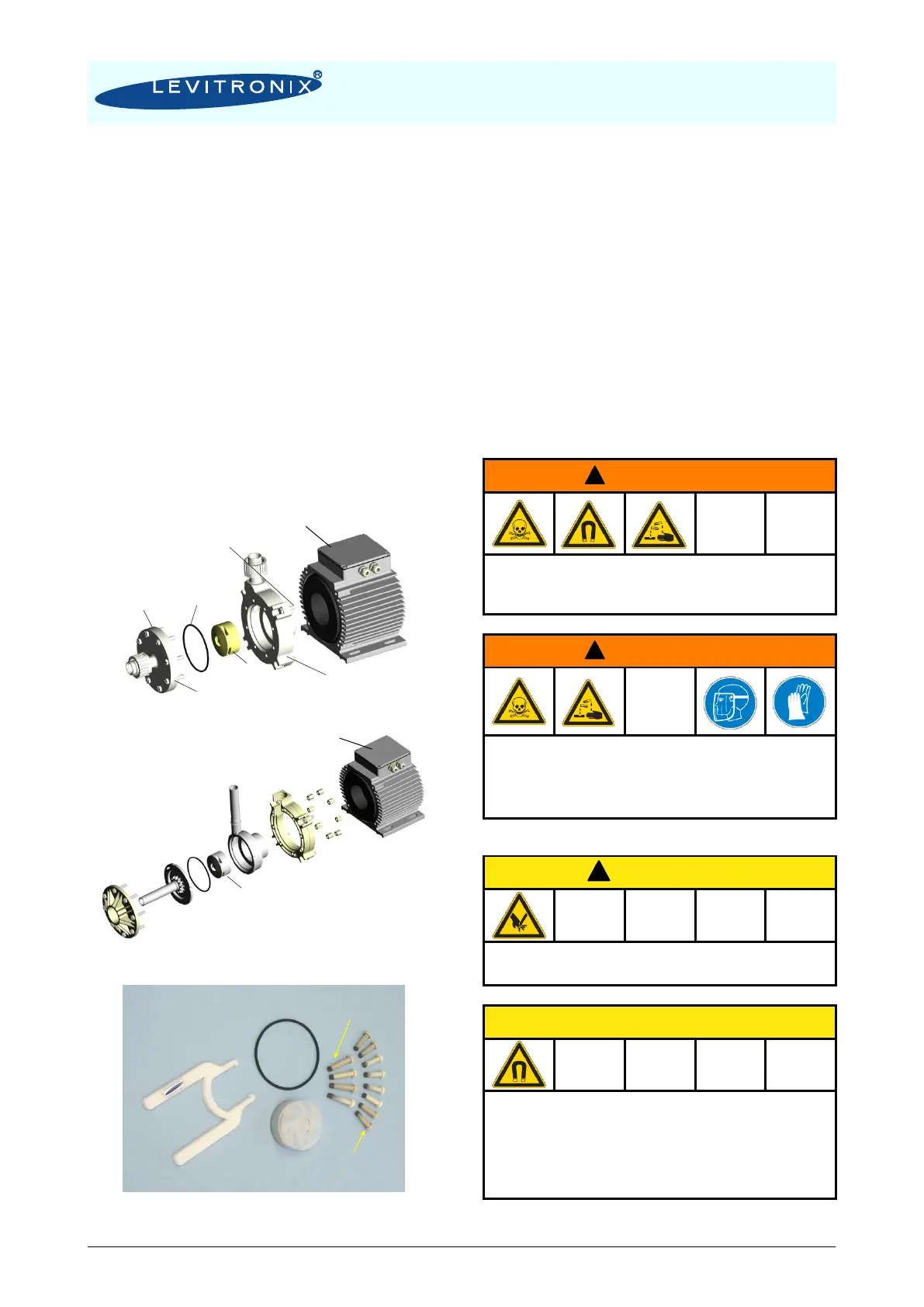

Before starting the impeller replacement procedure

the parts and tools illustrated in Figure 42 should

be prepared. Impeller exchange kits, which contain

these parts are available at Levitronix

®

(see Table

4). For special configurations contact Levitronix

®

.

Please verify that you have the right types of

impellers, O-rings and screws.

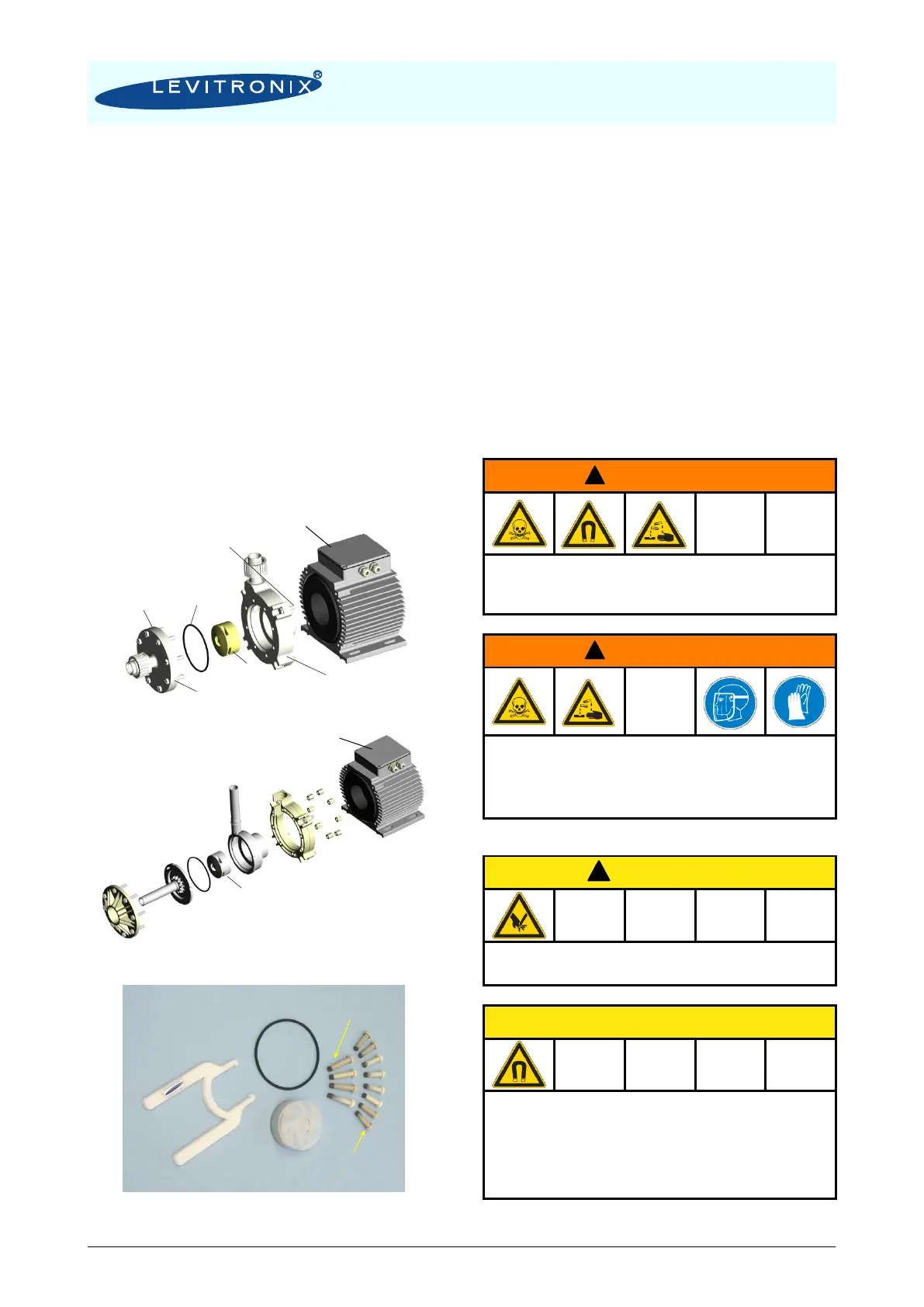

Figure 40: Explosion view of PTFE pump head

Figure 41: Explosion view of PFA+PP pump head

Figure 42: Components for impeller replacement

The following warnings and cautions should be

read carefully before starting the replacement of

the impeller.

The impeller could splash TOXIC or CORROSIVE

CHEMICALS because of the strong magnetic forces.

Flush the pump housing before opening it.

HARMFUL CHEMICALS may be present.

Skin contact and toxic gases may be hazardous to

your health. Wear safety gloves and other appropriate

safety equipment.

The rotating impeller could cause injury. Do not run

the pump system when opening the pump head.

Pay attention to the magnetic forces when handling

the impeller. The attraction of magnetic parts and

particles should be avoided in order to keep the

impeller and the pump head clean and free of

contamination. Avoid magnetic and metal parts within

a radius of about 1 meter.

Loading...

Loading...