Page 272 of 295

Safe Working Load

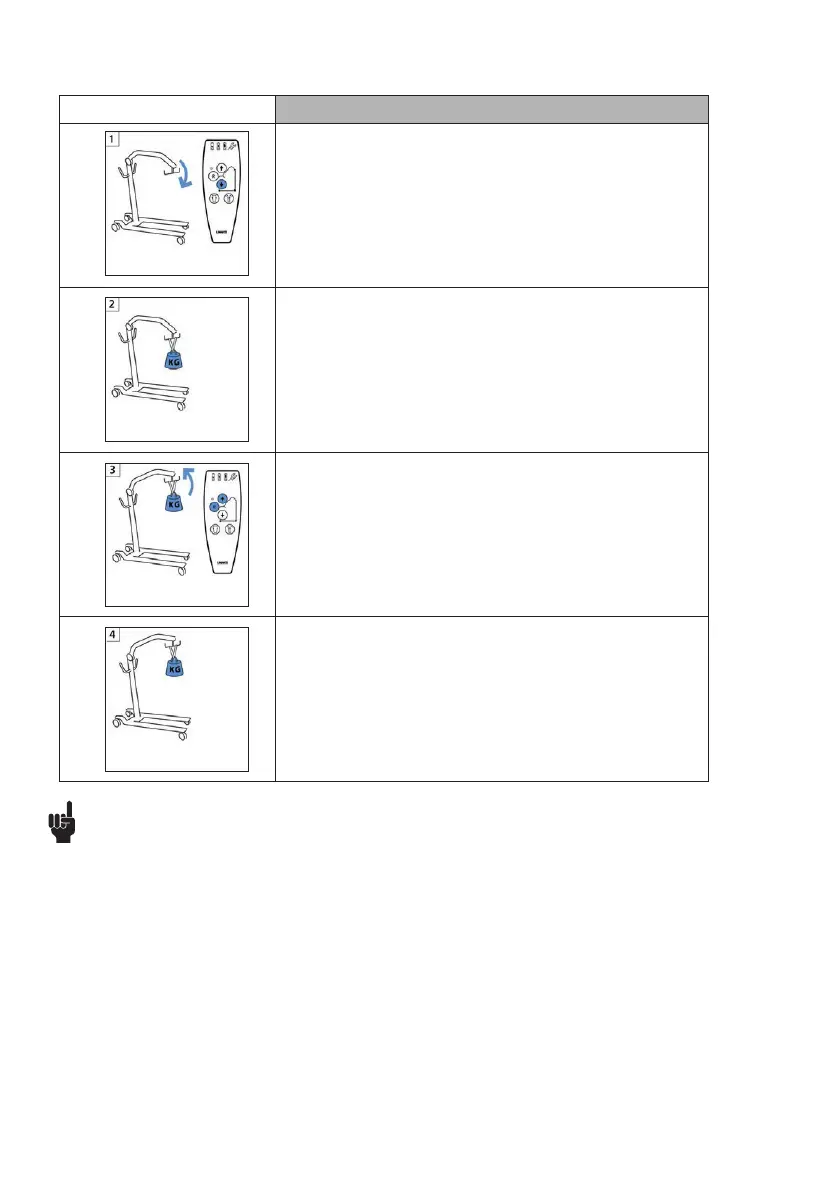

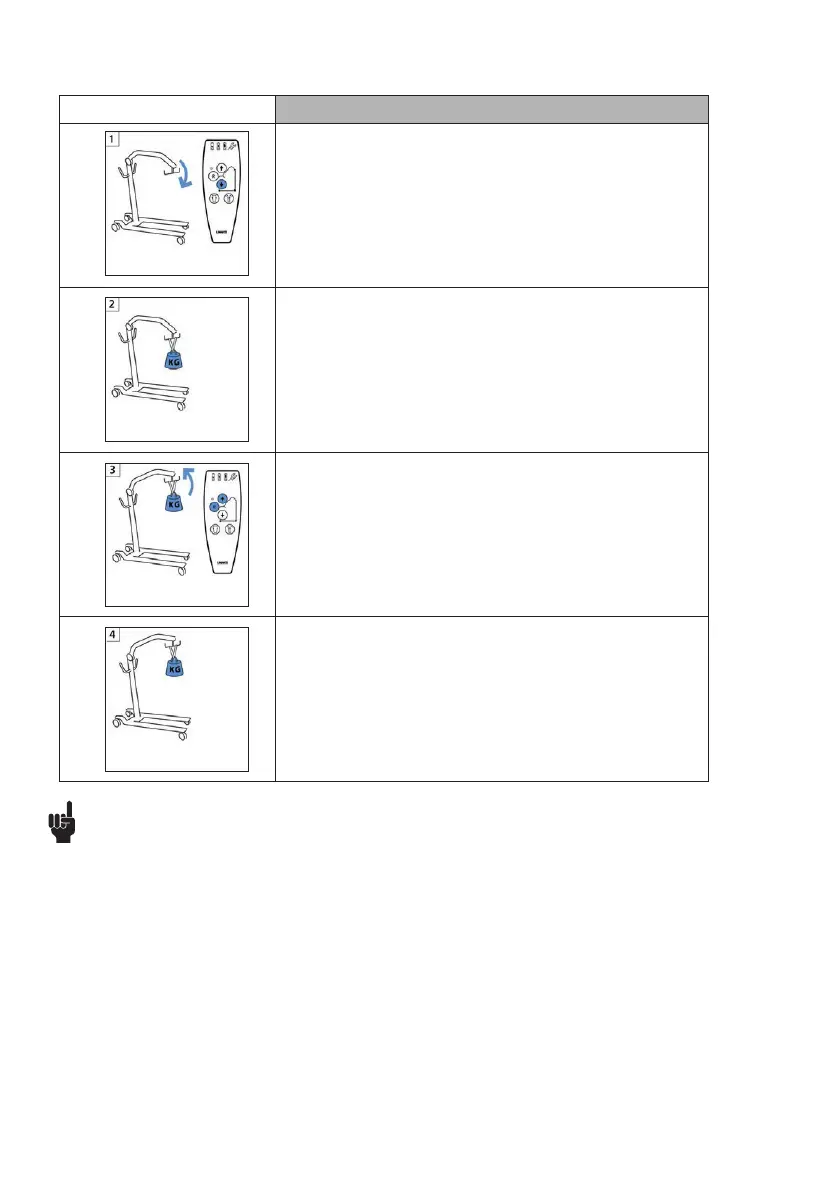

Drive the lifting arm down and connect the special SWL adjustment hand control.

Add load to the lift corresponding to SWL for the lift type.

Press the 'R' and 'UP' buttons simultaneously and move the lifting arm up.

If using the standard SWL adjustment, then it is possible to use the standard

SWL adjustment function without moving the actuator a full stroke, but it must

be ensured that the lifting is carried out in the area where the lift has the biggest

load.

When the actuator stops running, the largest current value is registered and stored

in the control box SW.

When the current cutoff value is stored, the control box will provide an audio

signal and a flashing LED, depending on the SW configuration.

How to use the SWL adjustment function

With LIFT40 it is possible to configure software for the use of the standard or advanced SWL function or even both if needed. When preparing the

control box software, it is possible to make preparations for the use of a standard SWL hand control or the use of a customised hand control.

Recommendations

• Always use locking mechanism and O-ring.

• Using the Safe Working Load (SWL) adjustment functionality allows easy current limit setting to help the lift comply with the ISO 10535 requirement.

• The SWL adjustment functionality is recommended to use for channel 1 when adjusting the lifting actuator to fit the SWL load rating of the lift.

• Based on settings from using the SWL adjustment function, the lift shall not be able to lift more than 1.5 times the maximum load.

However, the current limit setting will not stop the actuator at the exact same load as used for the SWL adjustment.

This is due to the fact that an actuator uses less current when its components have been run in.

• SWL adjustment: When the current limit has been registered, the control box will allow the actuator to draw the registered current plus an addition of 10%.

This ensures that the lift can lift the set load, however it cannot lift more than 1.5 times of the set load.

• When making new current limit settings, be aware to use a defined set of actuator and control box.

To ensure that a new current limit setting is stored in the control box, either the SWL adjustment function must be active for at least 2 seconds or

the actuator has to run minimum 20 mm. The actuator current consumption must be at least 2 A for minimum 2 seconds during the use of

the SWL adjustment function.

• Always use fully charged batteries (as a minimum more than 50% battery capacity) for SWL adjustment procedures.

• CAL40+: A maximum cutoff value of 12 Amp can be registered (stored).

• The ambient temperature must be approx. 20 ºC.

• The difference between the highest and lowest load should exceed 10% if using the standard SWL adjustment function.

• To activate the SWL adjustment function, use the special SWL adjustment hand control.

• If an actuator or a control box is replaced, it is necessary to reset the maximum load to ensure the correct cutoff value for the new system.

• The preset current cutoff value of a specific lift can be reset by means of the SWL adjustment function, however, this may not be in accordance

with EN10535 if done with different loads than the rated load of the lift.

Loading...

Loading...