5 Servicing

Inspection and maintenance every 3000 operating hours or every 2 years

Change pressure filter

ENVIRONMENT NOTE

Take note of information about working ma-

terials. Hydraulic oil will escape so place a

collection vessel underneath beforehand.

¾ Fully lower fork carriage.

¾ Press emergency cut-off knob and remove

key switch.

¾ Remove rubber mat from floor pla

te.

¾ Remove floor plate.

¾ Clean housing of pressure filter, outside

and on upper cover.

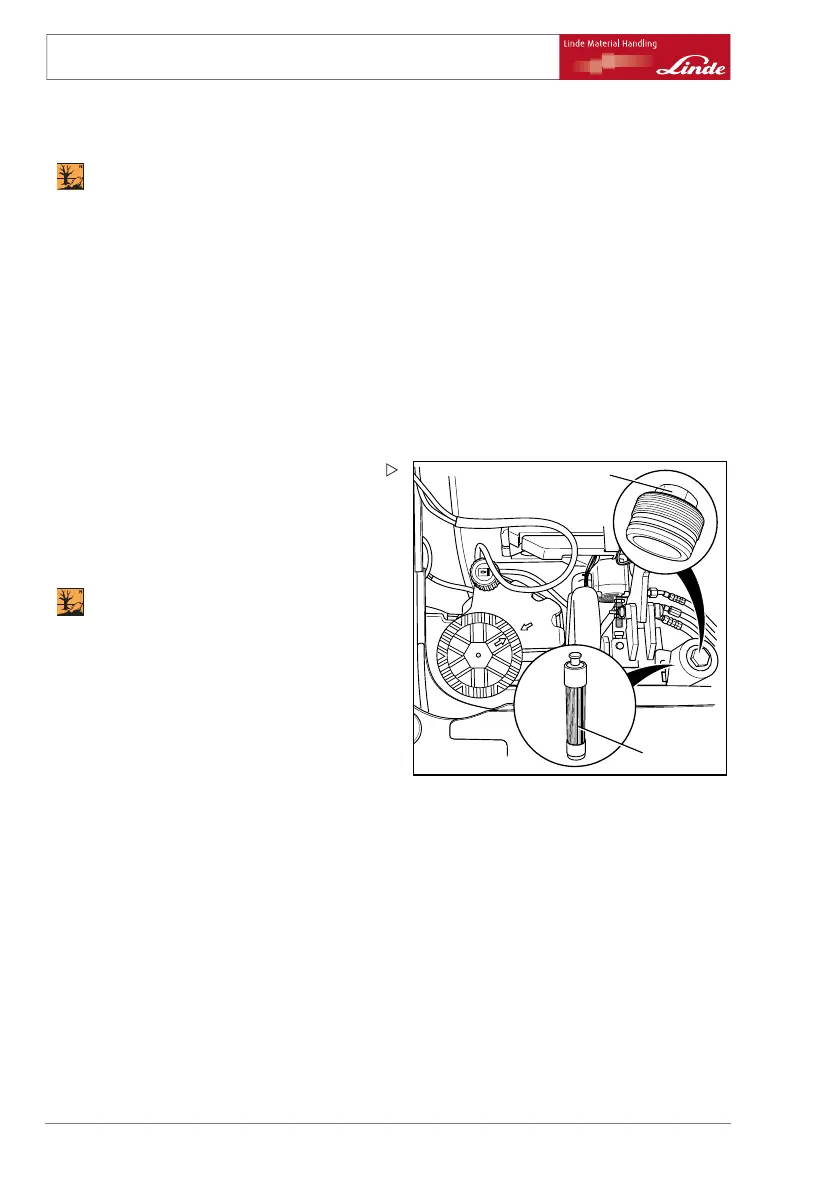

e3861376

2

1

¾ Unscrew filter cover (1) from pr

essure filter

using a socket or ring wrench.

¾ Slowly pull out filter insert (2) from filter

housing.

¾ Collect oil drips in a vessel.

ENVIRONMENT NOTE

Dispose of old filter insert and

oil in an environ-

mentally friendly manner.

¾ Fit new filter insert (2) in pressure filter.

¾ Screw filter cover (1) back onto pr

essure

filter.

Tightening torque: hand-tighten (10

+5

Nm)

and then loosen a 1/4 turn.

¾ Check pressure filter for leakage.

¾ Vent hydraulic system.

122 Operating Instructions – 386 807 1001 EN – 03/2006

Loading...

Loading...