5 Servicing

Inspection and maintenance every 3000 operating hours or every 2 years

Wheel gear oil change (with wheels

detached)

ENVIRONMENT NOTE

Take note of information about working mate-

rials.

¾ Warm up wheel gear.

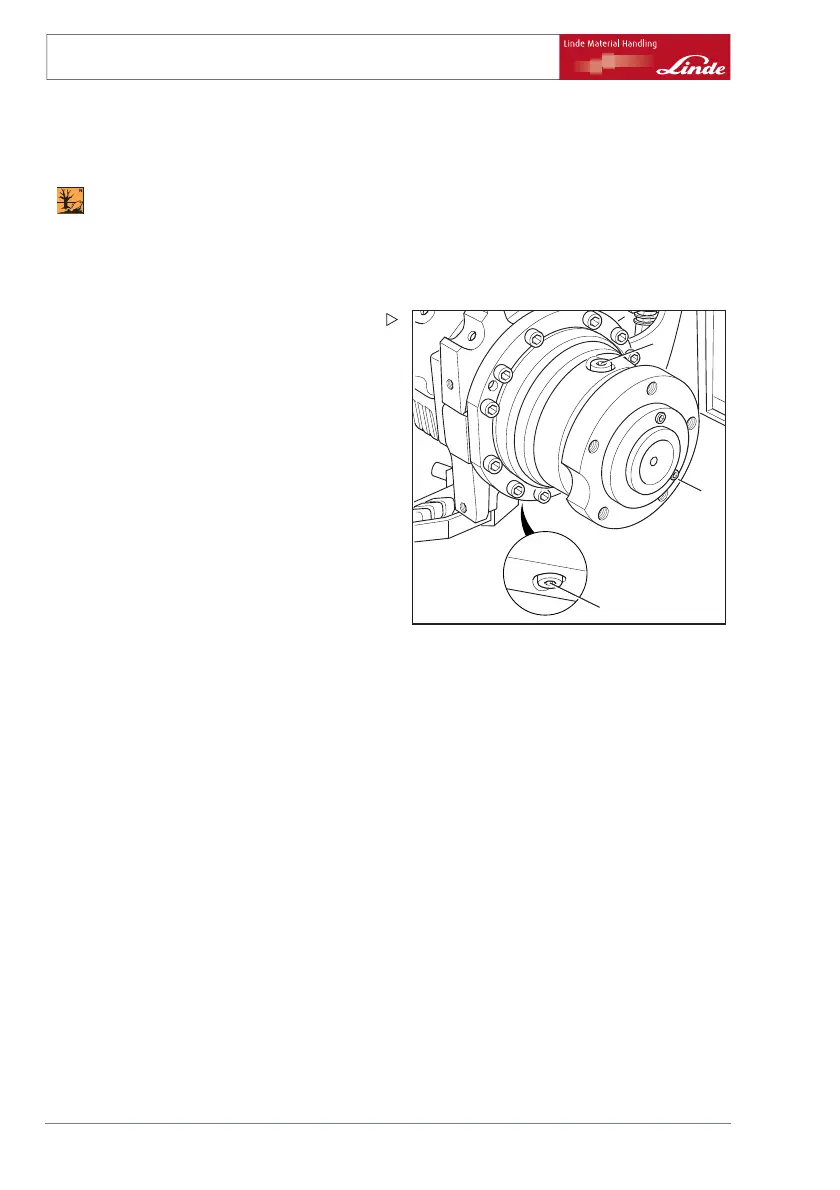

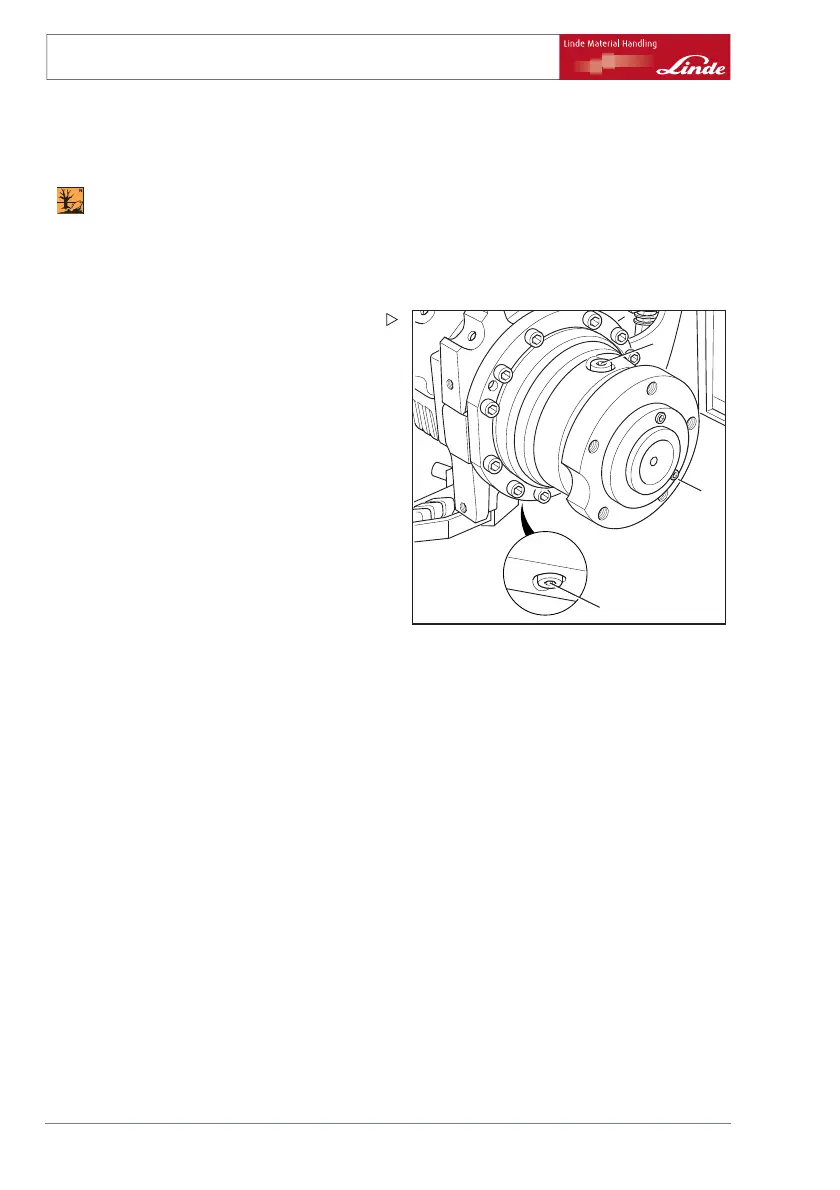

e3861305

4

1

3

¾ Stop the forklift truck so that the checking

screw (1) is at the "5 o’clock" position .

¾ Raise the forklift truck with t

he jack on the

right / left and secure.

¾ Remove drive wheel.

¾ Place a collection vessel under the drain

plug (3).

¾ Unscrew the drain plug (3), fil

ling screw (4)

and checking screw (1) and allo

wallthe

transmission oil to drain off .

¾ Clean the area around the checking screw

(1) , drain plug (3) and filling screw (4).

¾ Clean the magnetic plug of the drain

plug (3) .

¾ Screw the drain plug (3) securel

y back in.

Tightening torque 20 Nm

¾ Addapprox.250cm

3

oil per wheel gear to

the filling screw hole until oil escapes from

the screwhole of the checking screw (1).

¾ Screw the checking screw (1) and f

illing

screw (4) securely back in.

Tightening torque filling screw (4) 70 Nm

Tightening torque checking screw (1) 20 Nm

¾ Repeat on 2nd wheel.

¾ Reattach wheels and lower forklift truck

again.

130 Operating Instructions – 386 807 1001 EN – 03/2006

Loading...

Loading...