55

B751

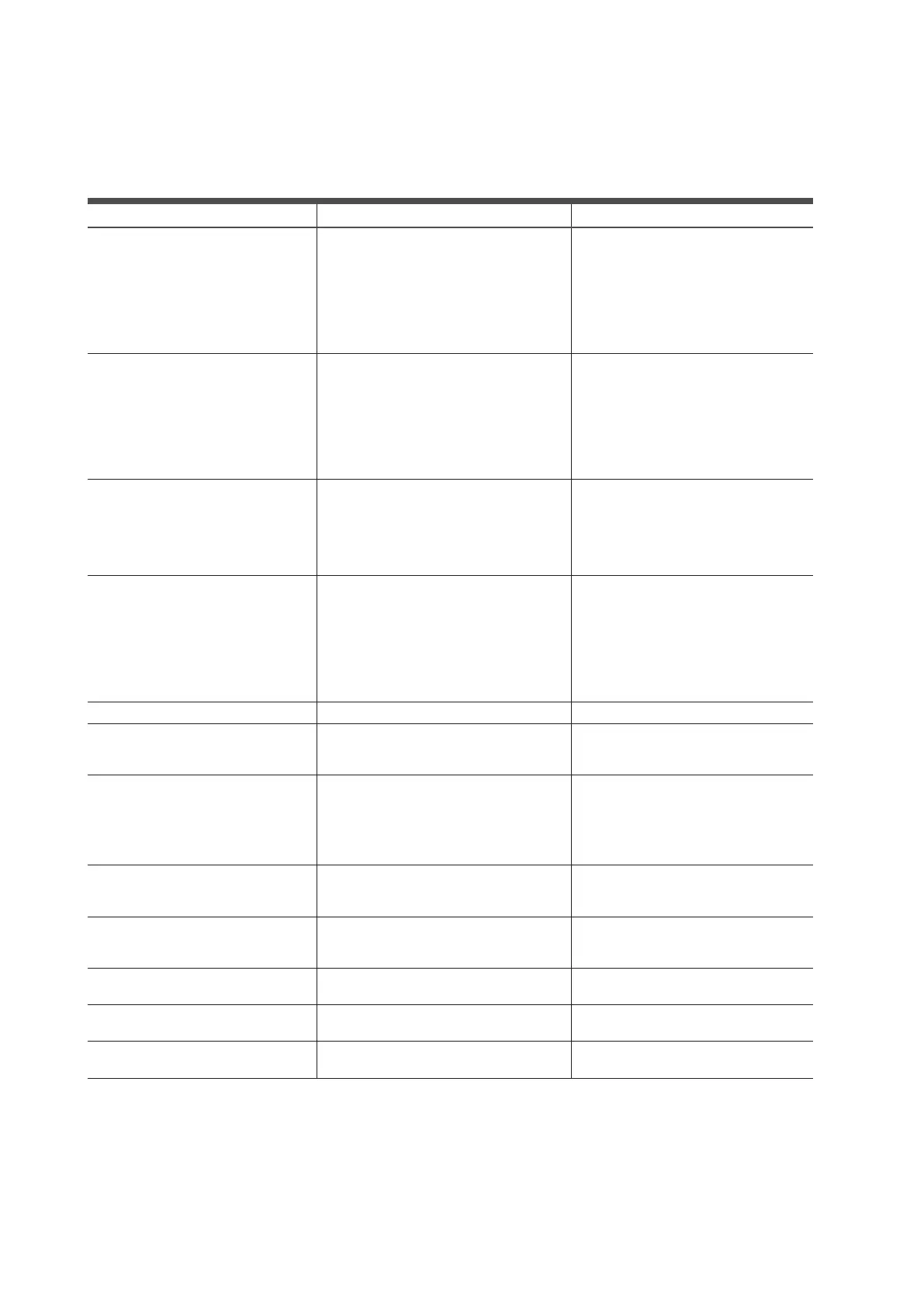

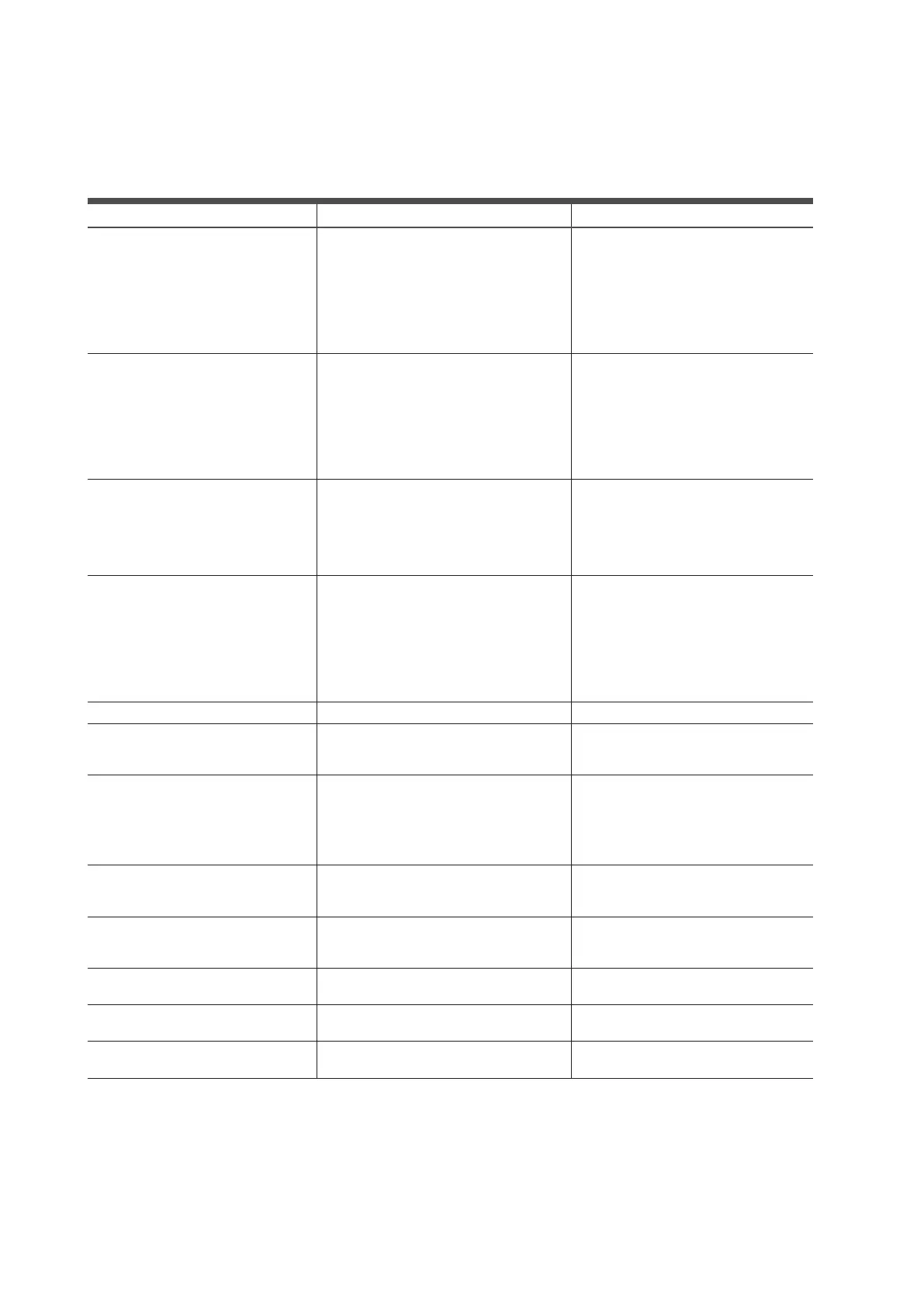

PROBLEM/SYMPTOM PROBABLE CAUSE ACTION

The saw blade quickly loses its edge • Dirty logs

• The saw blade is worn out

• Avoid dragging the logs over the ground.

• Debark the log at the point where the saw blade

is to cut

• Saw square blocks off the logs before sawing

boards to reduce the number of cuts made

through bark.

• Replace the saw blade

Crooked kerf • Blunt saw blade

• Feed rate too fast

• Feed rate too slow

• Sawing into partially frozen log

• Regrind the saw blade

• Reduce the feed rate

• Increase the feed rate

• Leave the log to thaw or become completely

frozen before sawing. TIP: Do not approach the

log tentatively; allow the blade to make contact

with the end of the log directly at an adapted

cutting speed.

The saw blade works downwards or upwards

while you saw

• Inadequate saw blade tensioning

• Feed rate too fast

• Saw blade damaged

• Saw blade not tracking properly over the

band wheels

• Increase the saw blade tension

• Reduce the feed rate

• Replace the saw blade

• Fit the saw blade correctly and adjust

the tracking

Bandsaw blade breakage • The saw blade is worn out

• Saw blade blunt and/or fitted incorrectly

• Saw blade over-tensioned

• The blade guide rollers have not been fitted to

match the band wheels

• Worn shoes on the band wheels resulting in the

bandsaw blade coming into direct contact with the

metal

• Replace the saw blade

• Regrind the saw blade

• Reduce the saw blade tension

• Adjust the blade guides

• Replace shoes on the band wheels

Uneven thickness of sawn wood • The saw bed is springy due to insufficient support • Support the rail and log bed as instructed

The saw blade does not track and backs

out of the band wheels

• Incorrect band wheel adjustment

• Worn band wheel linings

• Adjust the band wheels as instructed

• Replace the linings

The saw blade does not cut • Saw blade installed in the wrong direction • Remove the saw blade, turn it inside out and

then refit it

• When using the electric motor, check that the

motor is running in the right direction, action:

Reverse the electric motor.

The saw blade is under tension even though

the blade tension has been released using

the T-handle

• The blade tensioning mechanism is seized • Push the T-handle inwards

The saw head is hard to move up and down • The vertical guides are too narrow

• The drum of the saw head’s lifting winch needs

lubricating

• Lubricate with silicone, and loosen the guides

slightly where appropriate

• Lubricate with Superflo

The saw head rattles when it is lowered • The rail component is not flat and breaks

in the saw carriage

• Weigh down the rail component as instructed

so that it is flat

The saw blade overheats when sawing • There is no more water in the water tank

• The water valve is closed

• Top up water

• Open the water valve

The motor/engine will not start • The ignition switch is set to “OFF”

• The cover switch is enabled

• Turn the ignition switch to “ON”

• Check function

TROUBLESHOOTING SCHEDULE

Loading...

Loading...