- 34 -

FOCS Workshop Manual_cod. 1.5302.351_7° ed_ rev. 06

21

22

23

4

24

Return pulley

Remove the center bolt 1 and slide the pulley from the engine.

Components:

1 Bolt 6 Bearing

2 Washer 7 Spacer

3 Spacer 8 Bearing

4 Pulley 9 Snap Ring

5 Snap Ring

Note: On remounting thoroughly clean out the threads of screw 1

and tighten at 25 Nm.

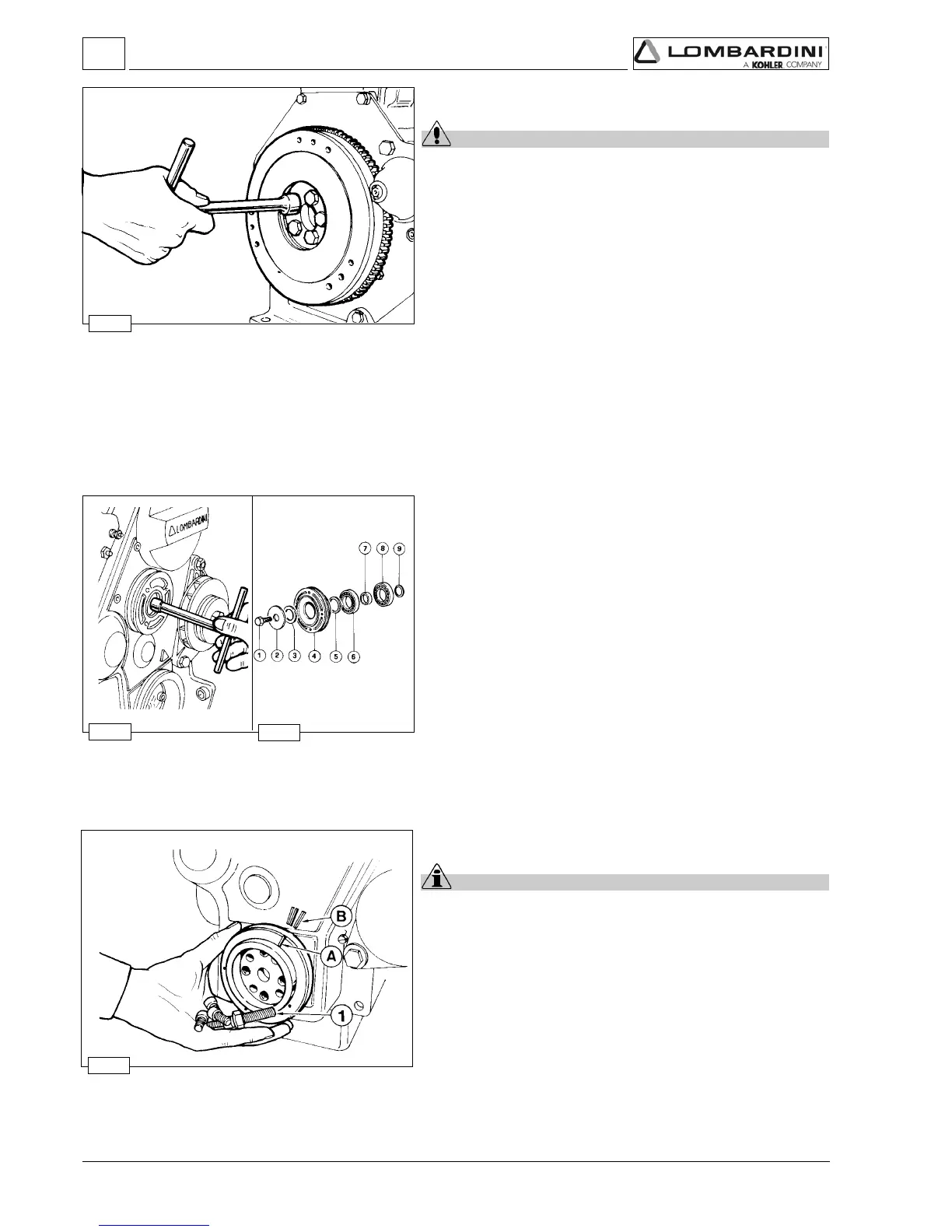

Flywheel

Danger - Attention

During dismounting be particularly careful not to let the

flywheel fall, as this can be very dangerous for the operator.

Use protective goggles while removing the starter ring gear.

Unscrew the screws that fasten it to the crankshaft.

In order to replace the ring gear, it is necessary to disassemble the

flywheel.

Cut the ring gear in several places using a chisel and remove it.

Heat the new ring gear uniformly and keep it at a temperature of

300°C for 15÷20 minutes.

Insert the ring gear into its seat and place it carefully on the rim of the

flywheel.

eave to the ring gear to cool gently before reassembling the flywheel.

When refitting tighten the screws at 80 Nm.

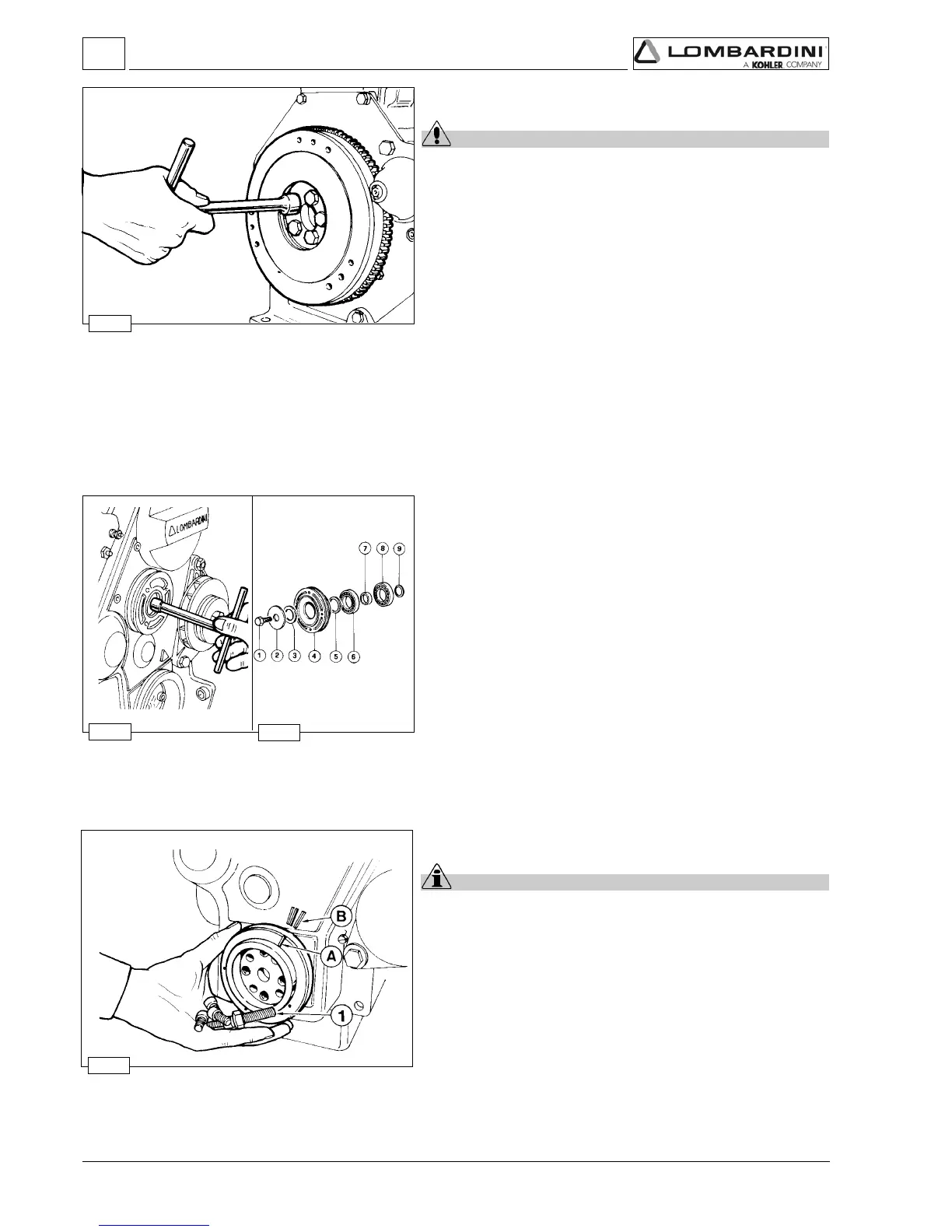

Driving pulley

Important

To loosen or screw in screw 1 at the set torque you must

always stop the crankshaft and not other parts of the engine.

Locking the crankshaft: remove the engine starter and installing the

fixture tool 1460-051.

Remove the pulley, after having unscrewed central screw 1 and

proceed with the four lateral screws.

The central bolt 1 is left-handed.

When reassembling, apply some Moly-slip antiseizure compound

on the screw thread and tighten at 360 Nm.

Note: When pulley reference mark (A) aligns with the timing cover

reference mark (B), the flywheel side piston is at TDC.

Disassembly / Reassembly

Loading...

Loading...