- 44 -

FOCS Workshop Manual_cod. 1.5302.351_7° ed_ rev. 06

59

60

62

64

61

63

4

Valve / Rocker arm clearance

Important

Setting should be performed when the engine is cold.

Bring each cylinder piston to top dead center on the compression

stroke and set clearance A at 0,20 mm for both the intake and

exhaust valves.

For greater convenience, clearance check B is accepted. In this case

the value is 0.15 mm.

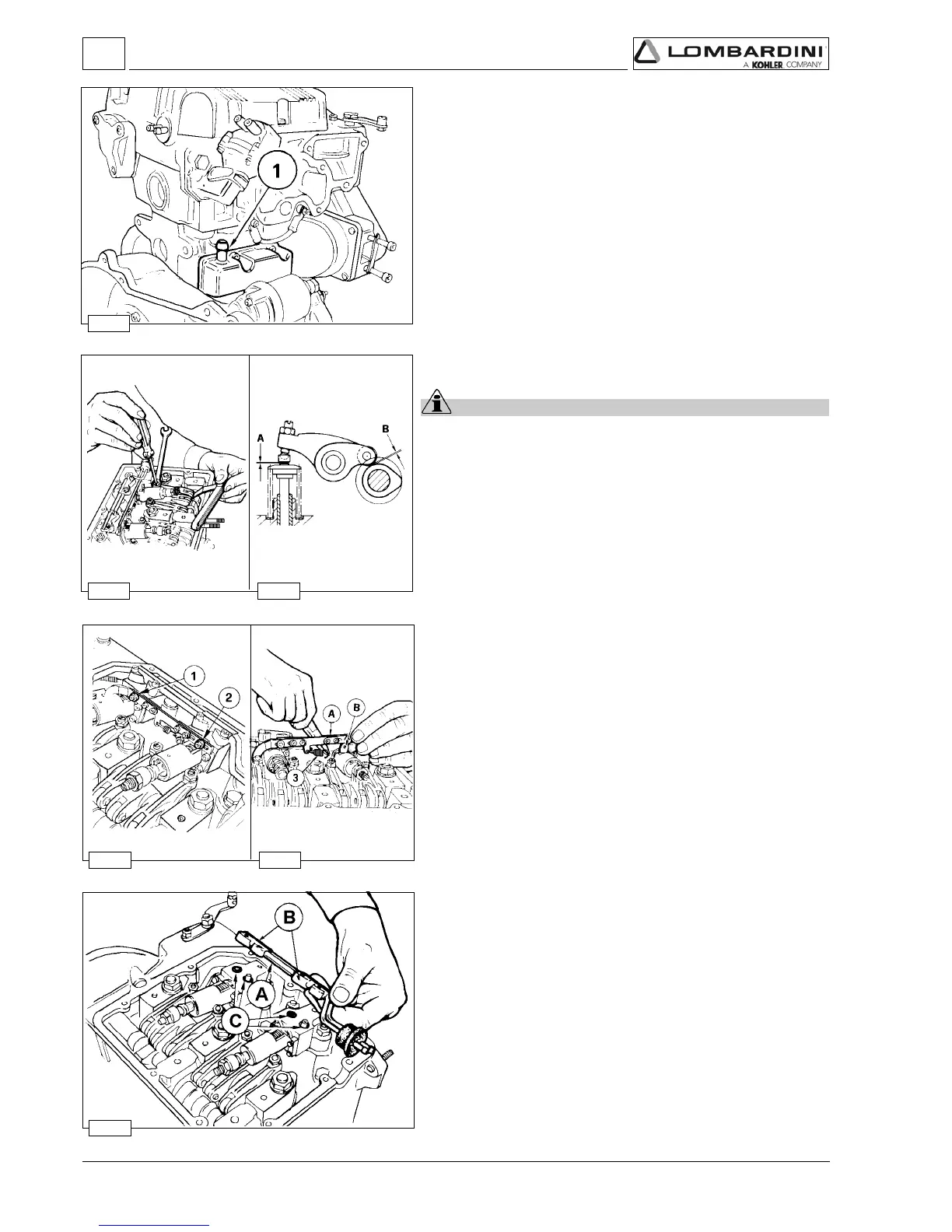

Crankcase breather LDW 502

For LDW 602-702-903-1003-1204-1204/T-1404 engines, the exhaust

gases exit from the cylinder head cover, see Fig. 53, 54.

In the LDW 502 engine the exhaust gases exit directly from the

crankcase via cover 1.

Remove the cover, check the integrity of the air valve and oil

decanting wire gauze.

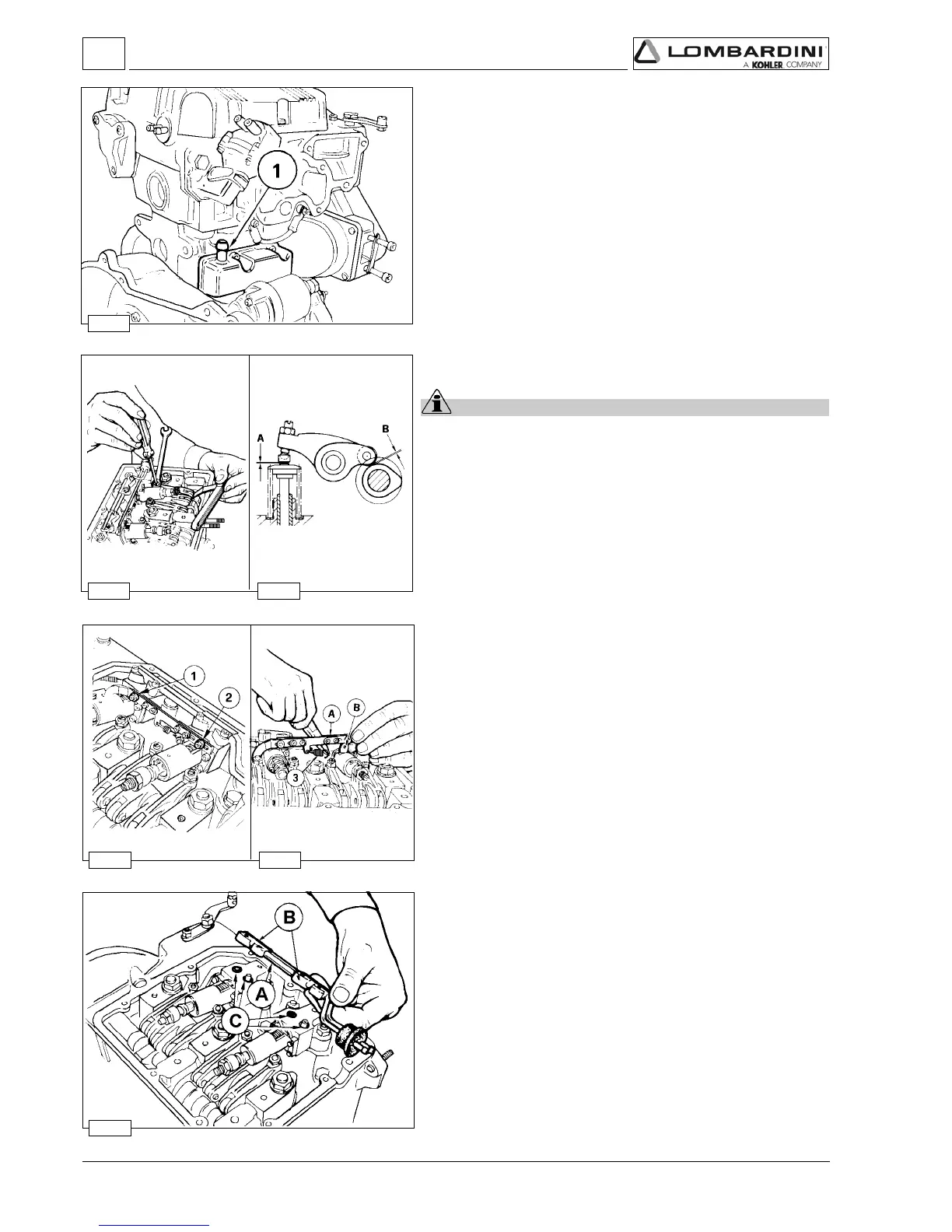

Fuel rail

When removing the fuel feeding pumps A, with the rail holders B,

pay attention that the sealing O-rings C remain in their seats.

When refitting tighten the rail holder screws at a torque of 4 Nm.

Injection pump control rod

Depending on the engine model, the injection pump control rod will

link two, three, or four injectors to the engine governor.

Screws 1 and 2 are pivoted on the delivery control lever of each

pump/injector B, unscrew the screws and remove spring 3.

When refitting tighten the screws 1 and 2 at a torque of 1,1 Nm

and make sure that they stop on lever B of each pump/injector and

not on rod A.

To carry out the delivery equalisation of the injection pumps see

page 83.

To carry out the timing of the injection pumps and speed

governor see page 95

Disassembly / Reassembly

Loading...

Loading...