- 58 -

FOCS Workshop Manual_cod. 1.5302.351_7° ed_ rev. 06

116

117

119

118

4

CONNECTING ROD

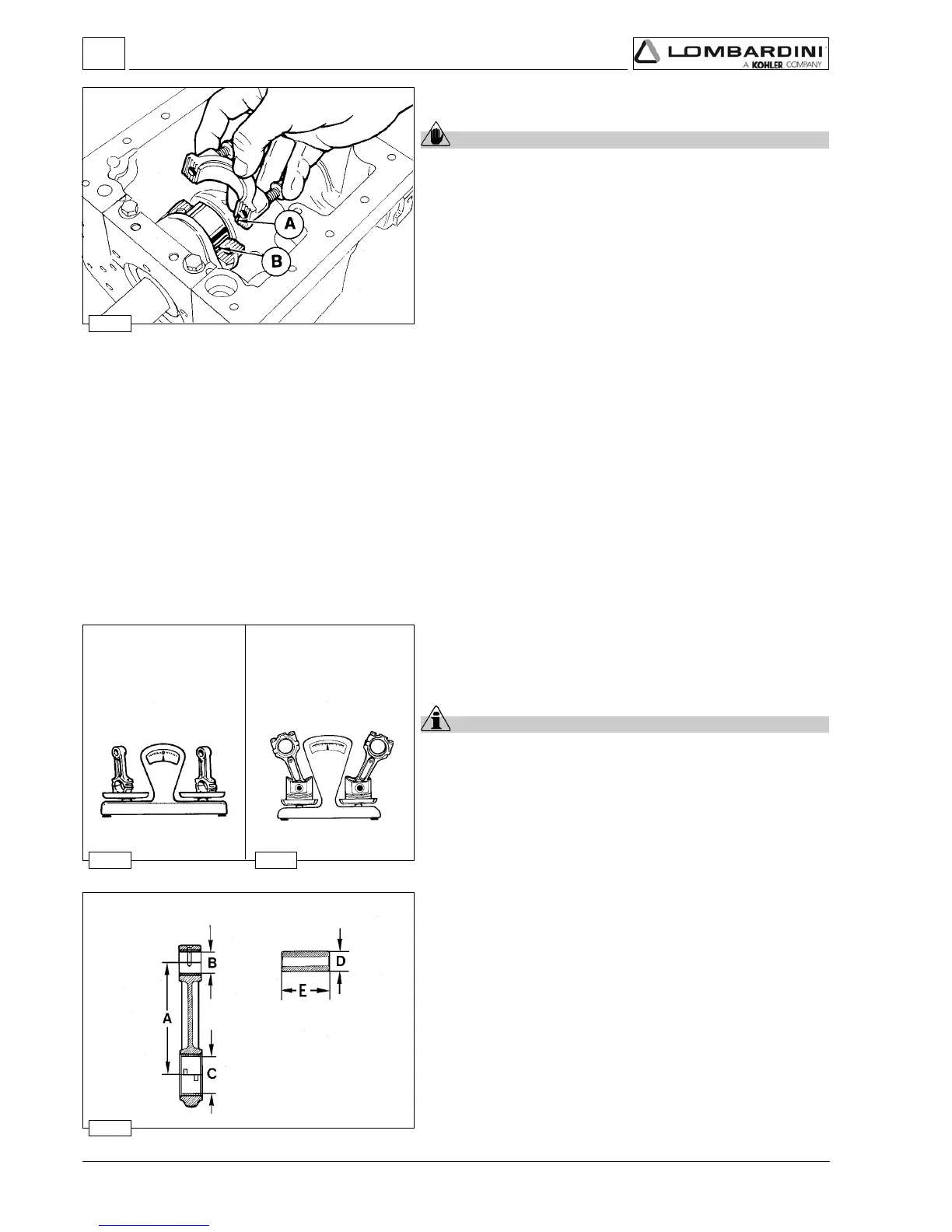

Caution – Warning

While reassembling the big end bearings, we suggest cleaning

all parts thoroughly, as well as proper greasing in order to

avoid risks of seizure at the first start.

Big end bearing

After connecting rod from crankshaft disconnection, check the

following.

While reassembling, be sure the two centring notches A an B are

on the same side.

Tighten the connecting rod big end cap screws simultaneously at

a torque of 40 Nm.

Note: The big end bearing is supplied both at the nominal value

and undersized by 0.25 and 0.50 mm.

In the LDW 502 engine with light alloy crankcase the

connecting rod is aluminium type and not provided with

connecting rod big end bearing and small end bush.

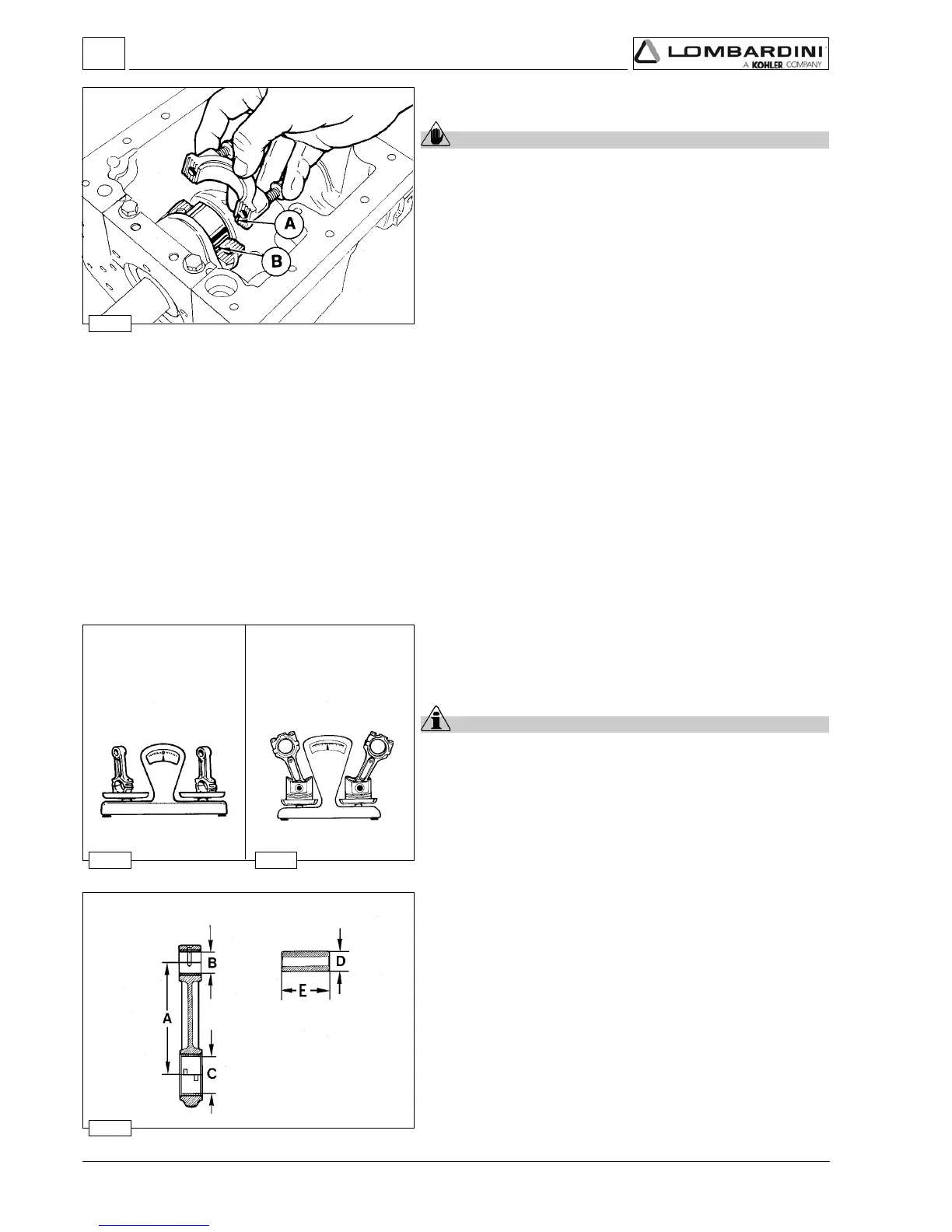

Connecting rod with bearings and pin

Dimensions (mm):

A =126,48÷126,52

=106,98÷107,02..... (for LDW 502)

B =18,015÷18,025

=20,015÷20,025..... (for LDW 702-1003-1204/T-1404)

C =40,021÷40,050..... (bearing tightened at 40 Nm)

D =17,996÷18,000

=19,996÷20,000..... (for LDW 702-1003-1204/T-1404)

E =50,900÷51,100

=54,000÷55,100..... (for LDW 702-1003-1204/T-1404)

(B-D) = 0,015÷0,039 (B-D) limit value = 0,060

Nota: When driving the small end bearing make sure both oilholes

are aligned.

Connecting tod, weight

Weigh connecting rods when replacing them in order to avoid

unbalance.

Important

The difference in weight should not exceed 10 g.

The difference in weight of the pre-assembled connecting rod, piston

and pin must not exceed 14 g.

Disassembly / Reassembly

Loading...

Loading...