- 57 -

FOCS Workshop Manual_cod. 1.5302.351_7° ed_ rev. 06

4

113

114

115

Cylinder head assembly

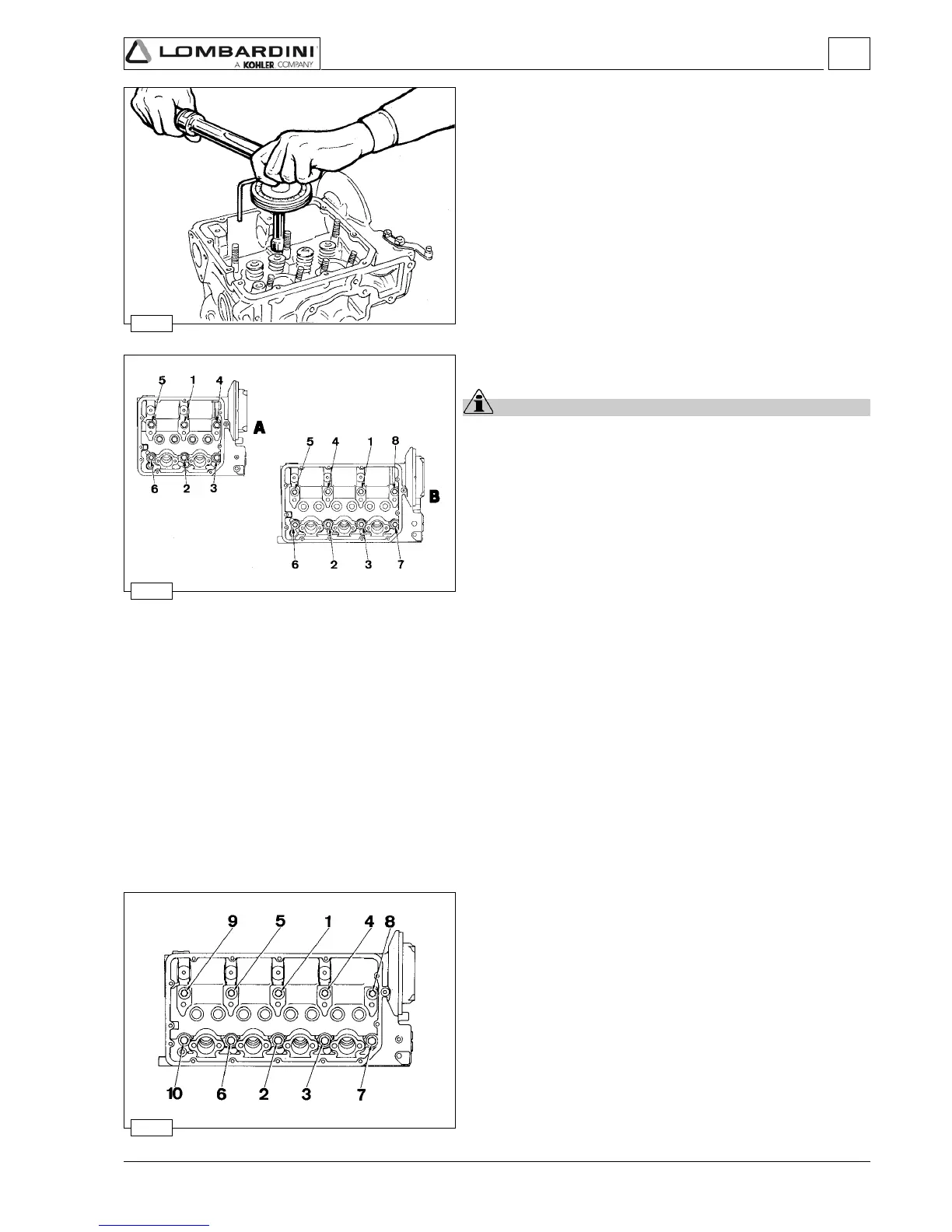

Use a torque wrench equipped with a device for angular tightening.

Measure the length of each screw (normal length = 89.5÷90.5 mm).

Replace it if it exceeds 92 mm.

Proceed as follows.

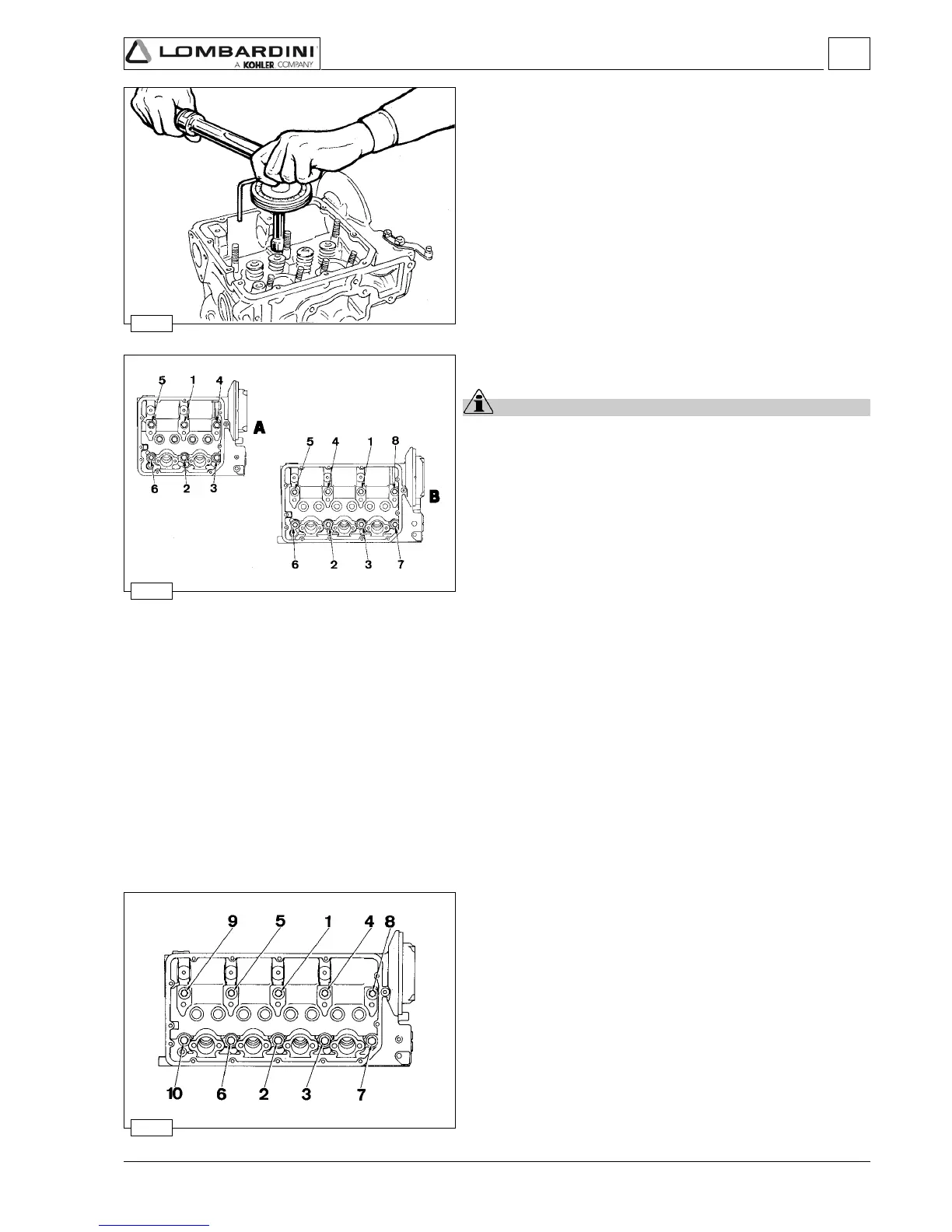

Cylinder head tightening procedure LDW 1204-1204/T-1404

Following the numerical order shown in the diagram, the bolts must

be tightened in three phases:

1

st

phase = 50 Nm

2

nd

phase = Rotate the wrench 90° in a clockwise direction.

3

rd

phase = Rotate the wrench again 90° in a clockwise direction.

Cylinder head tightening procedure LDW 502-602-702-903-1003

Important

Once the head has been correctly tightened, it should not be

retightened except if it is disassembled again.

Before mounting it is advisable to lubricate stem, shank and

underhead of screws with SPARTAN SAE 460 oil.

A = For LDW 502-602-702 models

B = For LDW 903-1003 models

Following the numerical order shown in the diagram, the bolts must

be tightened in three phases:

1

st

phase = 50 Nm

2

nd

phase = Rotate the wrench 90° in a clockwise direction.

3

rd

phase = Rotate the wrench again 90° in a clockwise direction.

For LDW 502 with pressure cast (aluminium) crankcase:

With head H tightening bolts: 1

st

phase = 60 Nm

With head 8.8 tightening bolts: 1

st

phase = 40 Nm

2

nd

phase = Eseguire una rotazione

della chiave in senso

orario di 90°.

3

rd

phase = Proseguire con una

rotazione della chiave in

senso orario di 90°.

Disassembly / Reassembly

Loading...

Loading...