- 95 -

FOCS Workshop Manual_cod. 1.5302.351_7° ed_ rev. 06

220 221

222

223

10

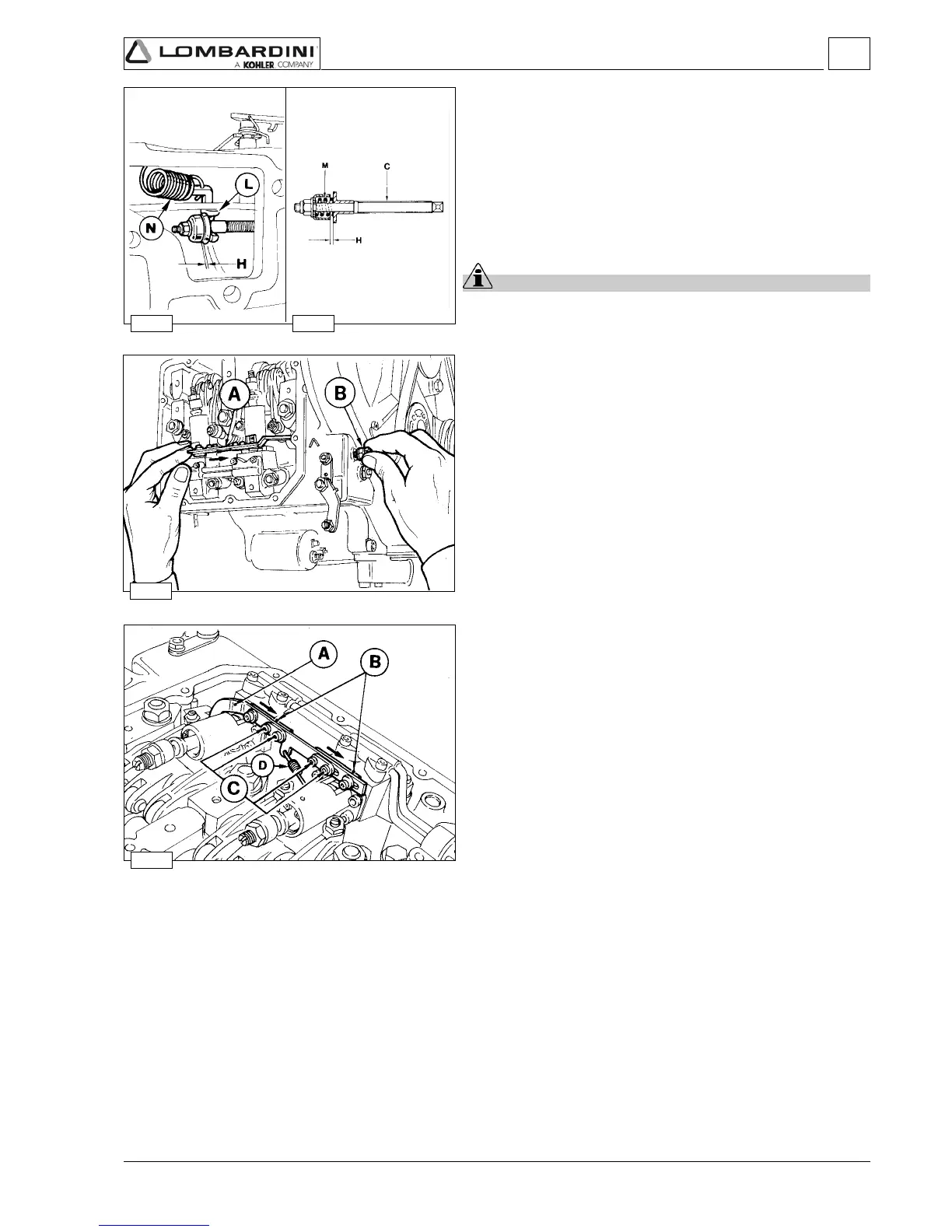

Setting the stop

Remove the rocker arms cover and completely unloosen screw B.

Push rod A to the right and keep it in this position; see figure.

Tighten screw B until it touches rod A.

Release rod A and tighten again screw B by a 0.5÷1.0 turn.

Tighten the lock nut.

Pump/injector unit timing with speed governor

-Loosen the screws C of each pump/injector unit.

-If it is not connected, connect spring D to rod A (with this

operation the speed governor blocks are closed).

-Move plates B of each pump/injector unit rightwards; see figure

(with this operation the pumps/injector unit are at their maximum

delivery).

-Tighten screws C at 1.1 Nm. Re-balance the deliveries.

Note: Spring D is the start-up fuel supplement spring: with the

engine stopped pull rod A to the right by bringing the pump/

injector unit delivery to the maximum value, until the speed

governor comes into operation with the engine running

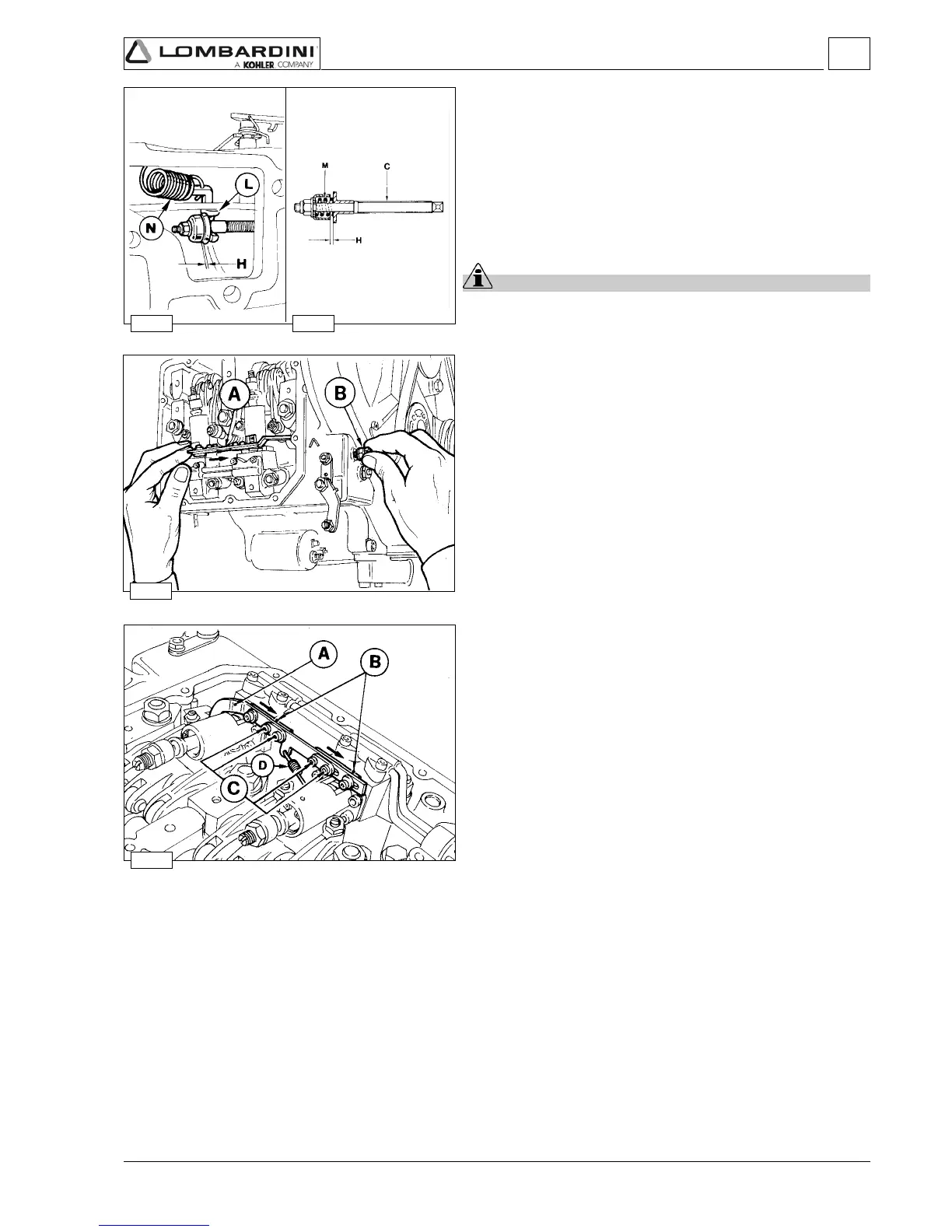

Injection pump flow limiter and engine torque gearing device

Flow limiter C has the function of limiting the injection pump’s

maximum delivery.

The same mechanism acts also as a torque gearing device.

Indeed, under torque, spring N operating lever L overcomes the

resistance of spring M located in the plunger barrel.

The stroke H that the torque gearing device allows to be carried out

by lever L, will increase the injection pump delivery and the torque

will hit its maximum value.

Important

The stroke H varies depending on which engine torque gearing

device is fitted on the engine.

Settings

Loading...

Loading...