REMOTE CONTROL

VALVE

The remote control valve allows the operatorto operate

a remote hydraulic cylinder.

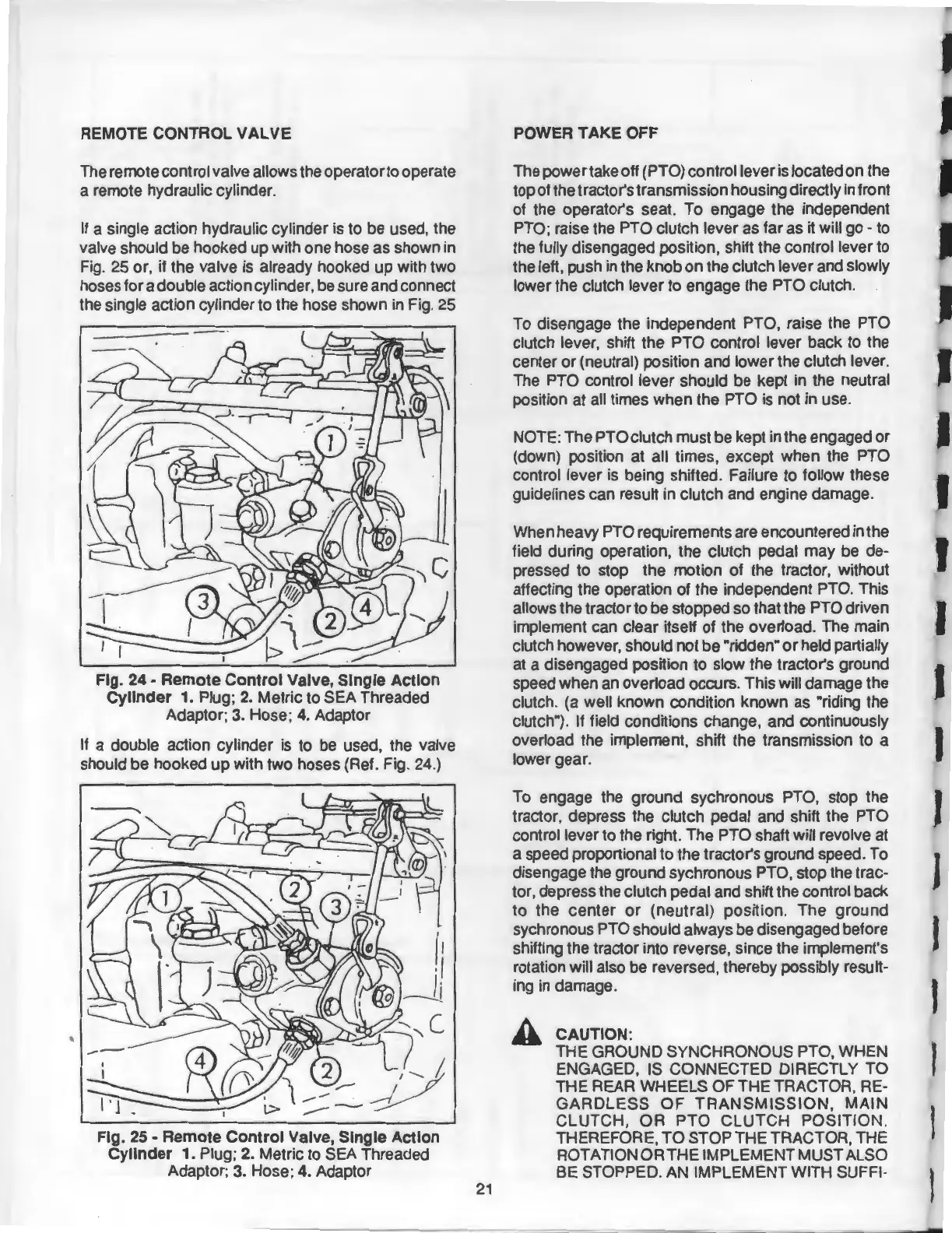

If

a single action hydraulic cylinder

is

to be used, the

valve should be hooked up with one hose as shown

in

Fig.

25

or, if the valve is already hooked up with two

hoses for a double action cylinder, be sure and connect

the single action cylinder to the hose shown

in

Fig.

25

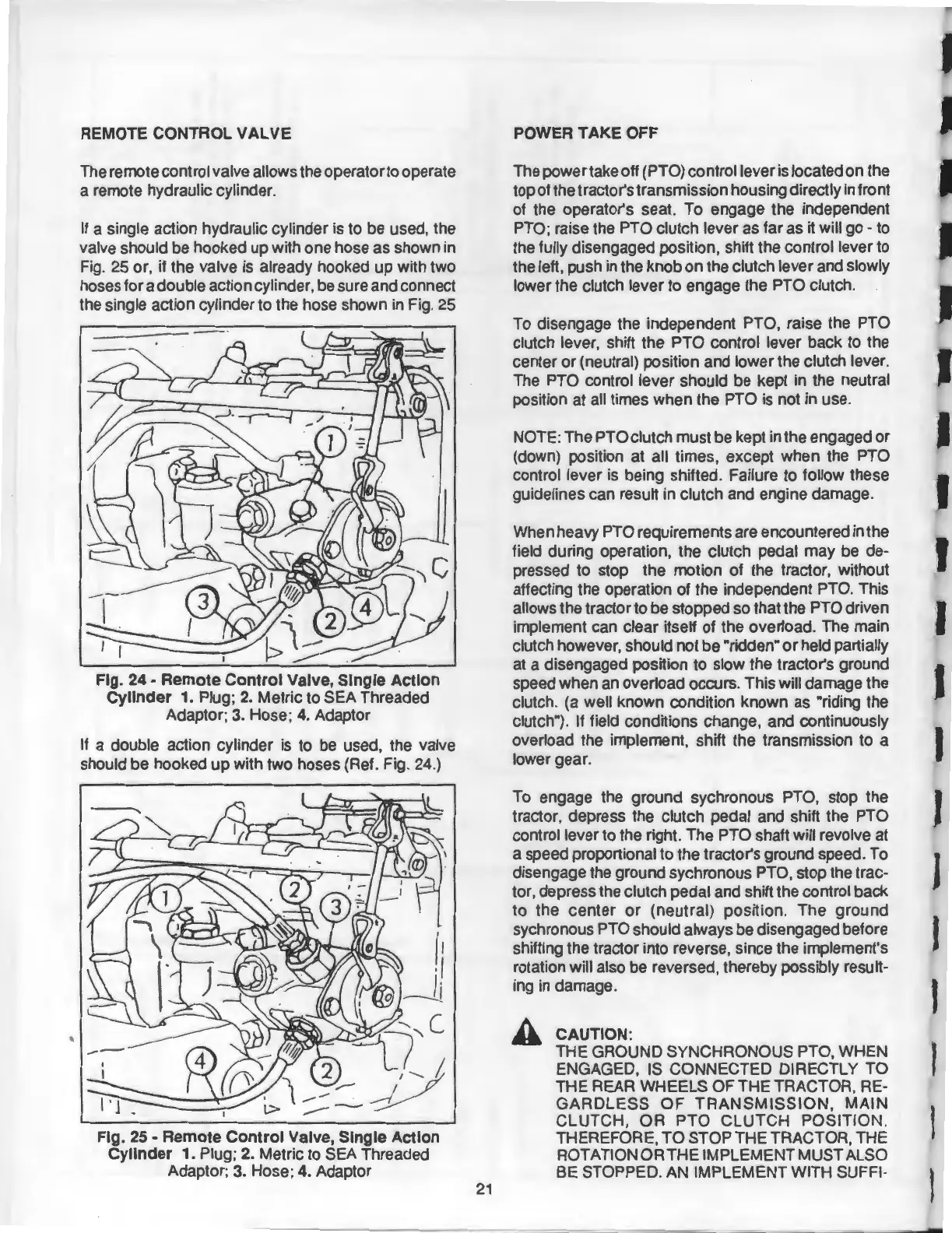

Fig. 24 -

Remote

Control

Valve,

Single

Action

Cylinder

1. Plug; 2. Metric to SEA Threaded

Adaptor; 3. Hose; 4. Adaptor

If

a double action cylinder is to be used, the valve

should be hooked

up

with two hoses (Ref. Fig. 24.)

Fig.

25-

Remote

Control

Valve, Single

Action

Cylinder

1. Plug;

2.

Metric to SEA Threaded

Adaptor; 3. Hose; 4. Adaptor

21

POWER

TAKE

OFF

The power take off ( PTO) control lever is located on the

top of the tractor's transmission housing directly

in

front

of the operator's seat. To engage the independent

PTO; raise the PTO clutch lever as far as it will

go-

to

the fully disengaged position, shift the control lever to

the left, push

in

the knob on the clutch lever and slowly

lower the clutch lever to engage the PTO clutch.

To

disengage the independent PTO, raise the PTO

clutch lever, shift the PTO control lever back to the

center or (neutral) position and lower the clutch lever.

The PTO control lever should be kept in the neutral

position at all times when the PTO is not in use.

NOTE: The PTO clutch must be kept

in

the engaged or

(down) position at all times, except when the PTO

control lever

is

being shifted. Failure to follow these

guidelines can result in clutch and engine damage.

When heavy PTO requirements are encountered

in

the

field during operation, the clutch pedal may be de-

pressed to stop the motion of the tractor, without

affecting the operation of the independent PTO. This

allows the tractor to be stopped so that the PTO driven

implement can clear itself of the overload. The main

clutch however, should not be "ridden"

or

held partially

at

a disengaged position to slow the tractor's ground

speed when an overload occurs. This will damage the

clutch. (a well known condition known as "riding the

clutch").

If

field conditions change, and continuously

overload the implement, shift the transmission to a

lower gear.

To

engage the ground sychronous PTO, stop the

tractor, depress the clutch pedal and shift the PTO

control lever to the right. The PTO shaft will revolve at

a speed proportional to the tractor's ground speed. To

disengage the ground sychronous PTO, stop the trac-

tor, depress the clutch pedal and shift the control back

to the center

or

(neutral) position. The ground

sychronous PTO should always be disengaged before

shifting the tractor into reverse, since the implement's

rotation will also be reversed, thereby possibly result-

ing

in

damage.

CAUTION:

THE GROUND SYNCHRONOUS PTO, WHEN

ENGAGED,

IS

CONNECTED DIRECTLY TO

THE REAR WHEELS OF THE TRACTOR, RE-

GARDLESS

OF

TRANSMISSION,

MAIN

CLUTCH,

OR

PTO

CLUTCH

POSITION

.

THEREFORE, TO STOP THE TRACTOR, THE

ROTATION OR THE IMPLEMENT MUST ALSO

BE STOPPED. AN IMPLEMENT WITH SUFFI-

J

I

J

l

J

Loading...

Loading...