1.

When installing the battery, make sure that the

ground polarity of the alternator and the ground

polarity of the battery are the same.

If

a battery of

the wrong polarity

is

installed, or the battery cables

are connected backwards, the battery is shorted

directly through the alternator's diodes. The diodes

and wiring could be damaged by the resulting high

current.

2.

When connecting a booster battery

or

auxiliary

power source, make sure to connect the positive

terminals together and the negative terminal on the

booster source to a good ground (i.e. chassis or

engine block support) away from the discharged

battery. Connect the negative terminal of the dis-

charged battery to the ground.

3.

When connecting a charger to the battery, connect

the positive charger lead to the positive battery

terminal and the negative lead to the negative

terminal. Failure to do so will result in alternator

and wiring damage. Never attempt to start the

engine

or

turn the ignition switch "ON" while the

charger is in use.

4. Never short across

or

ground any terminals on the

alternator

or

regulator. Grounding

or

shorting any

of the terminals can cause serious electrical mal-

functions that can damage components in the

electrical system.

5.

Do

not attempt to polarize the alternator. This

procedure

is

not necessary with an alternator.

It

is

important that the battery and the alternator ground

be of the same polarity for diode protection

CAUTION:

NEVER OPERATE THE ALTERNATOR WITH

AMPATURE WIRES DISCONNECTED. WITH

NO ELECTRICAL LOAD

IN

THE CIRCUIT,

(WIRES REMOVED OR DISCONNECTED)

THE ALTERNATOR CAN BUILD UP HIGH

VOLT AGE, WHICH CAN BE EXTREMELY DAN-

GEROUS TO ANYONE WHO MIGHT ACCI-

DENTALLY TOUCH THE BATTERY TERMI-

NALS OR ALTERNATOR. BEFORE MAKING

ANY CHECKS OR TEST, MAKE SURE THAT

ALL CONNECTIONS IN THE CIRCUIT ARE

TIGHT AND SECURE.

LUBRICATION

LUBRICATION

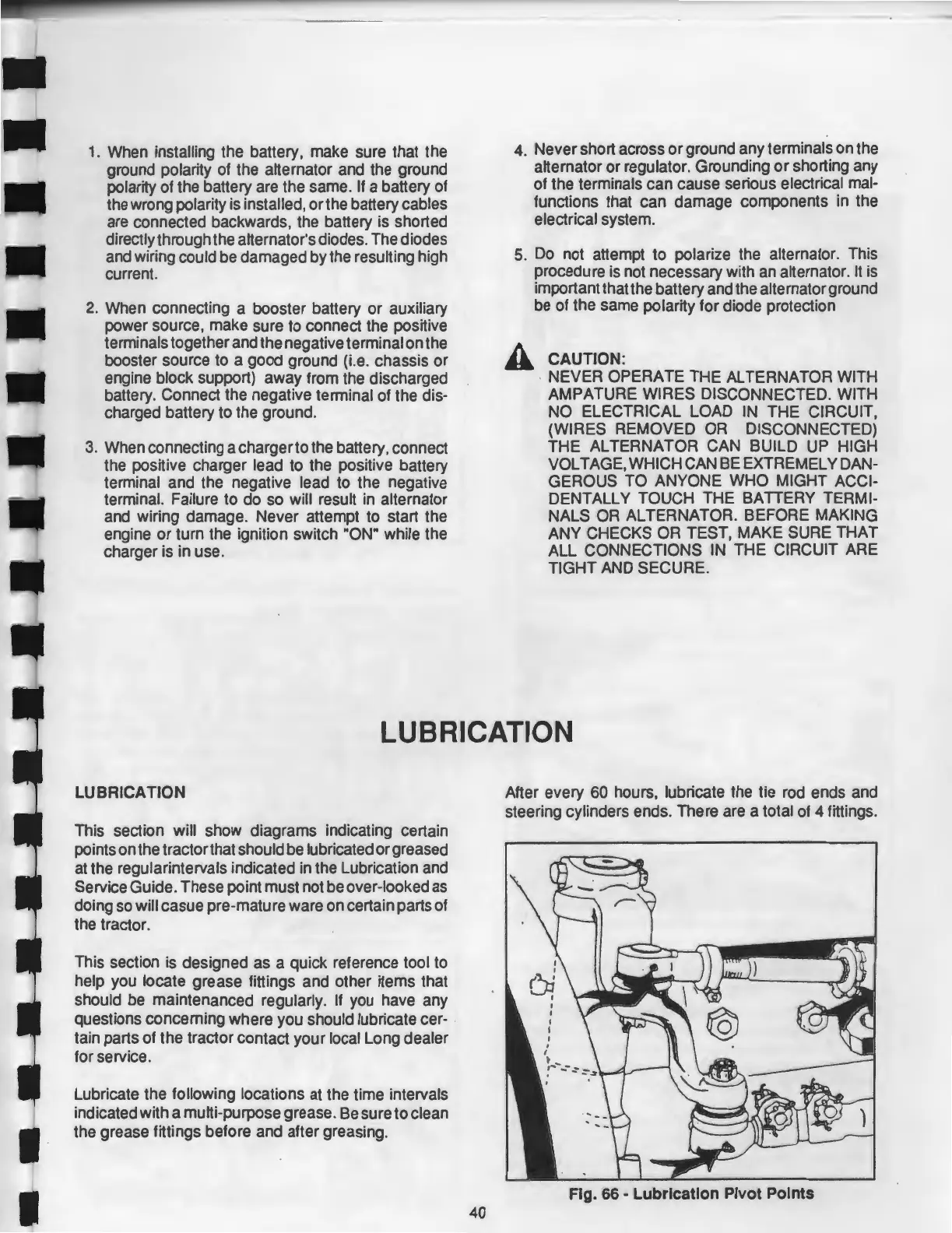

This section will show diagrams indicating certain

points on the tractor that should be lubricated or greased

at the regularintervals indicated in the Lubrication and

Service Guide. These point must not be over-looked

as

doing

so

will casue pre-mature ware on certain parts

of

the tractor.

This section is designed as a quick reference tool to

help you locate grease fittings and other items that

should be maintenanced regularly.

If

you have any

questions concerning where you should lubricate cer-

tain parts of the tractor contact your local Long dealer

for service.

Lubricate the following locations at the time intervals

indicated with a multi-purpose grease.

Be

sure to clean

the grease fittings before and after greasing.

40

After every 60 hours, lubricate the tie rod ends and

steering cylinders ends. There are a total of 4 fittings.

Fig. 66 - Lubrication Pivot Points

Loading...

Loading...