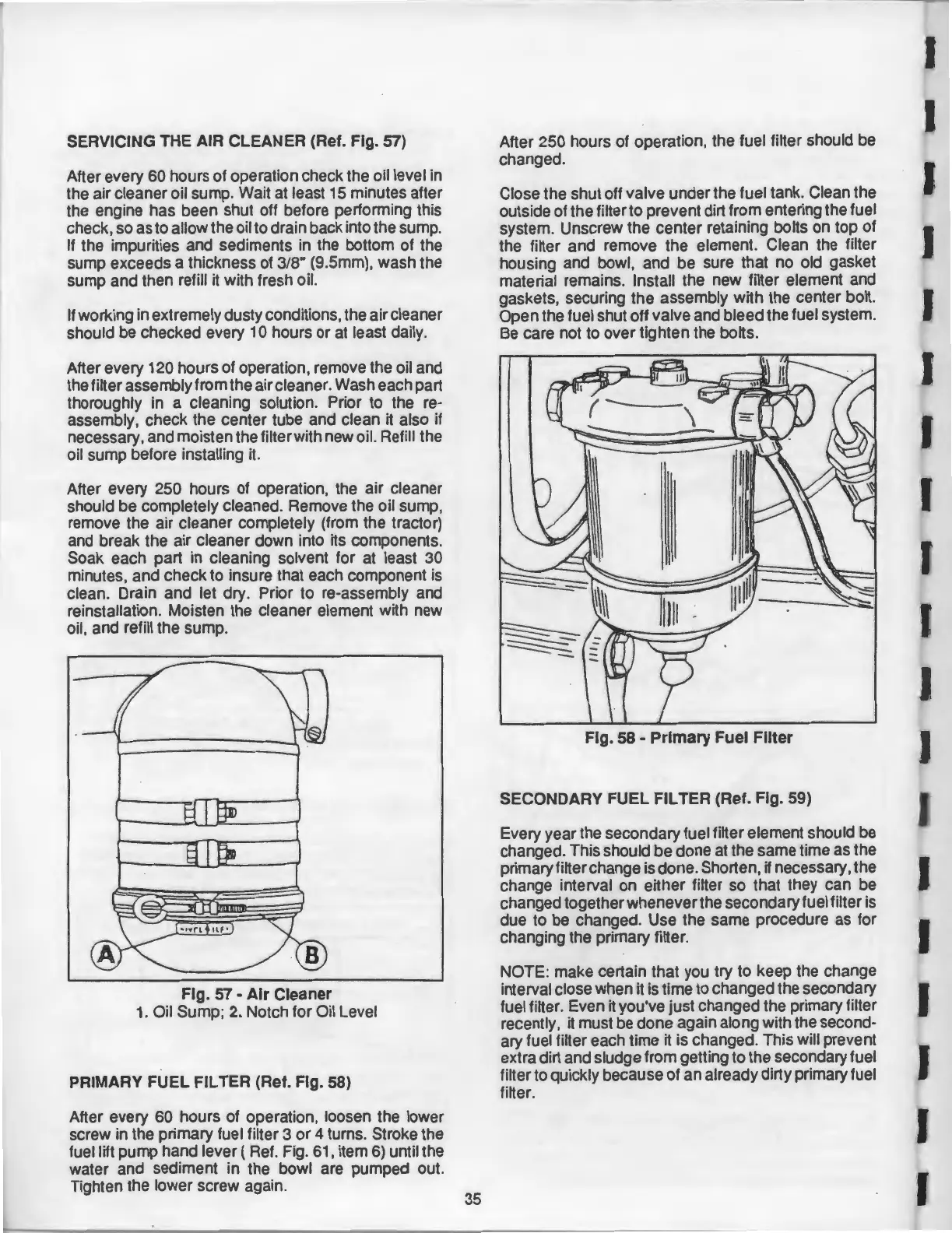

SERVICING THE AIR CLEANER (Ref.

Fig.

57)

After every 60 hours of operation check the oil level in

the air cleaner oil sump. Wait at least 15 minutes after

the engine has been shut off before performing this

check, so as to allow the oil to drain back into the sump.

If the impurities and sediments in the bottom of the

sump exceeds a thickness of 3/8" (9.5mm), wash the

sump and then refill

it

with fresh oil.

If working in extremely dusty conditions, the air cleaner

should be checked every 1 0 hours

or

at least daily.

After every 120 hours of operation, remove the oil and

the filter assembly from the air cleaner. Wash each part

thoroughly in a cleaning solution. Prior to the re-

assembly, check the center tube and clean it also if

necessary, and moisten the filter with new oil. Refill the

oil sump before installing it.

After every 250 hours of operation, the air cleaner

should be completely cleaned. Remove the oil sump,

remove the air cleaner completely (from the tractor)

and break the air cleaner down into its components.

Soak each part in cleaning solvent for at least 30

minutes, and check to insure that each component

is

clean. Drain and let dry. Prior to re-assembly and

reinstallation. Moisten the cleaner element with new

oil, and refill the sump.

Fig. 57 •

Air

Cleaner

1. Oil Sump; 2. Notch for Oil Level

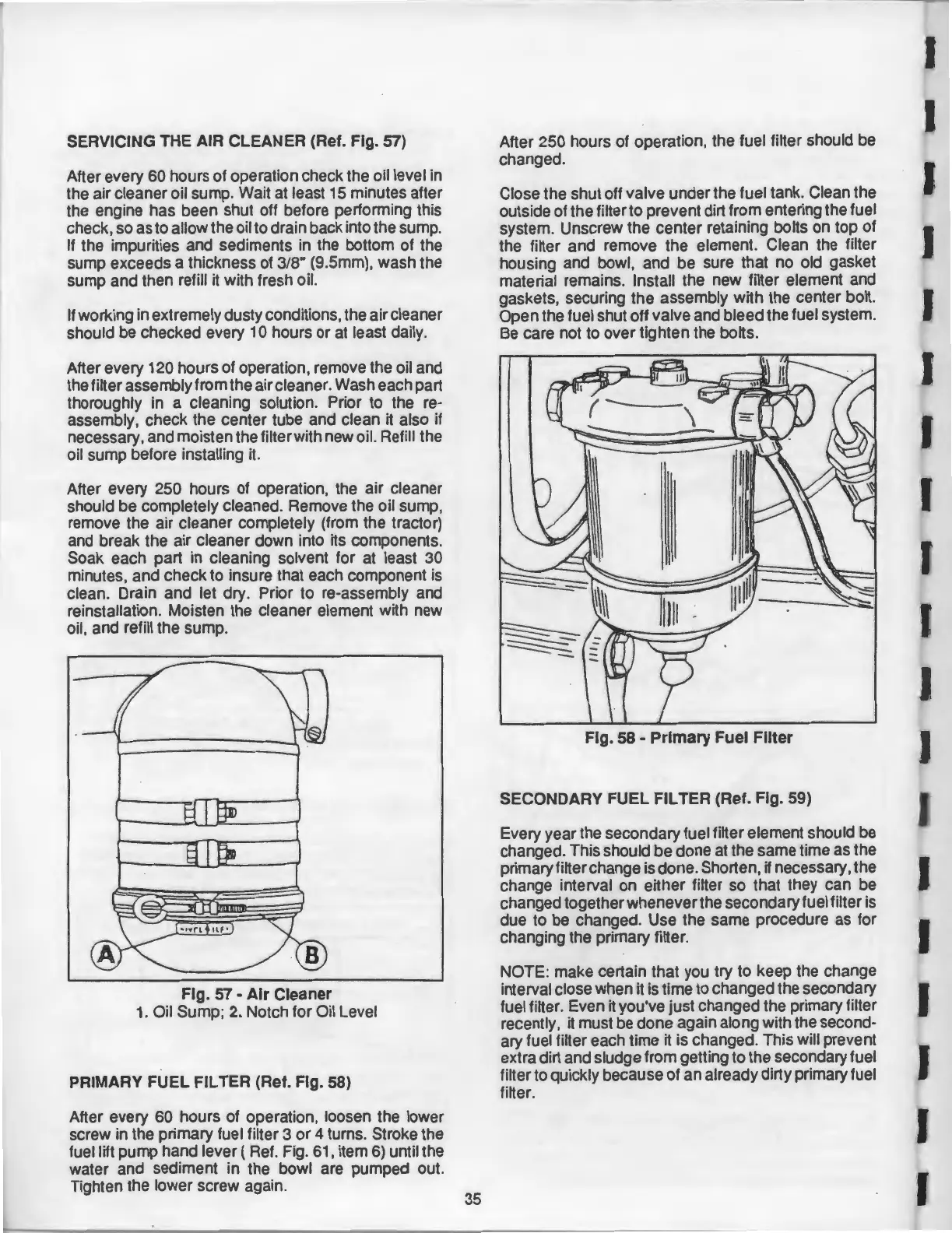

PRIMARY

FUEL

FILTER (Ref. Fig. 58)

After every 60 hours of operation, loosen the lower

screw in the primary fuel filter 3 or

4 turns. Stroke the

fuel lift pump hand lever ( Ref. Fig. 61, item 6) until the

water and sediment in the bowl are pumped out.

Tighten the lower screw again.

35

After 250 hours of operation, the fuel filter should be

changed.

Close the shut off valve under the fuel tank. Clean the

outside of the filter

to

prevent dirt from entering the fuel

system. Unscrew the center retaining bolts on top of

the filter and remove the element. Clean the filter

housing and bowl, and be sure that no old gasket

material remains. Install the new filter element and

gaskets, securing the assembly with the center bolt.

Open the fuel shut off valve and bleed the fuel system.

Be care not to over tighten the bolts.

Fig. 58 •

Primary

Fuel

Filter

SECONDARY

FUEL

FILTER (Ref. Fig. 59)

Every year the secondary fuel filter element should be

changed. This should

be

done at the same time as the

primary filter change is done. Shorten,

if

necessary, the

change interval on either filter so that they can be

changed together whenever the secondary fuel filter is

due to be changed. Use the same procedure as for

changing the primary filter.

NOTE: make certain that you try

to

keep the change

interval close when it is time to changed the secondary

fuel filter. Even it you've just changed the primary filter

recently, it must be done again along with the second-

ary fuel filter each time it is changed. This will prevent

extra dirt and sludge from getting

to

the secondary fuel

filter to quickly because

of

an already dirty primary fuel

filter.

Loading...

Loading...