CIENT ROTATIONAL INTERIA CAN OVER-

POWER THE TRACTOR'S BRAKES, MAKING

IT IMPOSSIBLE

TO

STOP THE TRACTOR

QUICKLY. THIS CAN LEAD

TO

AN ACCIDENT,

POSSIBLY CAUSING INJURY OR DEATH. TO

PROTECT

AGAINST

SUCH

AN

OCCUR-

RENCE, MAKE SURE THAT ANY IMPLEMENT

USED WITH THE GROUND SYNCHRONOUS

PTO IS DESIGNED FOR SUCH USE AND

IS

EQUIPPED WITH AN OVER-RUNNING (ONE-

WAY) CLUTCH OR OTHER SUITABLE SAFETY

DEVICE.

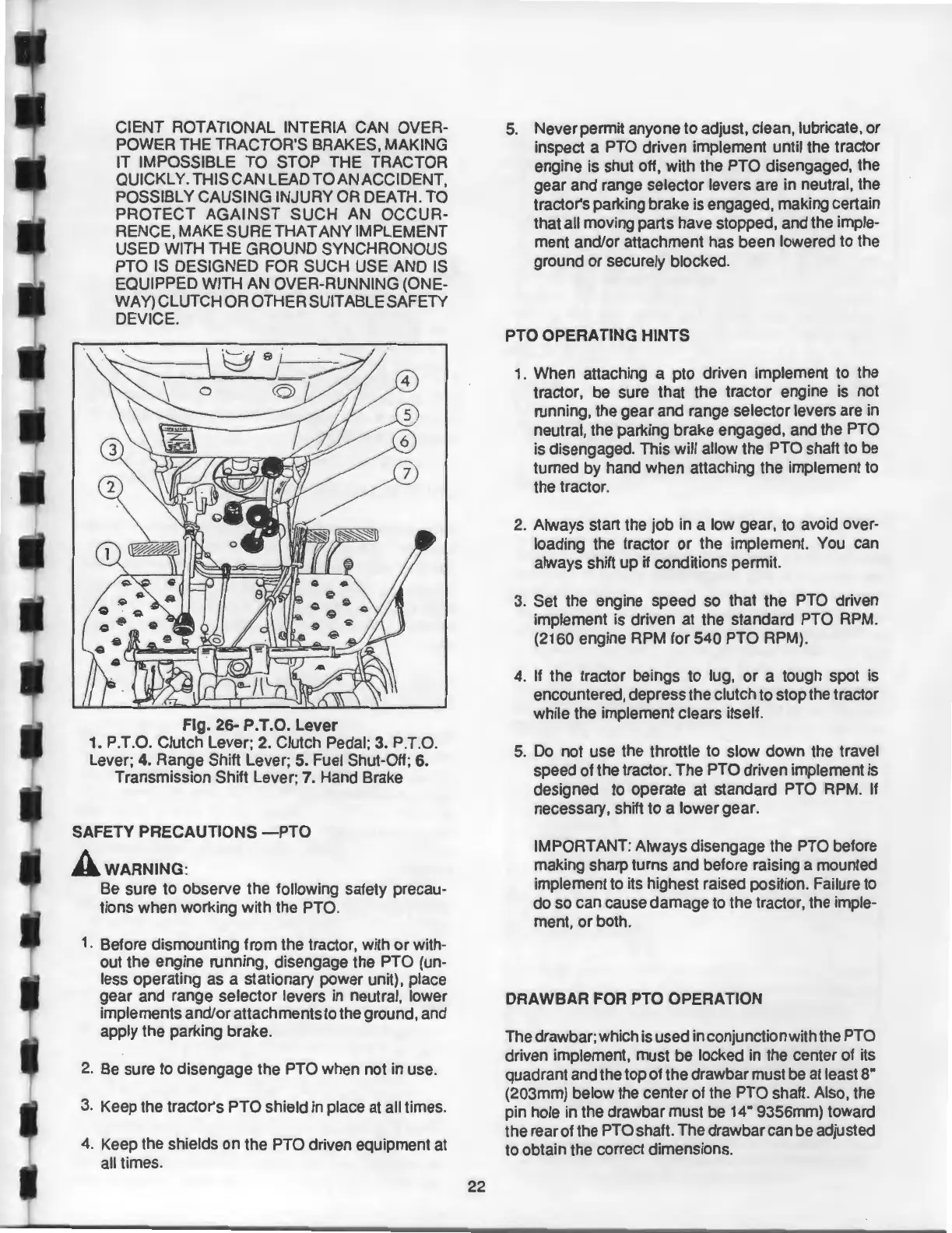

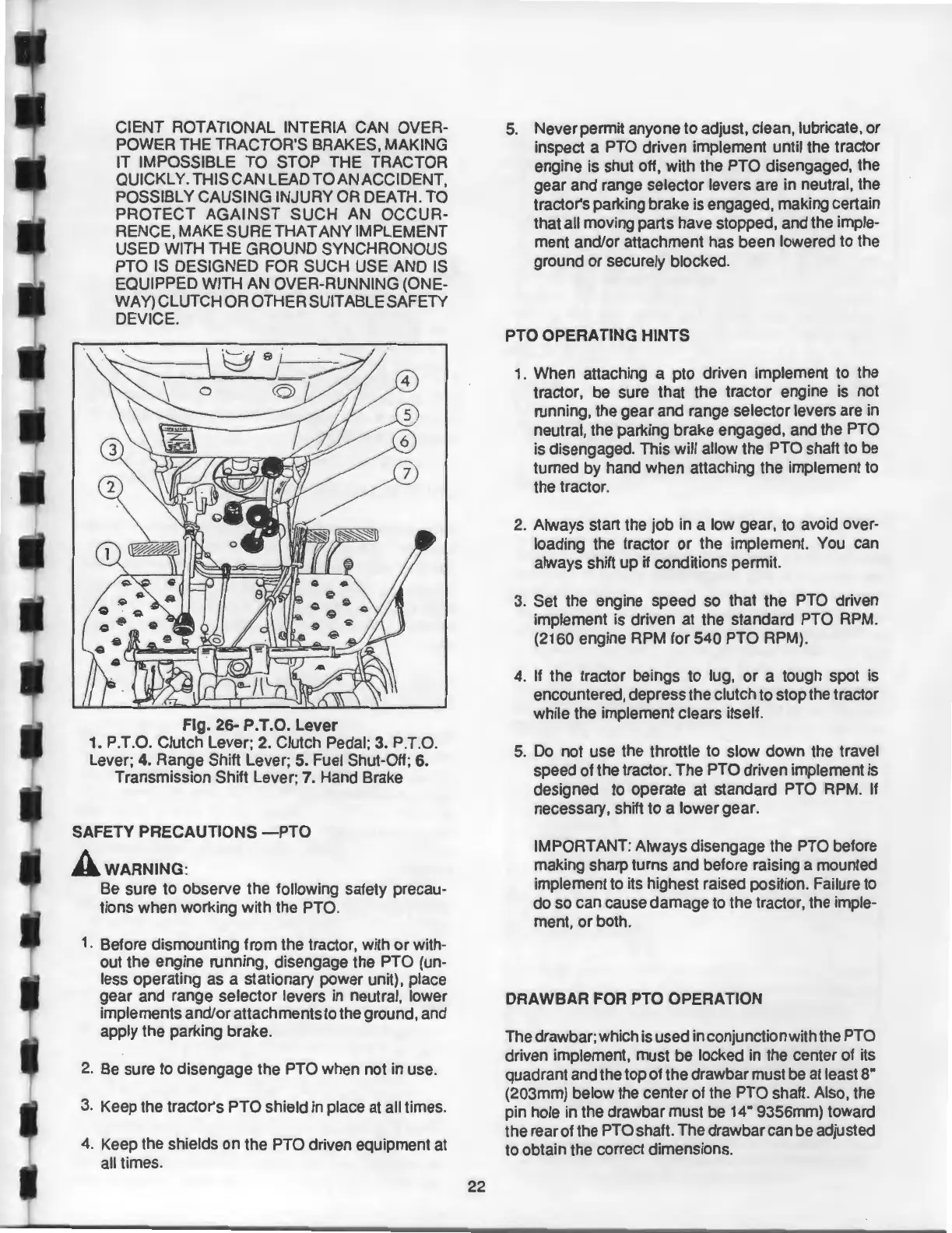

Fig.

26- P.T.O.

Lever

1. P.T.O. Clutch Lever; 2. Clutch Pedal; 3. P.T.O.

Lever;

4. Range Shift Lever; 5. Fuel Shut-Off; 6.

Transmission Shift Lever; 7. Hand Brake

SAFETY PRECAUTIONS

-PTO

A

wARNING:

Be

sure to observe the following safety precau-

tions when working with the PTO.

1.

Before dismounting from the tractor, with

or

with-

out the engine running, disengage the PTO (un-

less operating as a stationary power unit), place

gear and range selector levers in neutral, lower

implements and/or attachments to the ground, and

apply the parking brake.

2. Be sure to disengage the PTO when not in use.

3. Keep the tractor's PTO shield in place at all times.

4.

Keep the shields on the PTO driven equipment at

all times.

22

5.

Never permit anyone to adjust, clean, lubricate,

or

inspect a PTO driven implement until the tractor

engine is shut off, with the PTO disengaged, the

gear and range selector levers are in neutral, the

tractor's parking brake is engaged, making certain

that all moving parts have stopped, and the imple-

ment and/or attachment has been lowered to the

ground

or

securely blocked.

PTO OPERATING HINTS

1.

When attaching a pto driven implement to the

tractor, be sure that the tractor engine is not

running, the gear and range selector levers are in

neutral, the parking brake engaged, and the PTO

is disengaged. This will allow the PTO shaft to be

turned by hand when attaching the implement to

the tractor.

2. Always start the job in a low gear, to avoid over-

loading the tractor

or

the implement. You can

always shift up if conditions permit.

3. Set the engine speed so that the PTO driven

implement is driven at the standard PTO RPM.

(2160 engine RPM

for

540 PTO RPM).

4.

If the tractor beings to lug,

or

a tough spot is

encountered, depress the clutch to stop the tractor

while the implement clears itself.

5.

Do

not use the throttle to slow down the travel

speed of the tractor. The PTO driven implement

is

designed to operate at standard PTO RPM. If

necessary, shift to a lower gear.

IMPORTANT: Always disengage the PTO before

making sharp turns and before raising a mounted

implement to its highest raised position. Failure to

do so can cause damage to the tractor, the imple-

ment, or both.

DRAWBAR FOR PTO OPERATION

The drawbar; which is used in conjunction with the PTO

driven implement, must be locked in the center of its

quadrant and the top of the drawbar must

be

at

least 8"

(203mm) below the center of the PTO shaft. Also, the

pin hole in the drawbar must be 14" 9356mm) toward

the rear of the PTO

shaft. The drawbarcan be adjusted

to obtain the correct dimensions.

Loading...

Loading...