Pump Installation 5756 Pump Installation

L4

L2

L1

L6L3

L5

5050

77

77

50

EN EN

3 m

Filter

tape

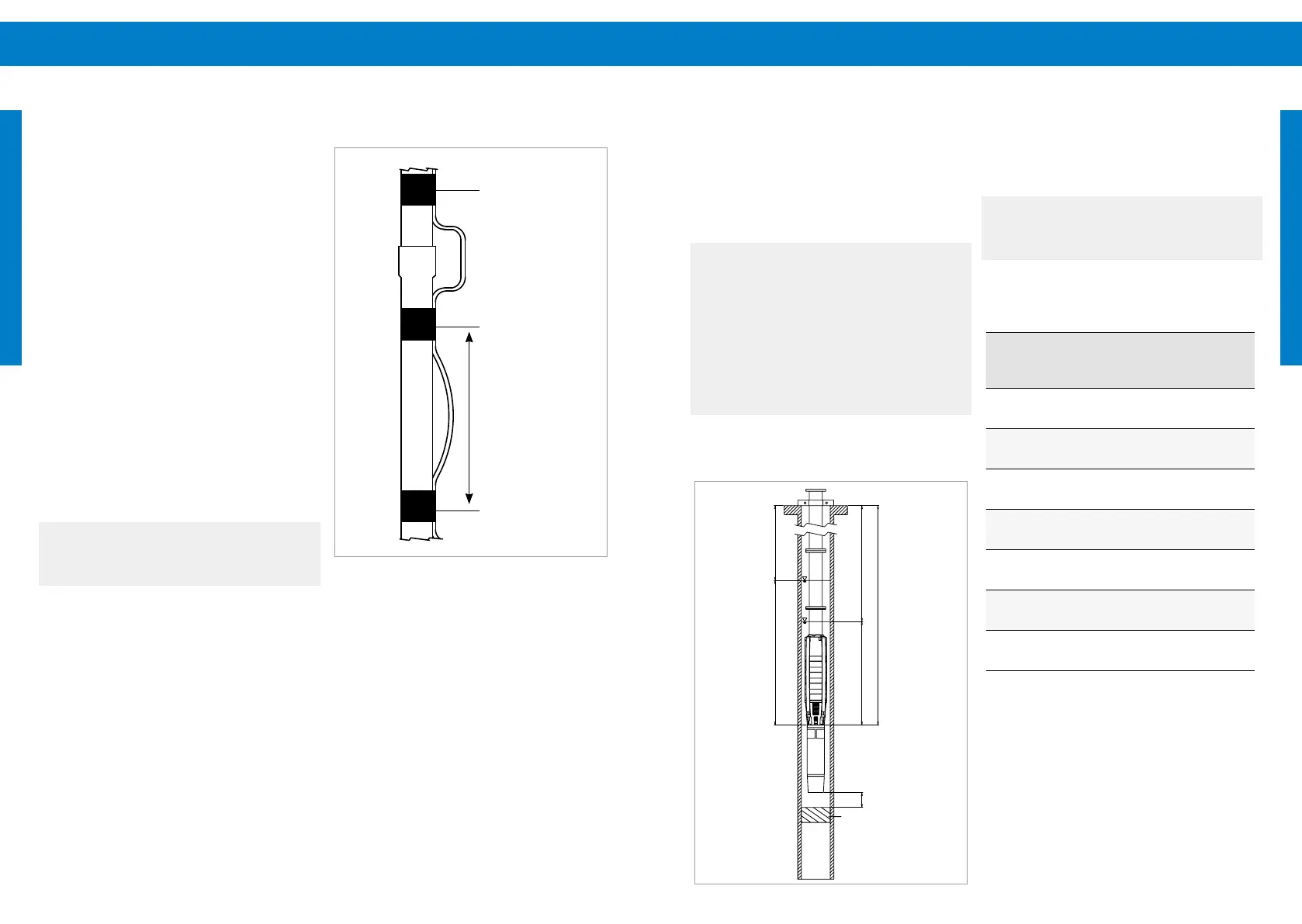

8.2.5 Installation Depth

Make sure that the pump unit is suspended properly

and is not in contact with sand and mud from the

well bottom. It is recommended to install the pump

above the lter zone (= water entry zone) of the well

to keep the sand content in the water low and ensure

proper cooling of the motor, see also "Figure 22:

Installation depth" on page 57.

a

CAUTION – The pump must be

submerged completely. Never let the

pump run dry. Dry running will damage

the pump and void the warranty.

LORENTZ prescribes a dry run protection

for every pump system.

CAUTION – If the pump does not

hang above the lter zone a ow sleeve is

necessary.

Figure 22: Installation depth

8.2.6 Removal

If you have to remove the pump system it is the

same principle as the installation in reverse order.

When removing the pump the pipes will be full of

water and will be heavier.

a

CAUTION – When you lift the pump

system out of the well the pipes are full

of water. This causes additional weight.

In the table below you can see the additional weight

of the water per meter pipe length.

Table 11: Additional weight per meter pipe length

Pipe

diameter

Additional weight

[in] [kg/m] [lb/ft]

2 2.0 14.5

2.5 3.2 23.1

3 4.6 33.3

4 8.2 59.3

5 12.7 91.9

6 18.4 133.1

L1: Installation depth

L2: Max immersion depth = 150m

L3: Min immersion depth = 1m

L4: Distance to lter

L5: Depth to highest water level

L6: Depth to lowest water level

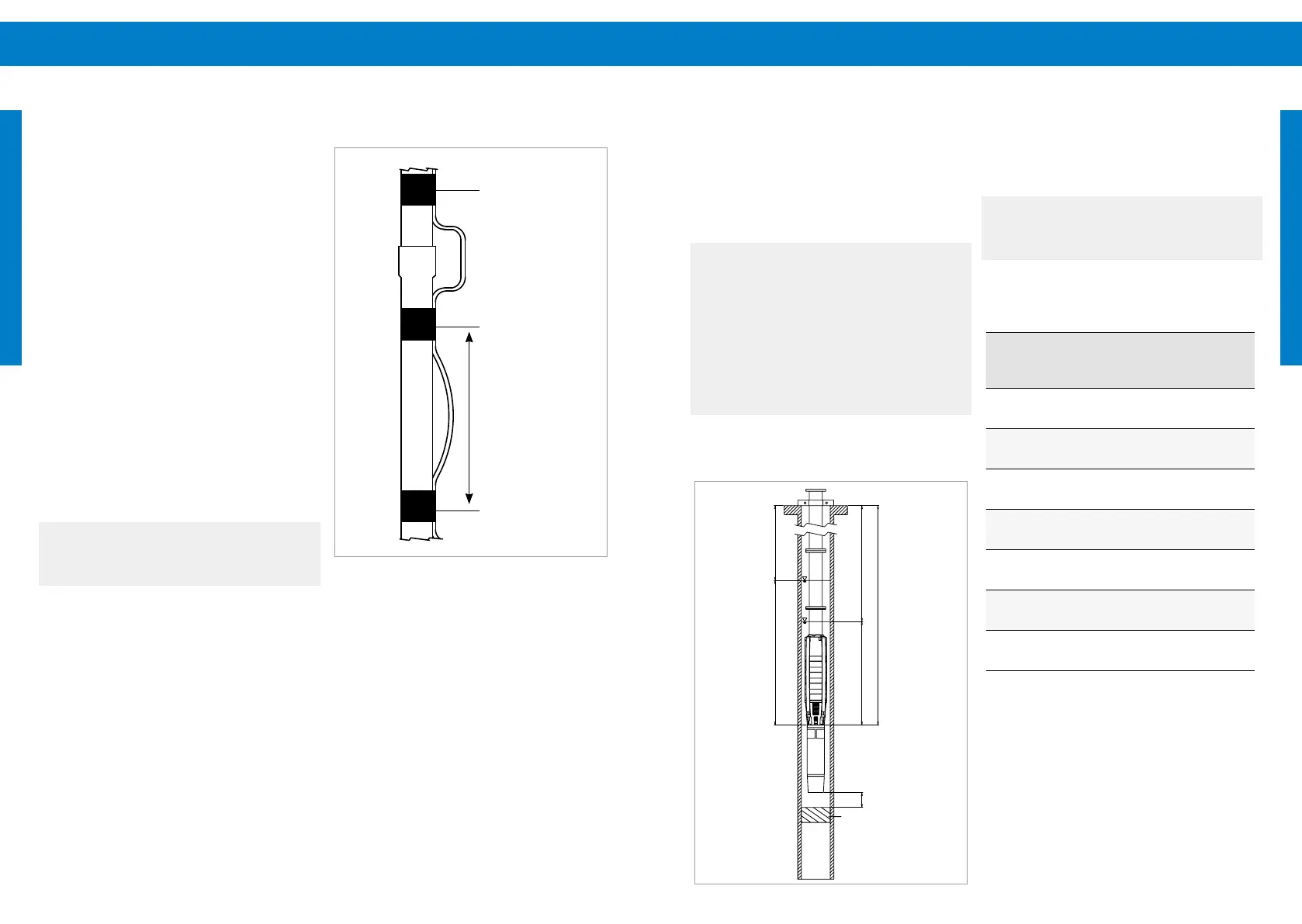

During the process of lowering the pump into the

well the motor cable has to be xed properly to the

pipe, see "Figure 21: Fixing of the motor cable at a

joint and a strait pipe" on page 56.

Where a plastic pipe is used, the longitudinal stretch

of the pipe under load has to be considered by

leaving a sucient gap between the pipe and the

cable!

The cable should be xed with water-resistant tape.

It is a good installation practice to form a loop with

the motor cable near the pump and repeat it about

every 40 m / 130 ft along the riser pipe. This will keep

any tensile forces away from the motor cable.

To extend the motor cable pay attention to chapter

„8.1.2 Cable Splicing“ on page 50.

Round o the edges of a ange to prevent damage

to the cable. Do not x the cable tightly. Leave space

for the pipes to expand. The cable needs to get xed

every 3 m.

a

NOTE – Measuring and noting down the

distances between the xing will help to

lower the pump to the right depth.

Figure 21: Fixing of the motor cable at a joint and a

strait pipe

Loading...

Loading...