MADE IN ITALY

18

electric modular oven

Water in excess is discharged through a pipe located in the front - lower side of the oven.

Diameter and precise position of the drain pipe are included in the technical data sheet. It is

recommended that discharge pipes is slightly pointing downwards and does not exceed 2-3mts

Unpleasant smells can be avoided by including a syphon in the sewage connection

Vapour expelled from the baking chamber is released in the atmosphere through the vapour duct

which must be installed on the top pressing part of the exhauster.

The vapours discharge duct must not be connected to the fume stack, and must have its own exit

which can be near but should not communicate with the combustion fume stack.

We recommend that you build a duct as linear as possible, with very few elbows and long linear

sections. At the bottom of each rising element of the vapour exhauster, a collecting chamber must

be included with a condensation draining pipe. Special openings must be arranged in order to

facilitate inspections and cleaning.

The use of stainless steel ducts is recommended and preferential.

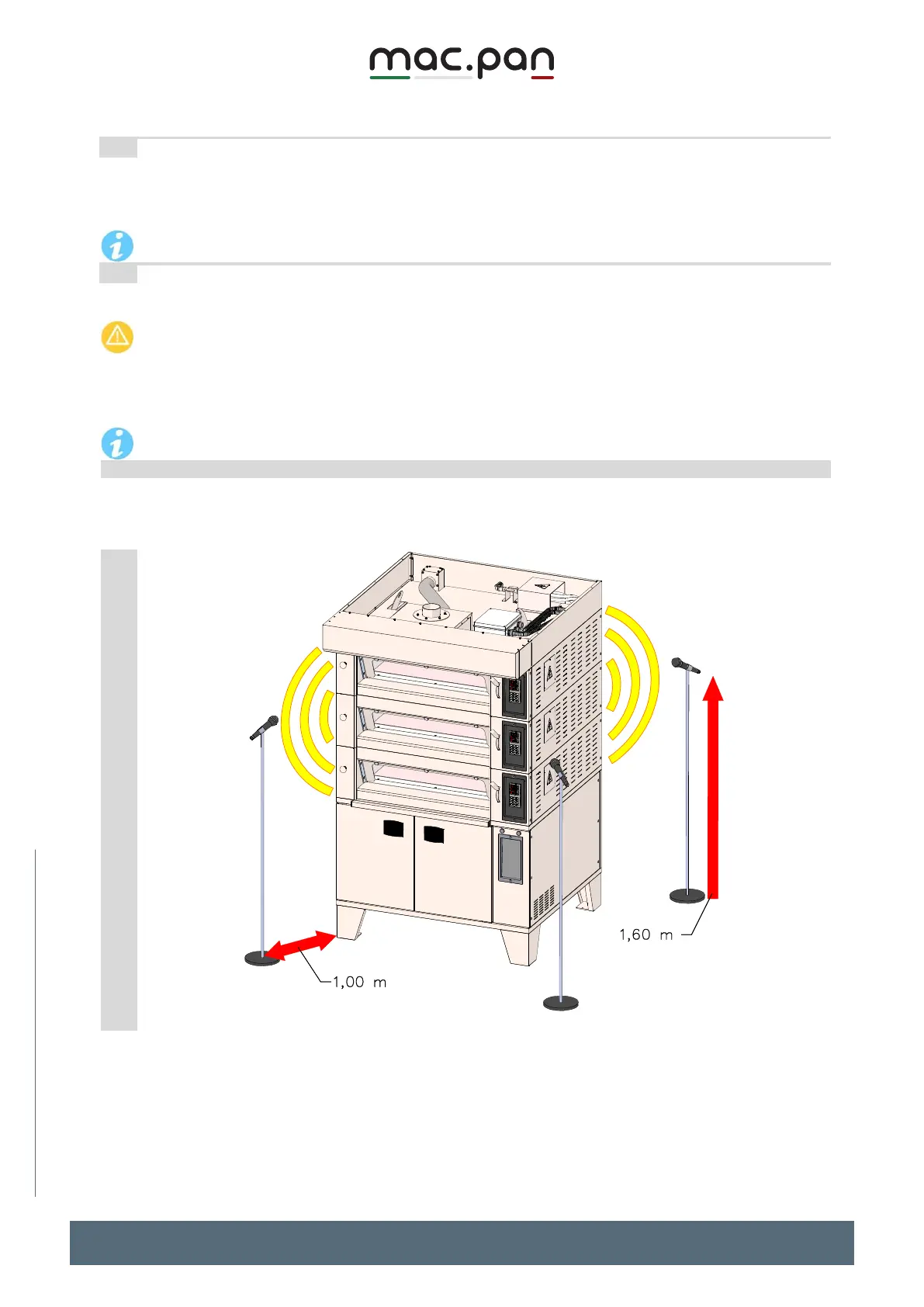

The oven has been designed to reduce risks from noise emissions to the minimum possible.

Surveys and inspections done on our ovens at the worst working conditions give the equivalent

continuous A-weighted sound pressure to be LOWER than

FIG.7

The measurement has been taken at 1.6 mts height from the floor level and 1 mt from the front

side

Loading...

Loading...