13

57-600 Eclipse

®

Guided Wave Radar Transmitter

2. Ratio of Diameter: Length (A:B) is 1:1 or greater; any

ratio <1:1 (e.g., a 2"× 6" nozzle = 1:3) may require a

Blocking Distance and/or DIELECTRIC adjustment

(see Section 2.6.5.2 Measurement Type: Level and

Volume).

3. No pipe reducers (restrictions) are used.

• Probe is kept away from conductive objects to ensure proper

performance. See Probe Clearance Table below. A lower gain

(increase in DIELECTRIC setting) may be necessary to

ignore certain objects (see Section 2.6.5.4 Measurement

Type: Interface and Volume).

2.4.3.1 To install a Model 7xF rigid single rod probe:

➀ Make sure the process connection is at least 2" NPT or a

flanged mounting.

➁ Carefully place the probe into the vessel. Align the gasket

on flanged installations.

➂ Align the probe process connection with the threaded or

flanged mounting on the vessel.

➃ For threaded connections, tighten the hex nut of the probe

process connection. For flanged connections, tighten flange

bolts.

➄ Probe can be stabilized by placing into a non-metallic cup

or bracket at the bottom of the probe. A TFE bottom

spacer (P/N 89-9114-001) is optional for mounting into

a metallic cup or bracket.

NOTE: If the transmitter is to be installed at a later time, do not remove

the protective cap from the probe. Do not use sealing com-

pound or TFE tape on probe connection to transmitter as this

connection is sealed by a Viton

®

O-ring.

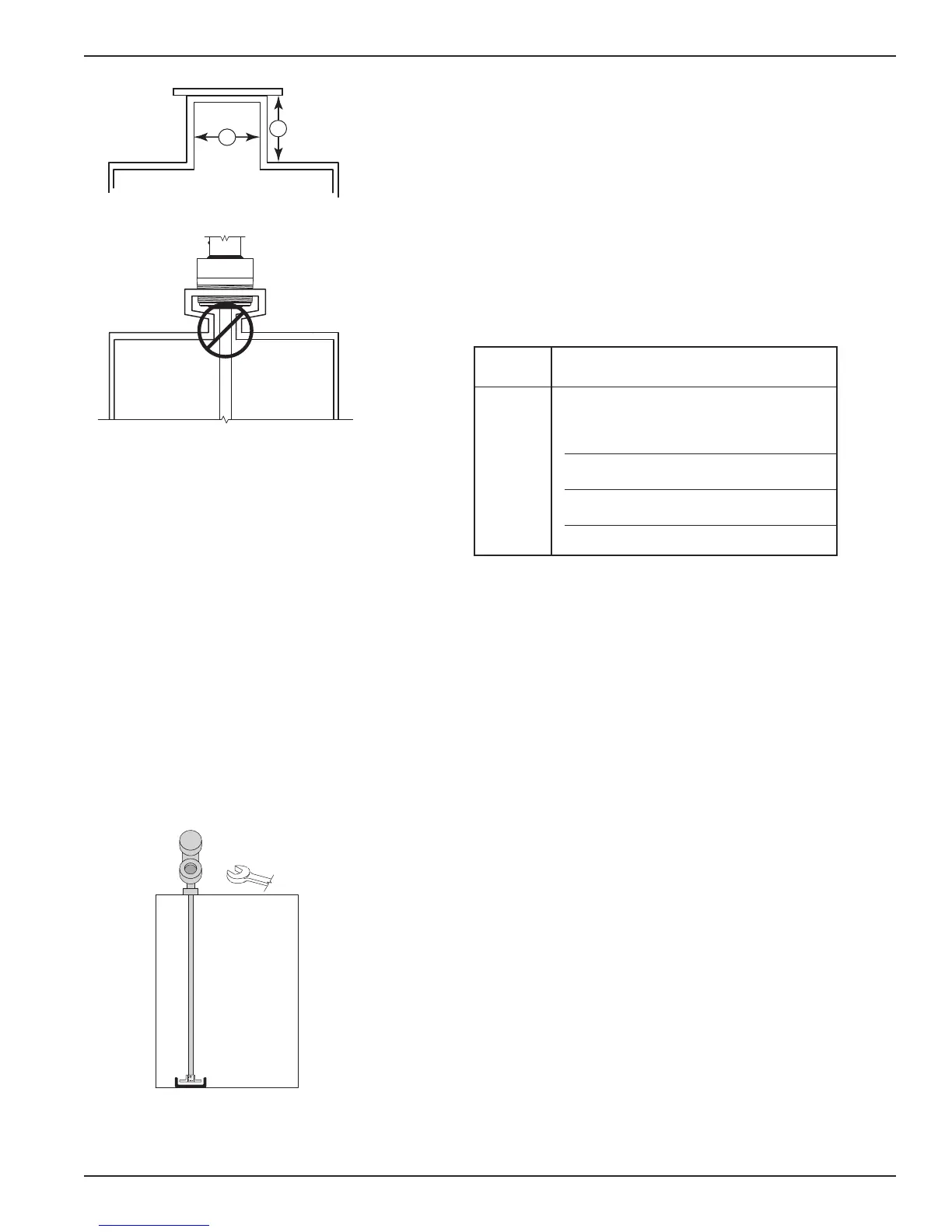

2.4.3.2 To install a Model 7x1 flexible single rod probe:

➀ Make sure the process connection is at least 2" NPT or a

flanged mounting.

➁ Carefully place the probe into the vessel. Align the gasket

on flanged installations.

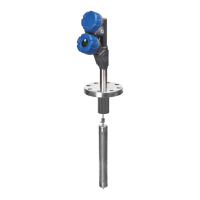

Distance

to Probe Acceptable Objects

<6" Continuous, smooth, parallel conductive

surface, for example a metal tank wall;

important that probe does not touch wall

>6" <1" (25mm) diameter pipe and beams,

ladder rungs

>12" <3" (75mm) diameter pipe and beams,

concrete walls

>18" All remaining objects

PROBE CLEARANCE TABLE

Loading...

Loading...