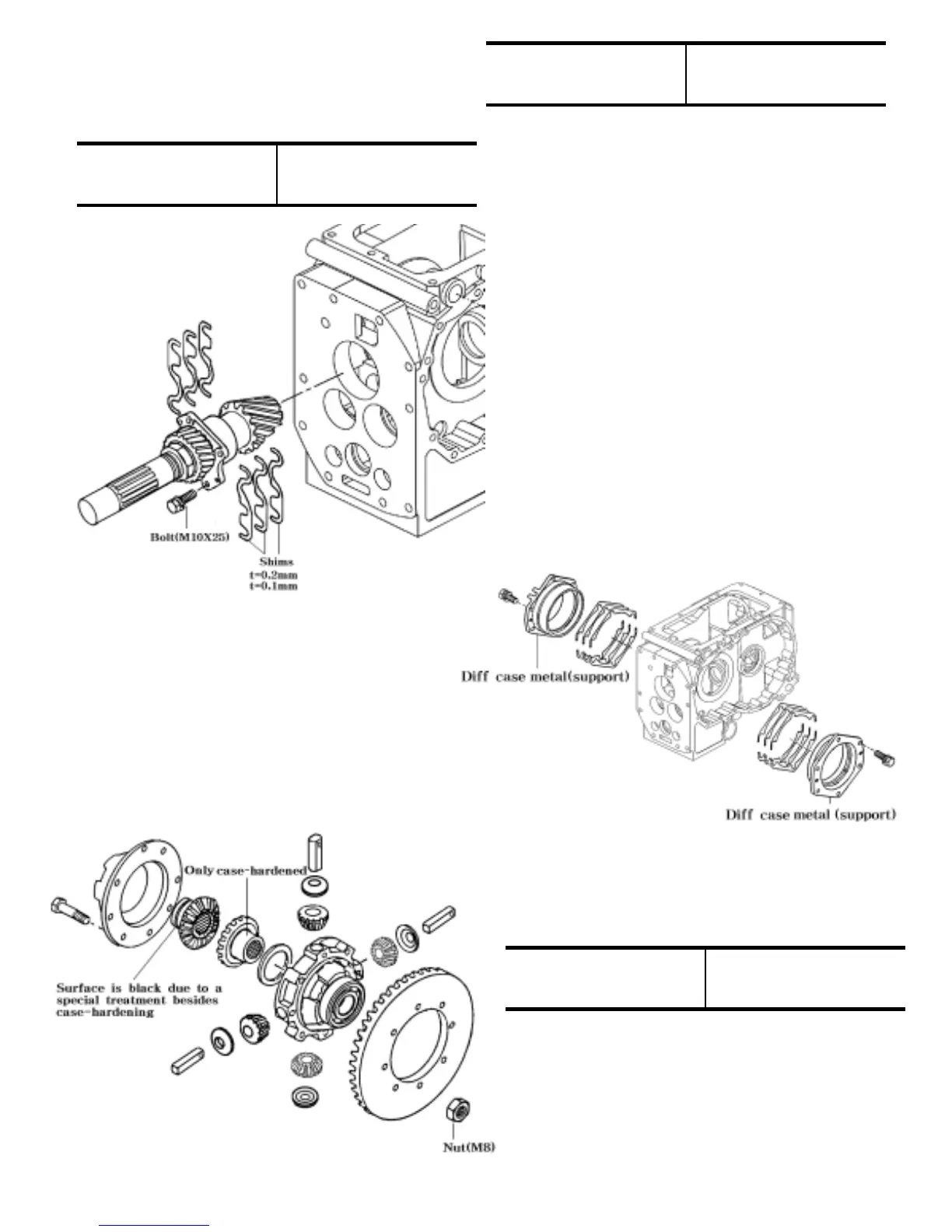

When the drive pinion or the ring gear has been

replaced, the proper number of shims to be

installed should be determined based upon the

following procedure:

9.0-11 Kgf.m

(39.8-69 ft.lbs)

Ring gear tightening

torque

5.5-7 Kgf.m

(39.8-69 ft.lbs)

Drive pinion metal

tightening torque

Fig.5-34

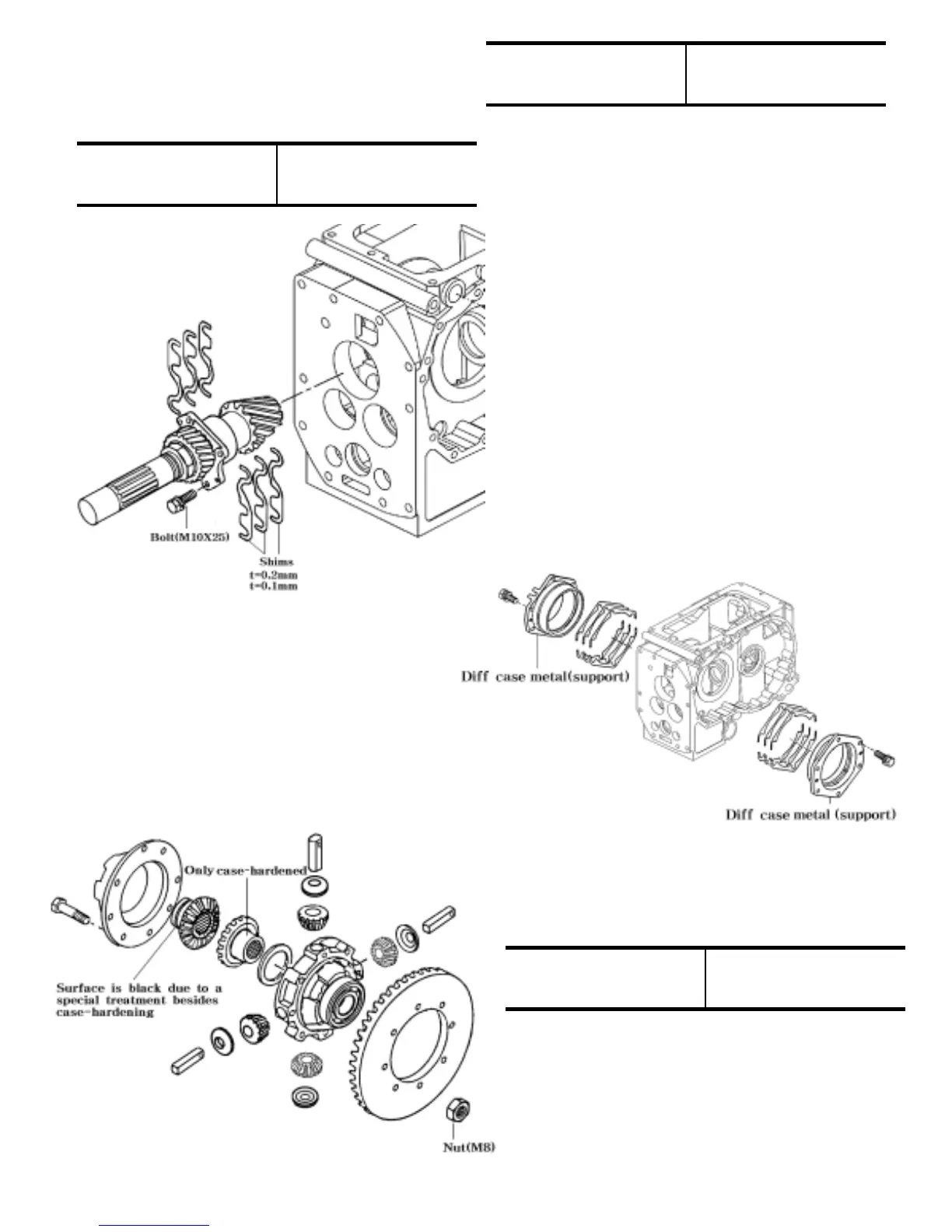

Note:

- As shown in Fig5-34,there are two kinds of

differential side gears.Although are case

hardened,the one installed on the side of the

diff-lock is treated further and colored black.

Take care not to mix them when assembling.

- Apply multi-purpose,quality grease to the

parts mentioned below:

• Tooth surfaces of dif-pinions and dif-side

gears

• Friction surfaces of dif-pinion shafts and

dif-pinions.

f.The Backlash between dif-pinion and dif-side

gear should be within as range of 0.1 to

0.2mm(0.004-0.008 in) and these parts

should turn smoothly.

Note:

When assembling without replacing the pinion

gear and ring gear with new ones,provide the

same shimming thickness as that provided before

disassembly.

e. Install the differential gears.

g. Install the differential gear assembly.

5.5-7 Kgf.m

(39.8-69 ft.lbs)

Diff-case metal

tightening torque.

5-29

Fig.5-33

Fig.5-35

Loading...

Loading...