GROVE Published 10-21-2010, Control# 198-04 10-27

5540F/YB5515 SERVICE MANUAL STEERING SYSTEM

9. New piston on a predrill cylinder rod.

a. Re-drill and dowel BOTH the piston and cylinder rod

at 90° from the existing drilled dowel hole in the

cylinder rod. Follow procedures in step 8.

10. New cylinder rod installed to a predrilled piston.

Use the predrilled hole in the piston. Care must be taken

not to elongate the existing hole in the piston.

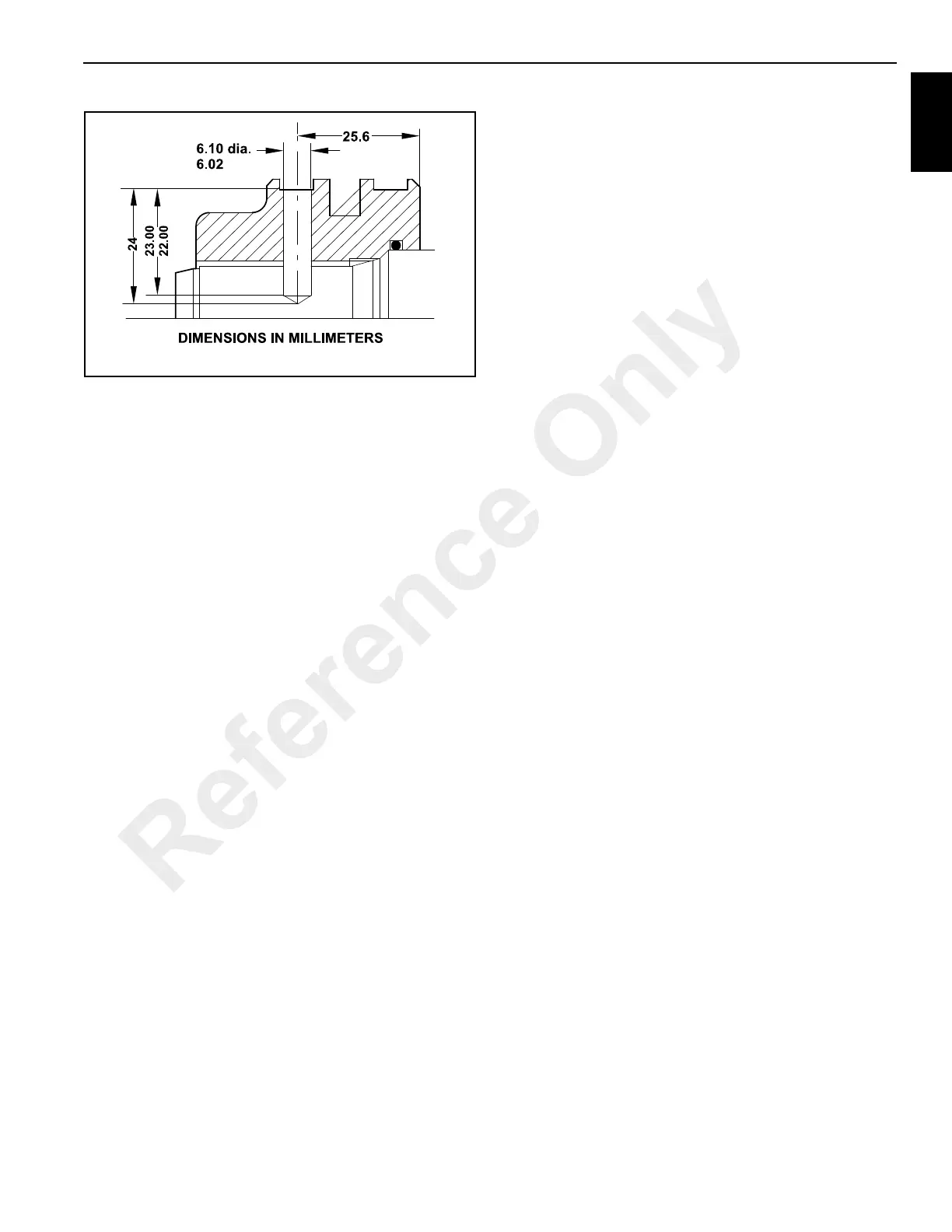

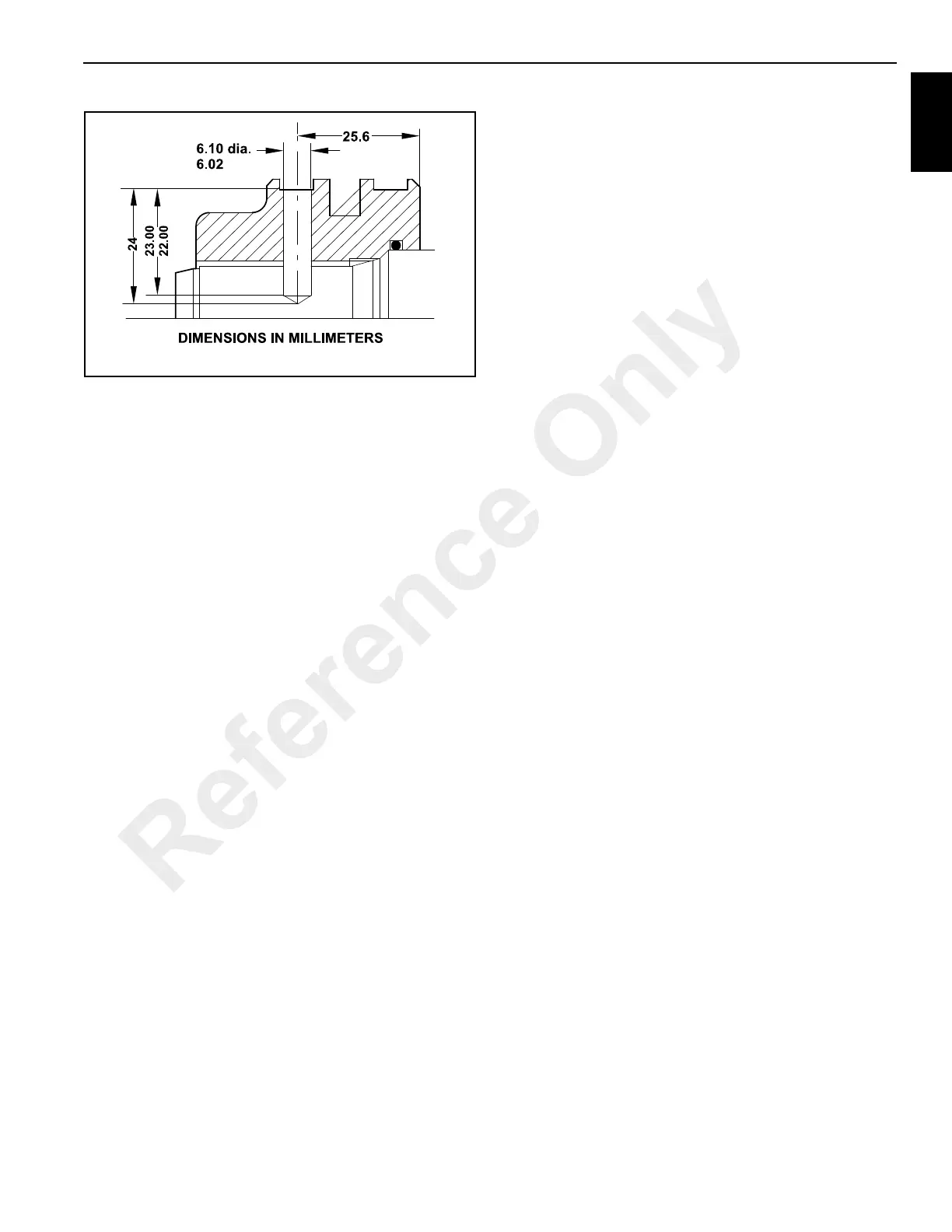

a. Using a 6 mm drill make a center mark in the

cylinder rod. DO NOT drill the cylinder rod at this

time.

b. Use an undersized diameter drill bit to drill a guide

hole to the depth of 24 mm Figure 10-36. Make sure

the drill bit is centered correctly on the center mark

made in Step A.

c. Use a 6 mm drill bit and drill a hole to the depth of

the guide hole.

d. Remove all swarl and contamination. Install dowel 8

Figure 10-32.

11. Install wear ring 10 and piston seal 9 onto piston 7.

12. Carefully insert the assembled cylinder rod into the

cylinder barrel. Use care to prevent damage to the

piston seal and wear ring during installation. Work the

piston rod straight into the cylinder barrel.

13. Apply Loctite 932 to the first three threads of the end

cap. Slide the end cap into the cylinder barrel and

engage the threads. Tighten the end cap with the

spanner wrench to a torque of 500 lb-ft (678 Nm).

NOTE: If hydraulic oil contacts uncured Loctite a

weakening of the bond will result. Cure times vary

according to the ambient temperature and the type

of activator used. The curing time for Loctite 932

and Activator T at an ambient temperature of 68° F

(20° C) is two hours. Do not apply oil to the cylinder

before this time.

14. Fill and test the cylinder.

Installation

1. Locate the steering cylinder on the axle.

2. Apply anti-seize compound to pivot pins and install in

both the rod end and base end of the cylinder.

3. Install locking bolts to hold pins in place.

4. Connect the hydraulic hoses to the cylinder.

5. Lubricate the grease fitting with Lithium based, E.P. No.

2 bearing grease.

6. Check the hydraulic oil level and add oil if necessary.

7. Start the engine and operate the cylinder(s) through

several complete cycles to remove air from the system.

Operate the cylinders slowly and do not let them hit

bottom until movement is positive in both directions.

After the circuit is filled with oil, the cylinders can be

operated normally.

8. Check for leaks and repair if necessary.

9. Check the hydraulic oil level and fill if necessary.

Reference Only

Loading...

Loading...