11-37

5540F/YB5515 SERVICE MANUAL STRUCTURALS

15. Stand winch on motor end with bearing support up. Then

remove eight (8) bearing support capscrews and

bearing support being careful to avoid damaging the

sealing or bearing surfaces.

16. Slide drum cut of base onto a work bench and remove

seal and bearing from support end.

17. Thoroughly clean and inspect drum and base.Check

ring gear (machined into inside surface of drum) teeth

for nicks, spalling or excessive wear. Replace if wear is

greater than 0.015 in. (0.4 mm) when compared to

unworn area of teeth.

Assembly

NOTE: Winches with a three piece fabricated base special

shoulder capscrews to fasten side plates the base

plate. DO NOT use standard capscrews in their

pace.

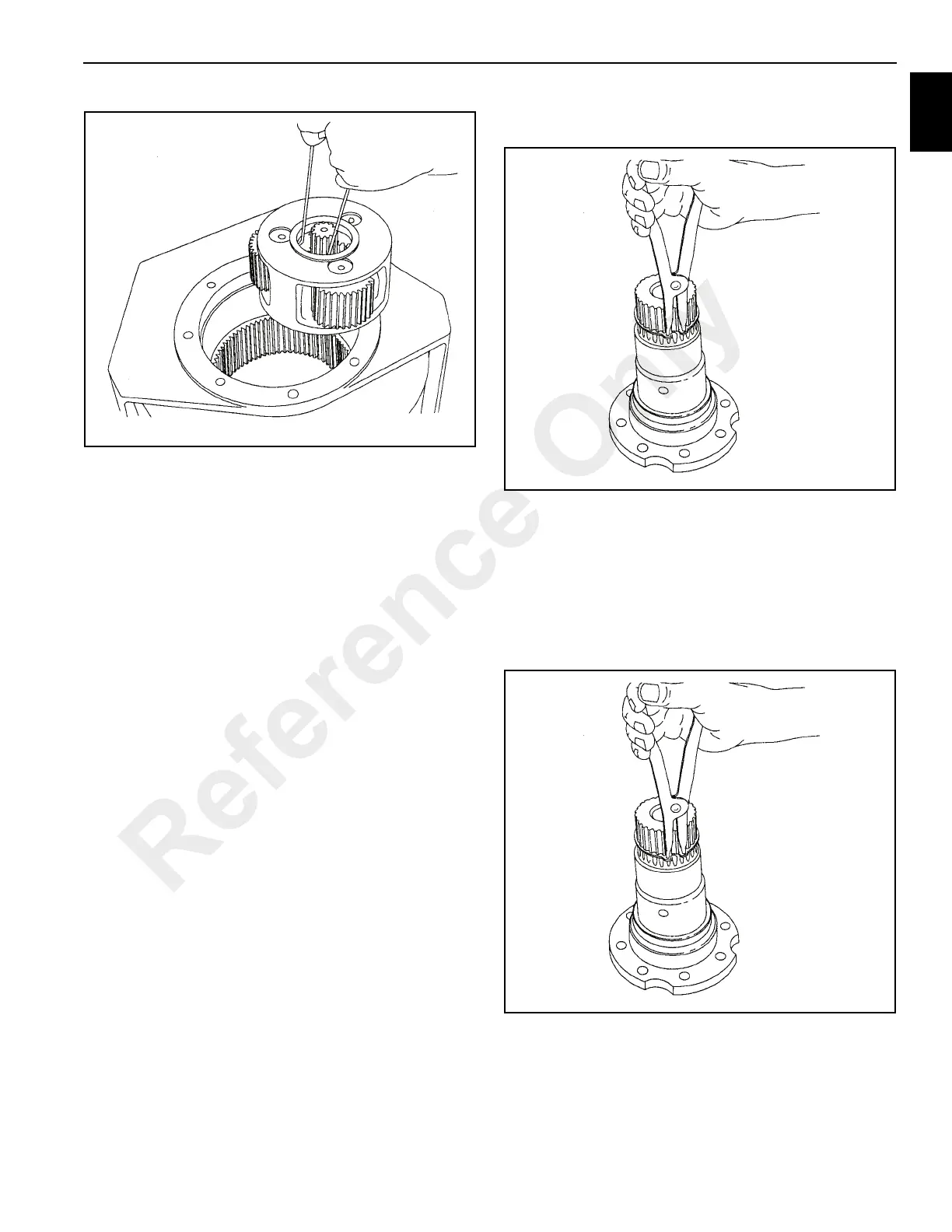

1. Place winch base on side with bearing supported up

(Figure 11-72).

2. Install a new bearing in the drum if replacement is

necessary. Apply a non-hardening sealant on the

outside diameter of the new seal. Install the spring side

of the seal next to the bearing, then press into he drum,

using a flat plate to avoid distortion. Be sure the drain

plug is installed correctly.

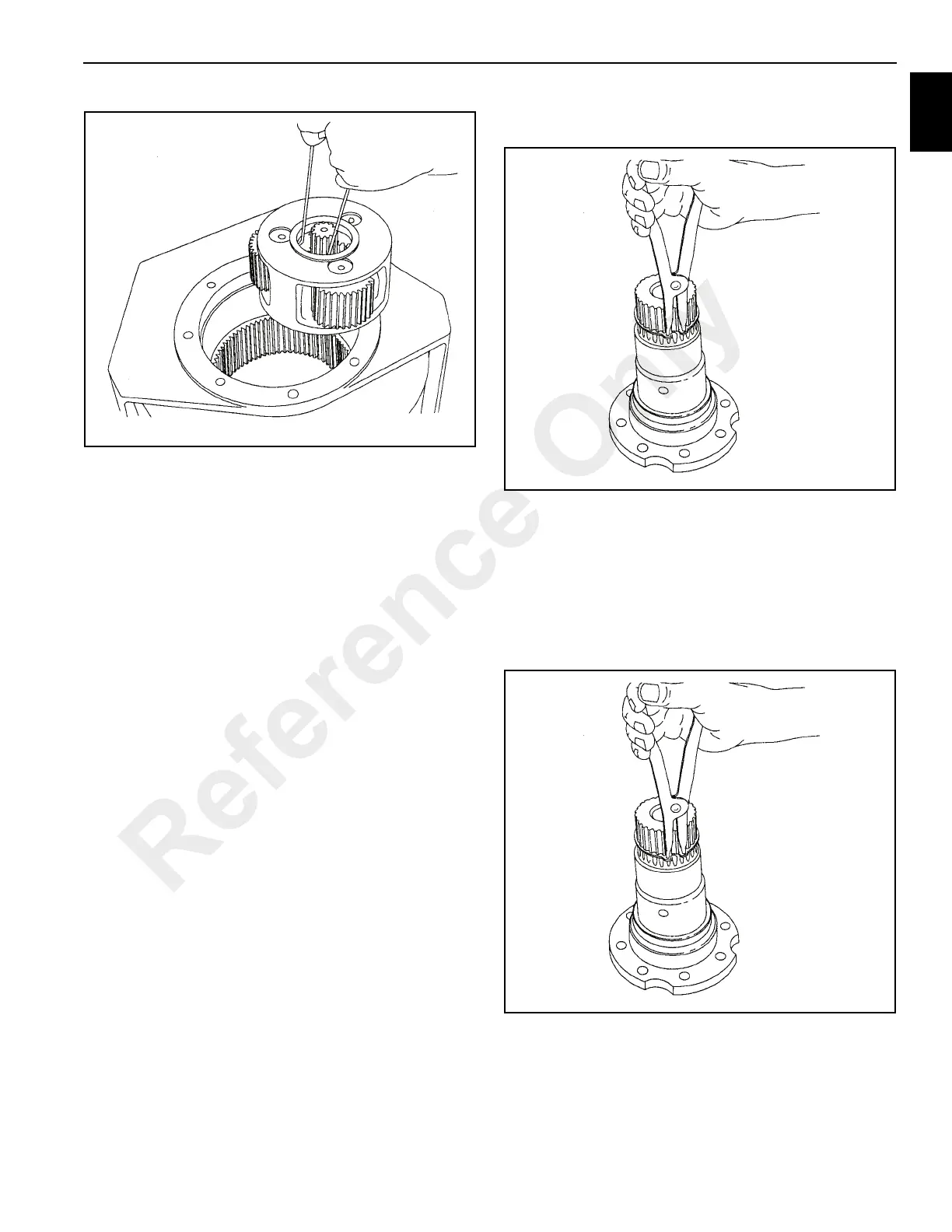

3. Install the snap ring on the bearing support

(Figure 11-73).

Make certain the snap ring is installed on the bearing

support. This snap ring will keep the output planet carrier

correctly positioned in the winch.Gear train damage may

occur if this snap ring is omitted.

Reference Only

Loading...

Loading...